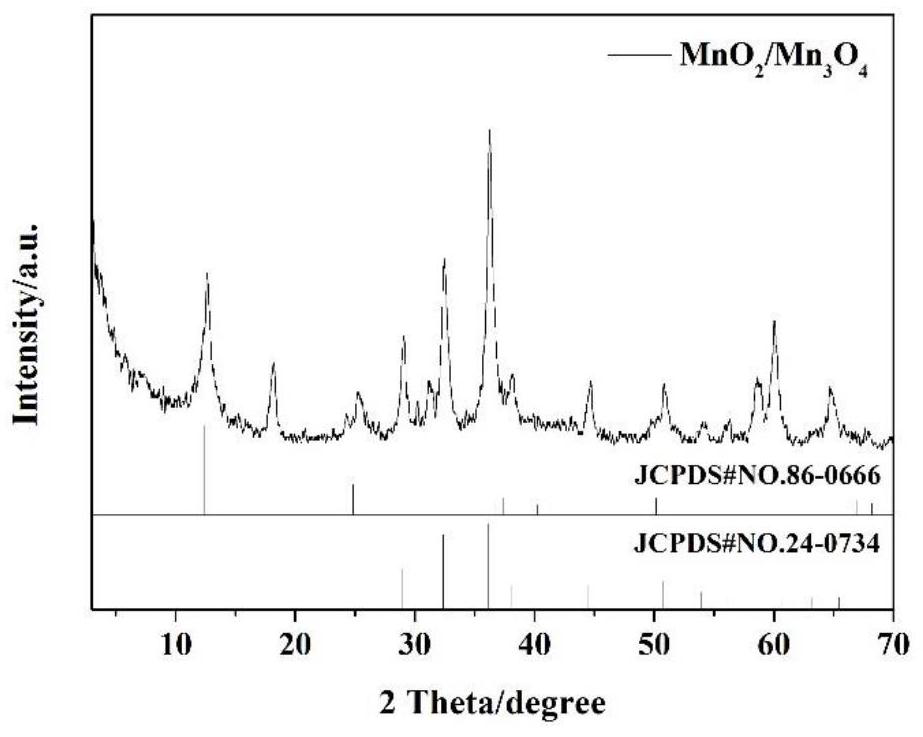

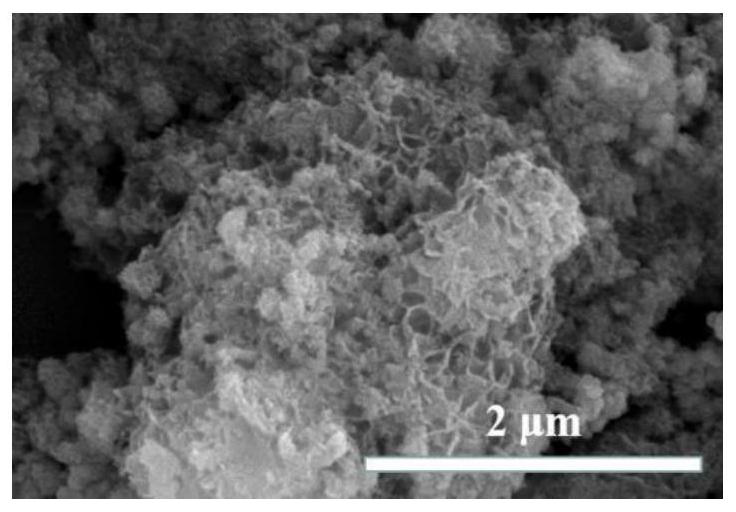

Method for preparing high-specific-capacity composite electrode material MnO2/Mn3O4

A composite electrode, high specific capacity technology, used in nanotechnology for materials and surface science, battery electrodes, circuits, etc., can solve problems such as high cost and complex preparation methods, achieve high charge-discharge specific capacity, and simple operation. , the effect of good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] MnO 2 / Mn 3 o 4 The preparation method of composite material, comprises the following steps:

[0030] Step 1: Weigh 0.034g MnSO 4 ·H 2 O with 0.19 g KMnO 4 , Measure 40mL of deionized water and prepare a mixed solution.

[0031] Step 2: Add 0.01 g of CH to the mixed solution 4 N 2 O, placed on a magnetic stirrer and stirred for 5min to make it evenly mixed.

[0032] Step 3: Pour the solution in step 2 into an autoclave with a solution volume of 40 ml, and heat at 160° C. for 16 h.

[0033] Step 4: Pour off the supernatant of the product obtained from the reaction, then put the resulting precipitate into a centrifuge tube, wash it with deionized water first, then wash it with absolute ethanol, repeat 3 times in turn, and then put it in a drying box at 70 Dry at ℃ for 7h to get MnO 2 / Mn 3 o 4 composite material.

Embodiment 2

[0035] MnO 2 / Mn 3 o 4 The preparation method of composite material, comprises the following steps:

[0036] Step 1: Weigh 0.05g MnSO 4 ·H 2 O with 0.15 g KMnO 4 , Measure 30mL of deionized water to prepare a mixed solution.

[0037] Step 2: Add 0.013 g of CH to the mixed solution 4 N 2 O, placed on a magnetic stirrer and stirred for 5min to make it evenly mixed.

[0038] Step 3: Pour the solution in step 2 into an autoclave with a volume of 30 ml, and heat at 180° C. for 12 hours.

[0039] Step 4: Pour off the supernatant of the product obtained from the reaction, then put the resulting precipitate into a centrifuge tube, wash it with deionized water first, then wash it with absolute ethanol, repeat 3 times in turn, and then put it in a drying box at 70 Dry at ℃ for 5h to get MnO 2 / Mn 3 o 4 composite material.

Embodiment 3

[0041] MnO 2 / Mn 3 o 4 The preparation method of composite material, comprises the following steps:

[0042] Step 1: Weigh 0.035g MnSO 4 ·H 2 O with 0.25 g KMnO 4 , Measure 37.5mL of deionized water to prepare a mixed solution.

[0043] Step 2: Add 0.017 g of CH to the mixed solution 4 N 2 O, placed on a magnetic stirrer and stirred for 5min to make it evenly mixed.

[0044] Step 3: Pour the solution in step 2 into an autoclave with a solution volume of 30 ml, and heat at 150° C. for 18 hours.

[0045] Step 4: Pour off the supernatant of the product obtained from the reaction, then put the obtained precipitate into a centrifuge tube, wash it with deionized water first, then wash it with absolute ethanol, repeat 3 times in sequence, and then put it in an oven to dry for 6 hours. get MnO 2 / Mn 3 o 4 composite material.

PUM

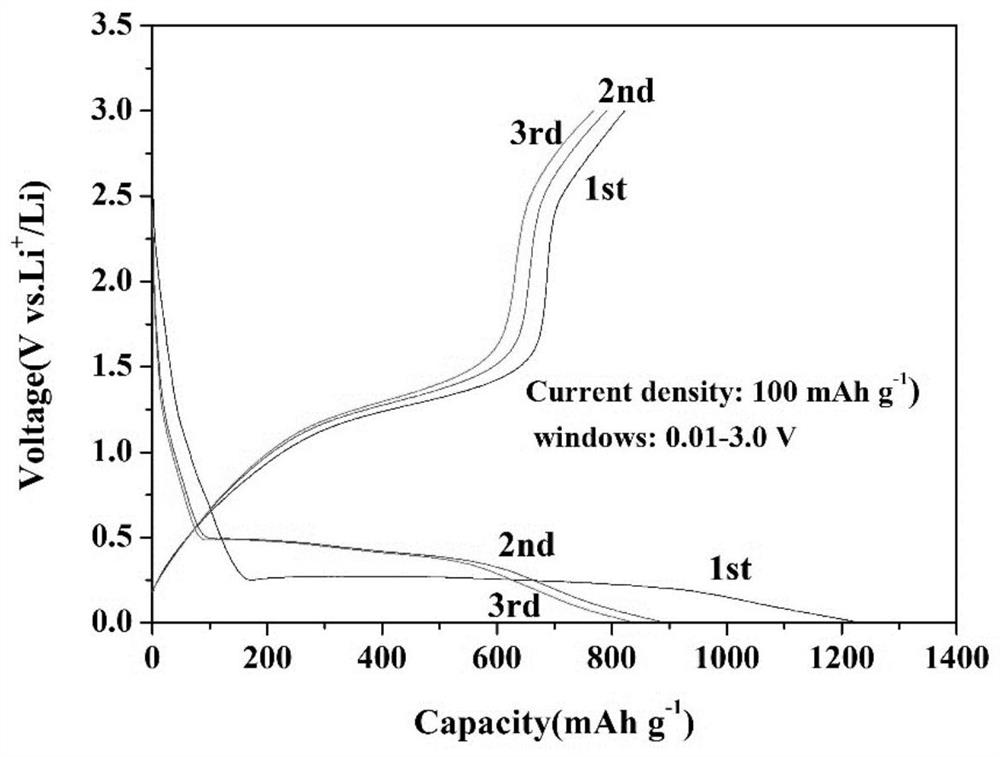

| Property | Measurement | Unit |

|---|---|---|

| Charging capacity | aaaaa | aaaaa |

| Capacity | aaaaa | aaaaa |

| Charge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com