Constant-tension yarn feeder

A yarn feeder, constant tension technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problem that the real-time adjustment and control of yarn tension detection cannot be effectively matched and realized, and the tension balance cannot be effectively realized. Controlling yarn feeding, poor sensitivity of tension sensor, etc., to achieve the effect of stable and balanced tension control yarn feeding, precise and efficient adjustment control, and high pressure detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described in conjunction with accompanying drawing and specific embodiment now, wherein single-chip microcomputer control circuit, rotary encoder, first magnet, the motor that feeds yarn and feed super yarn, motor drive control circuit, display screen, tension setting circuit and power supply The circuits are all existing module parts, so only the innovative design of the present invention will be described in the following embodiments.

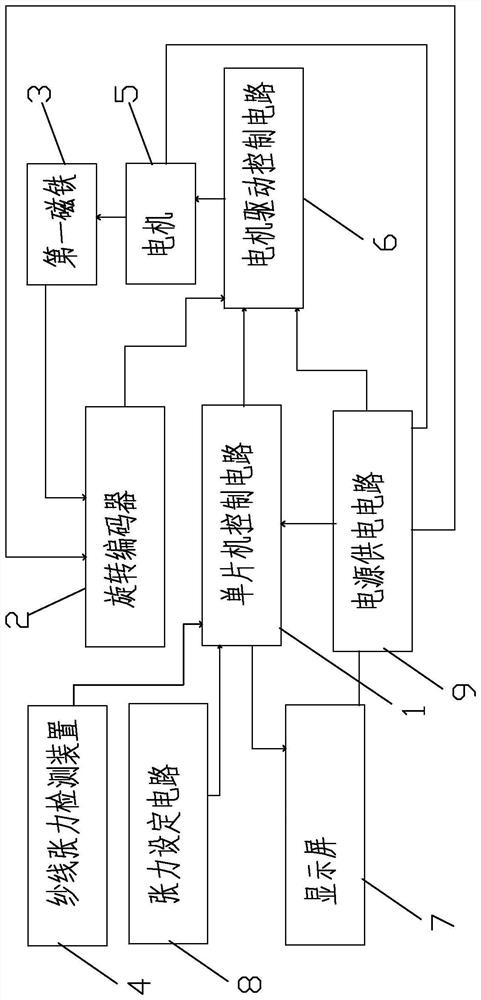

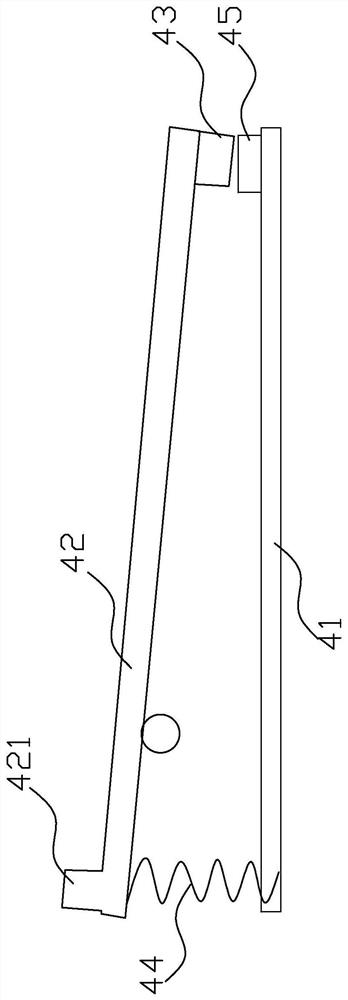

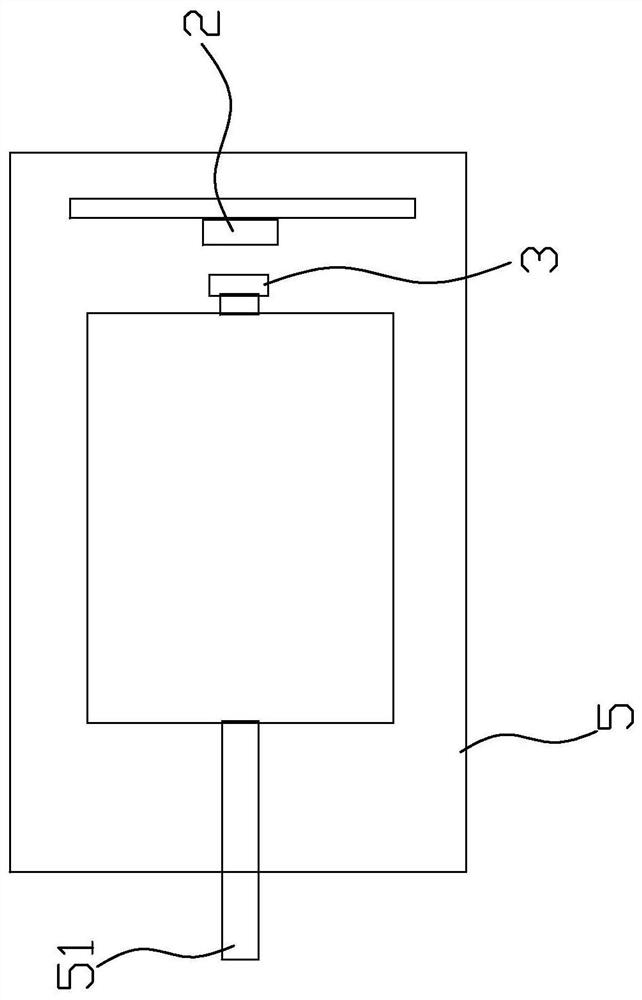

[0017] refer to Figure 1-Figure 7 , the preferred constant tension yarn feeder of the present invention includes a single-chip microcomputer control circuit 1, a rotary encoder 2, a first magnet 3, a motor 5 for yarn feeding and super yarn feeding, a motor drive control circuit 6, a display screen 7, and a tension setting device. Fixed circuit 8, power supply circuit 9 and yarn tension detection device 4, described single-chip microcomputer control circuit 1 is made of single-chip microcomputer STM32F1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com