An environmental protection anti-scratch cleaning device for rail transit vehicles

A rail transit vehicle and cleaning device technology, which is applied in the field of rail transit vehicle environmental protection anti-scratch cleaning device, can solve the problems of vehicle scratches, lack of brush internal cleaning structure, and affect the cleaning effect of rail vehicles, so as to improve the cleaning efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

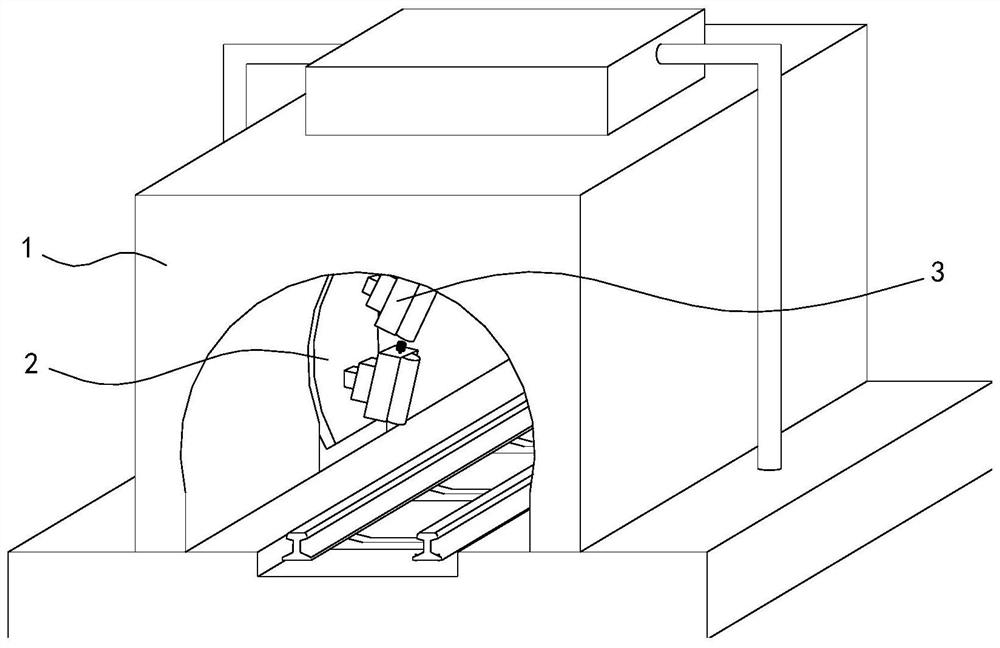

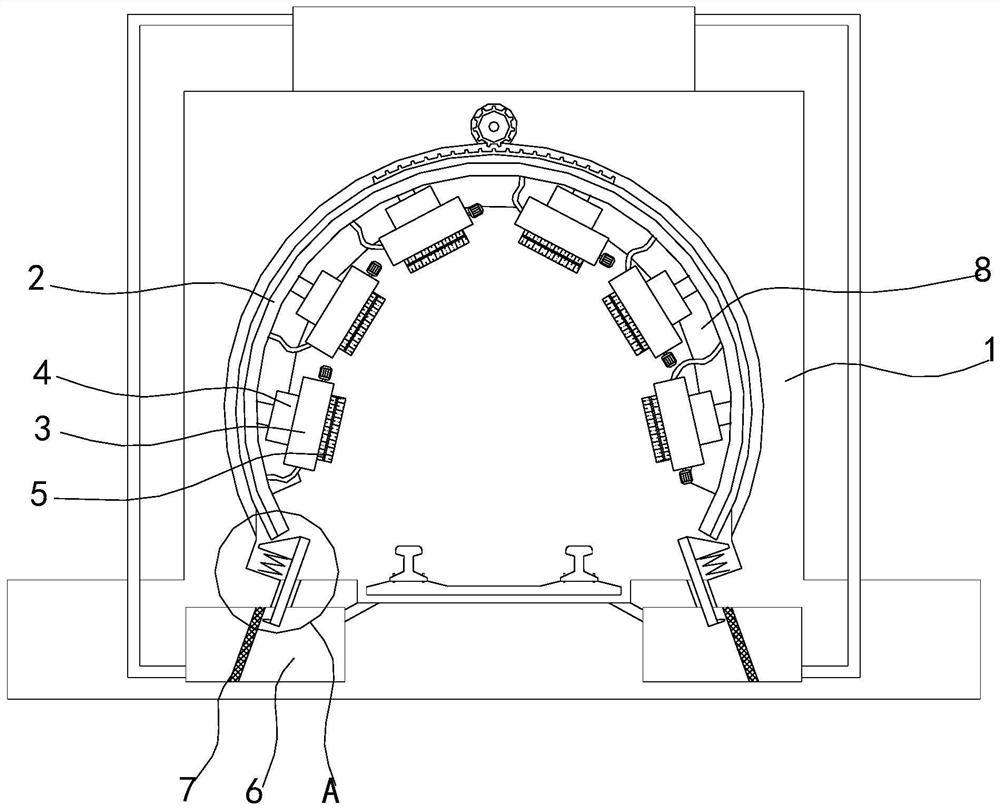

[0024] see Figures 1 to 6 , a plane structure diagram and a three-dimensional structure diagram of an environmental protection anti-scratch cleaning device for rail transit vehicles.

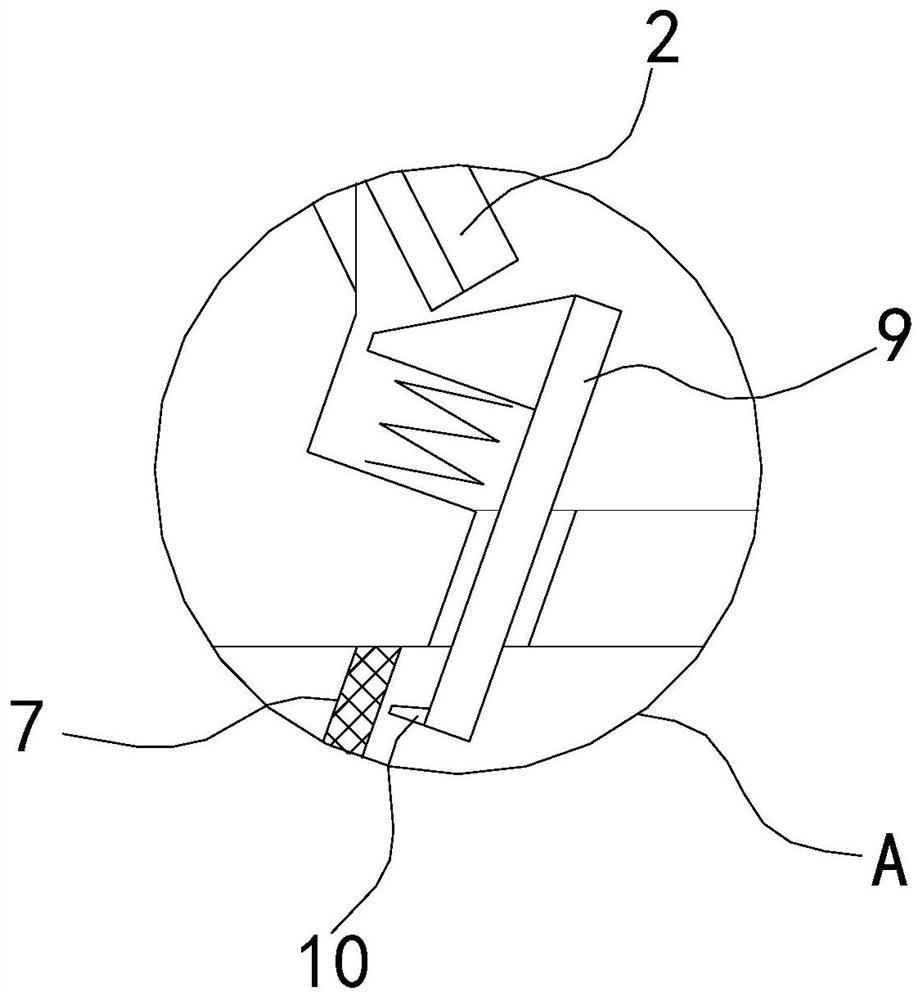

[0025] An environmental protection anti-scratch cleaning device for rail transit vehicles, comprising a device main body 1, a rotating ring 2 is movably installed on the inner wall of the device main body 1, a cleaning device 3 is fixedly installed on the rotating ring 2, and a slag blocking device 13 is movably installed inside the cleaning device 3 , A slag scraping device 9 is movably installed at the lower end inside the device main body 1 .

[0026] In specific implementation, cleaning device 3 inner side is movable to be equipped with cleaning hair brush, and the water tank that is connected with cleaning device 3 interior is fixedly installed on device main body 1 exterior, makes when cleaning hair brush 5 rotates and cleans rail vehicle, can have Water jets on the outside of the rail v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com