A high-power ultraviolet picosecond laser processing system

A processing system, high-power technology, used in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve problems such as poor material cooling effect, inconvenient transportation of overheated materials, and impact on material processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

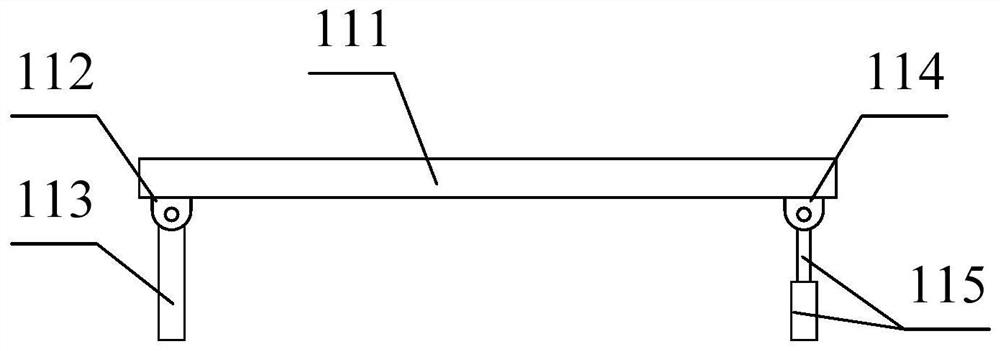

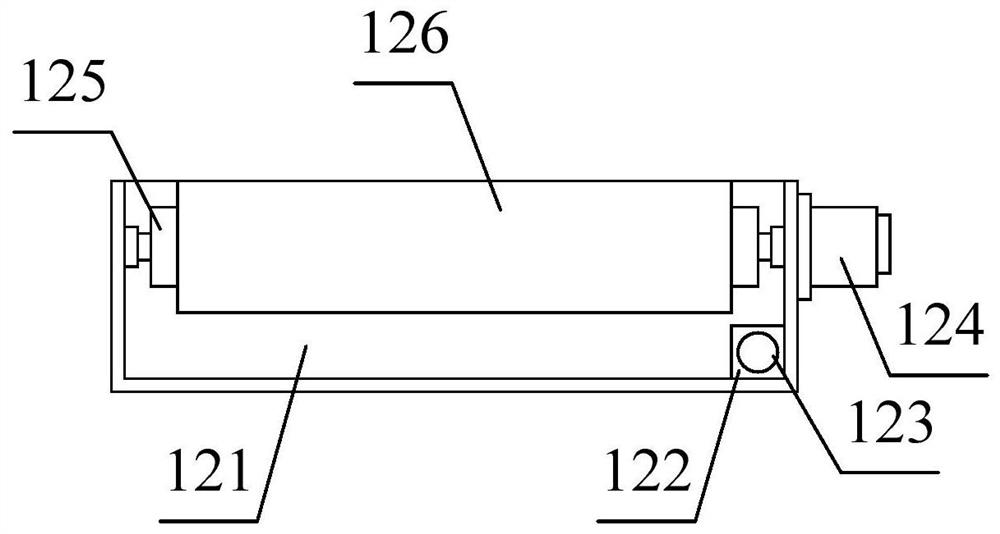

[0032] as attached figure 1 And attached figure 2 As shown, a high-power ultraviolet picosecond laser processing system according to the present invention includes a body 1, a mounting shell 2, a placement hole 3, a slide rail 4, a slide plate 5, a slide block 6, a PLC 7, a drive switch 8, Clamping cylinder 9, clamping plate 10, tiltable transport table structure 11, transportable box structure 12, water spray cooling tube frame structure 13, penetration hole 14, air outlet hole 15 and optical fiber laser puncher 16, said The mounting shell 2 bolts are installed on the upper end of the body 1; the placement hole 3 is opened on the left side of the inner wall of the mounting shell 2; the slide rail 4 is respectively bolted to the left side of the upper surface of the body 1 and the upper surface of the mounting shell 2 the left side; the slider 6 is respectively bolt-moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com