Centrifugal separation device and mixed solution separation and culture method

A technology of centrifugal separation and mixed liquid, which is applied in the direction of centrifuges, biochemical cleaning devices, biochemical equipment and methods, etc., which can solve the problems of difficult manufacturing process, high standard of production materials, and increased separation of samples from external contamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

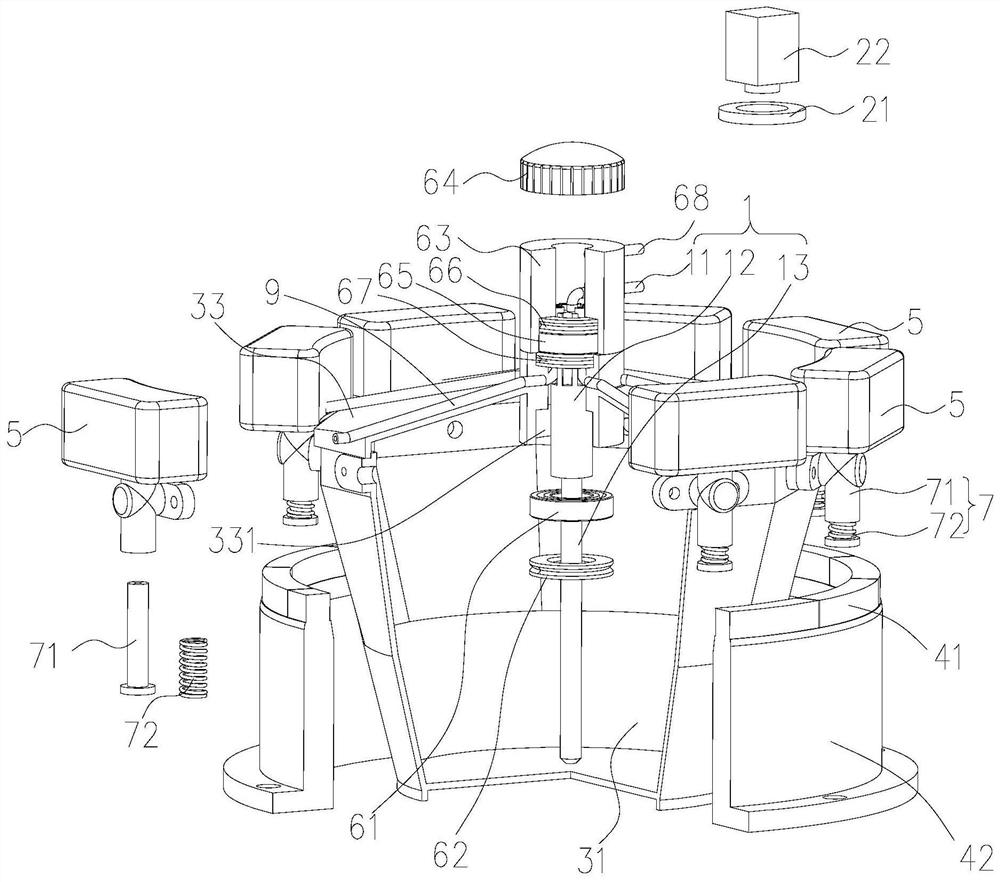

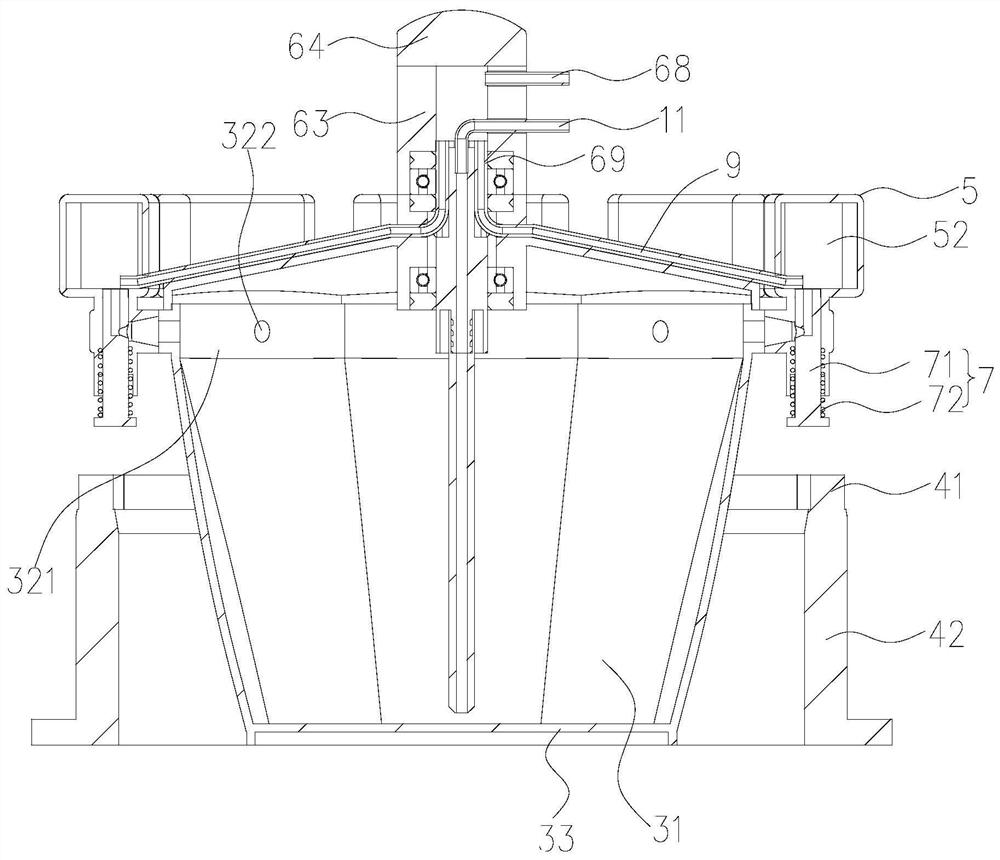

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the application with reference to the drawings in the embodiments of the application. Apparently, the described embodiments are only some of the embodiments of the application, not all of them. The embodiments listed in this application may be properly combined with each other.

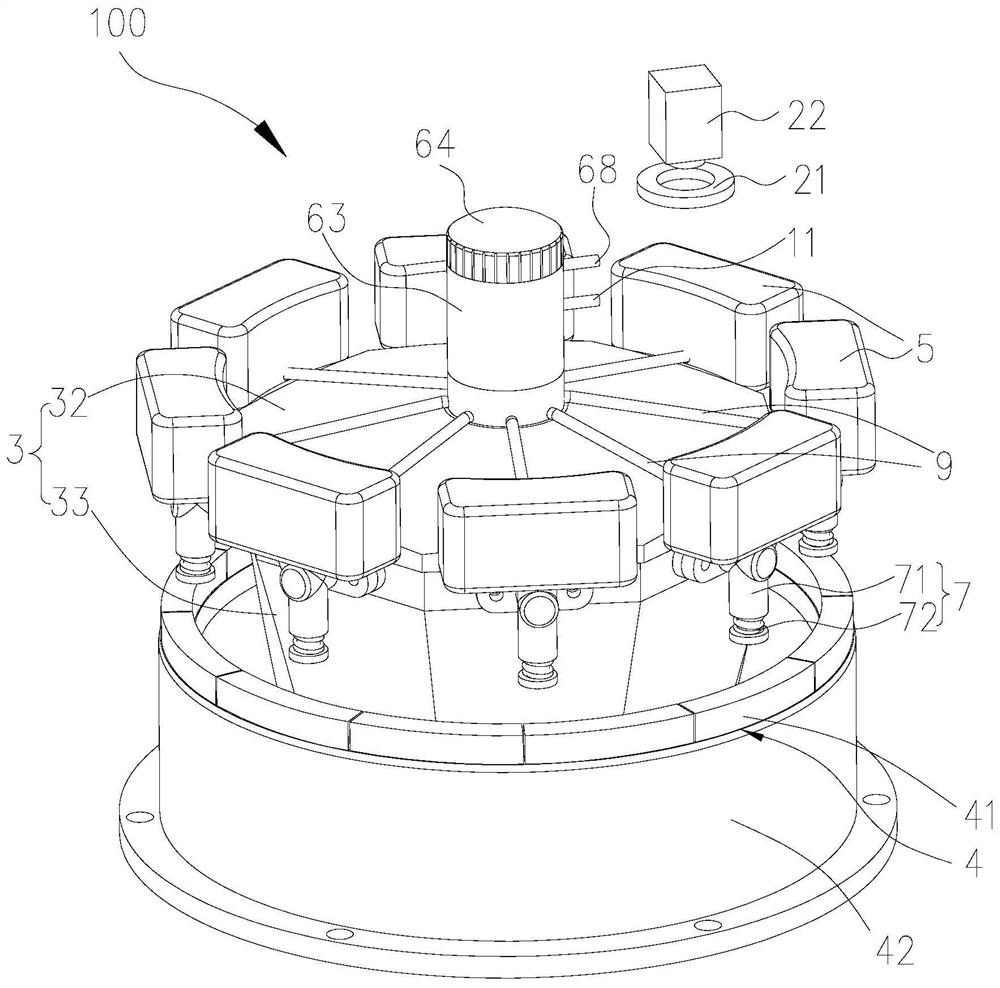

[0031] A centrifugal separation device 100 provided in an embodiment of the present application is applied to separate mixed liquids. The mixed solution includes a variety of monomer solutions with different specific gravity. The mixed solution includes but not limited to blood, cell mixed solution, various bacterial culture solutions and the like. In this application, the centrifugal separation device 100 is used as an example to illustrate the separation of blood.

[0032] Please also refer to figure 1 and figure 2 , the centrifugal separation device 100 includes at least one liquid guiding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com