Energy-saving ultra-high-power concentration membrane assembly, membrane bag thereof, water treatment system and water treatment method

A membrane module and membrane bag technology, which is applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of low concentration end point of membrane module wastewater and achieve an increase in total dissolved solids concentration , avoid short flow, reduce the head effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

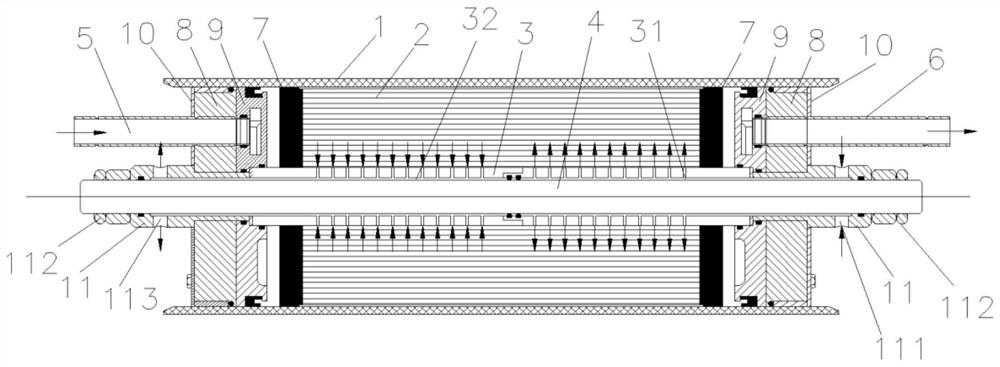

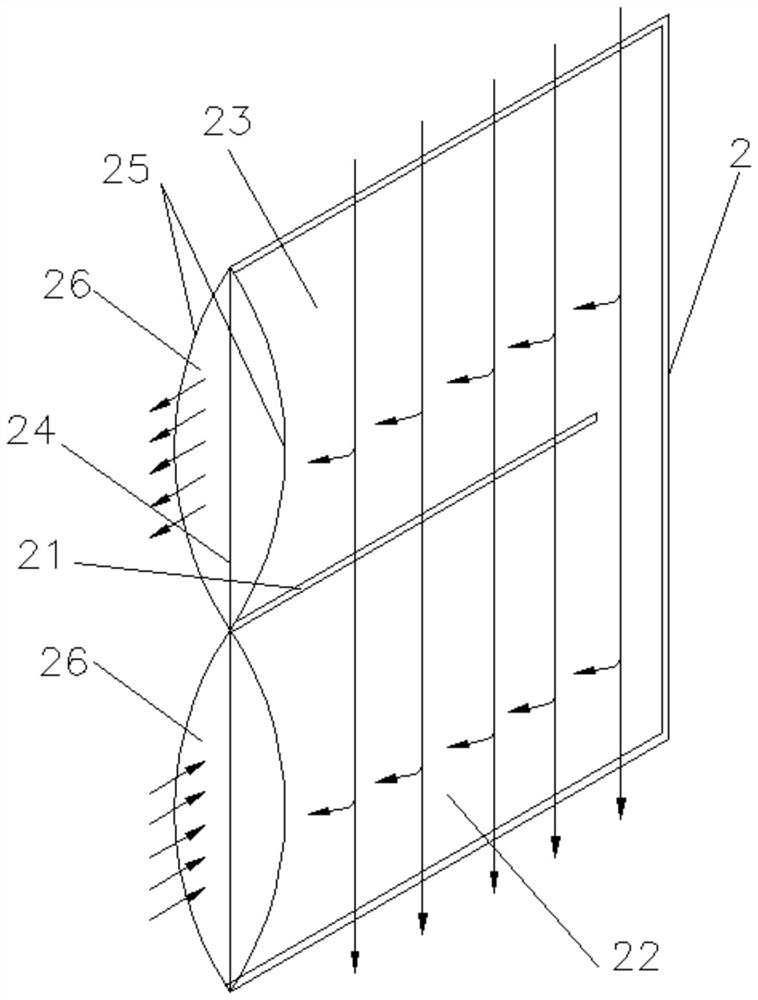

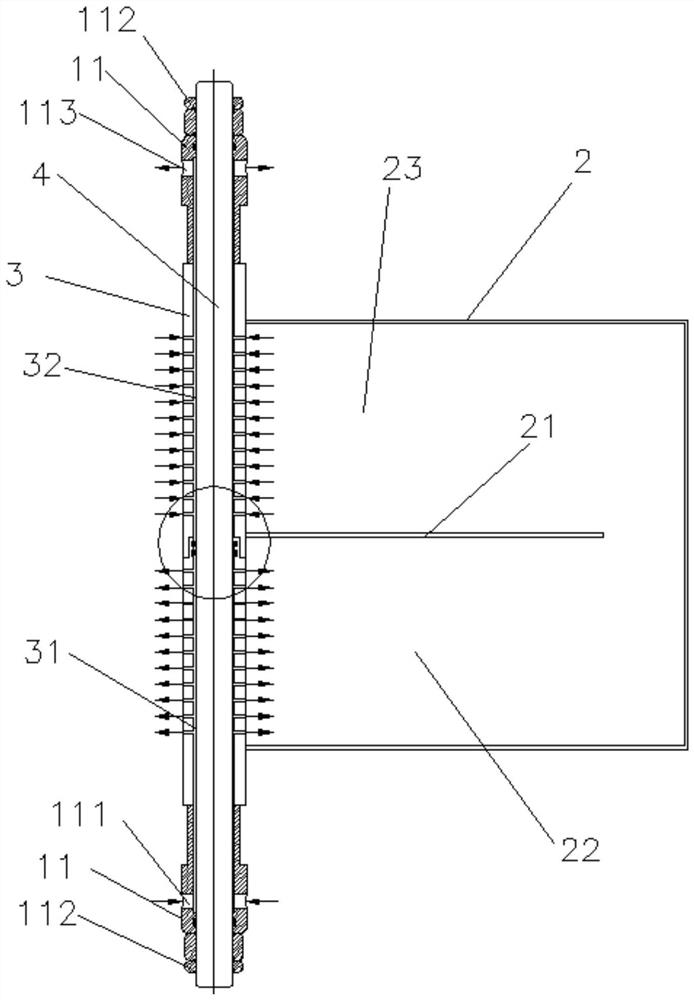

[0038] Such as Figure 1~4 As shown, an energy-saving high-power concentration membrane assembly 100 includes a membrane case 1, a water production pipe 3 and a membrane bag 2, the membrane case 1 is used to accommodate the membrane bag 2 and the water production pipe 3, and the membrane bag 2 The inner space of the membrane shell 1 is divided into the high concentration side located outside it and the water production side located in the inner space thereof, the membrane bag 2 has an open end 26, and the inner space of the membrane bag 2 is provided with a End 26 begins to extend and make the adhesive edge 21 that the inner surface of the membrane bag 2 is pasted, and the adhesive edge 21 divides the water production side into a brine injection area 22 and a mixed solution output area 23 that communicate with each other. The inner chamber of the water production pipe 3 includes a saline channel 31 and a mixed solution channel 32 that are not connected to each other, the membr...

Embodiment 2

[0048] Such as Figure 5 As shown, as another embodiment of the present invention, a water treatment system includes a common reverse osmosis module 200 (taking a traditional STRO module as an example), a circulating brine tank 300 and one of the above-mentioned membrane modules 100, the circulating brine tank 300 through the brine injection pump and the brine injection interface 111, and a pressure sensor 302 is set on the pipeline between the brine injection pump 301 and the brine injection interface 111, and the mixed solution outlet 113 is connected to the brine through the mixed solution pump 201 The raw water inlet of the ordinary reverse osmosis module 200 is connected, the concentrated water outlet of the reverse osmosis module 200 is connected to the circulating brine tank 300, and the raw water interface 5 of the membrane module 100 is connected to the water inlet pipe 51 of the liquid to be treated through the high-pressure pump 101 , the concentrated water interfac...

Embodiment 3

[0051] Such as Figure 6 As shown, as another embodiment of the present invention, in order to achieve a higher concentration factor, one membrane module 100 in the water treatment system of the above embodiment is replaced with six membrane modules 100, the first membrane module 100 The raw water interface 5 is connected to the to-be-treated liquid inlet pipe 51 through the high-pressure pump 101, the raw water interface 5 of the nth membrane module 100 is connected to the concentrated water interface 6 of the n-1th membrane module 100, Wherein n≥2, the concentrated water interface 6 of the last membrane module 100 is connected to the concentrate outlet pipe 61, and the brine injection interface 111 of each membrane module 100 is connected to the brine injection pump 301, each The mixed solution outlets 113 of each of the membrane modules 100 are connected to the raw water inlet of the reverse osmosis module 200 through the mixed solution pump 201 . Connecting multiple membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com