Method for predicting fusion width of underwater wet welding seam

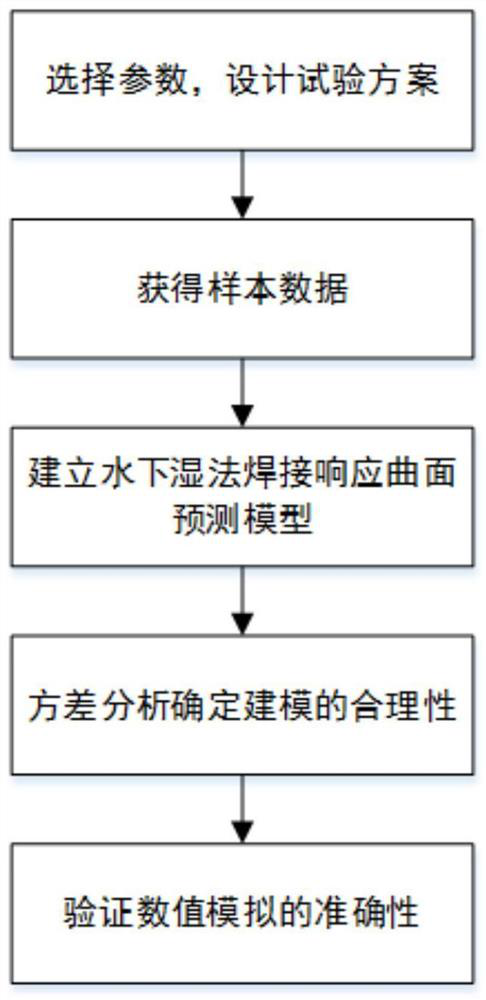

A prediction method, a technology of wet welding, applied in the field of simulation algorithm, can solve problems such as the difficulty of predicting the weld width of the welding seam, and achieve the effects of improving the welding process, saving manpower and material resources, and good welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 3: Carry out regression analysis on the sample data with the help of Design-Expert software, and establish an underwater wet welding response surface prediction model;

[0037] Using a second-order response surface model, the model can be expressed as:

[0038]

[0039] In the formula, β ij for x i and x j The interaction effect between; β ij for x i secondary effect.

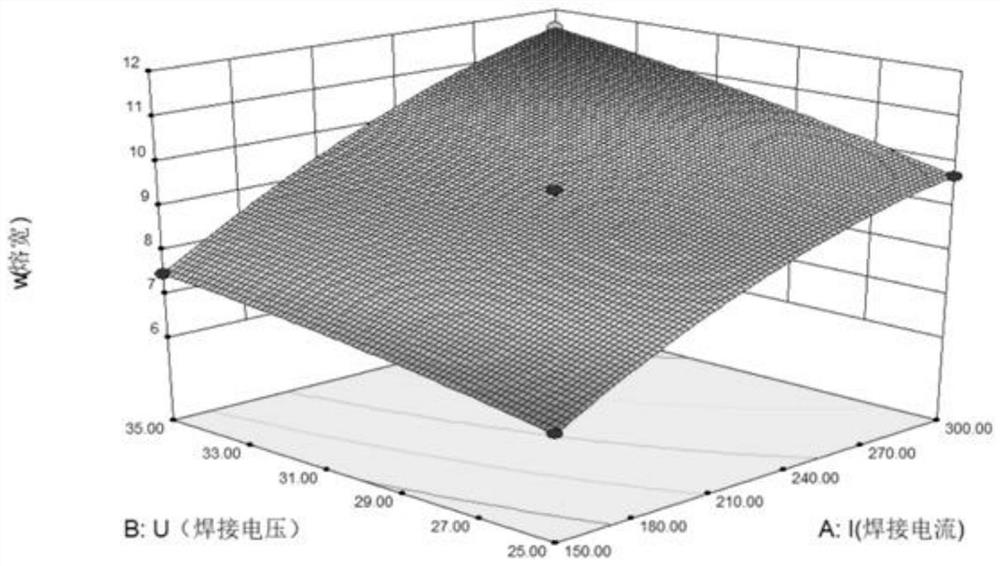

[0040] Solved from the experimental results, the final equation expressed in terms of programmed factors is:

[0041] W=9.38+1.87x 1 +0.76x 2 -0.39x 3 +0.18x 1 x 2 +0.042x 1 x 3 +0.033x 2 x 3 -0.49x 1 2 -0.13x 2 2 +0.13x a 2

[0042] Where W represents weld width, x 1 represents the welding current, x 2 represents the welding voltage, x 3 represents water depth;

[0043] The final equation derived from the above three influencing factors of underwater welding is:

[0044] W=-5.54+0.05I+0.34U-0.03h+4.80×10 -4 IU+1.88×10 -5 Ih+2.17×10 -4 Uh+8.62×10 -5 I 2 -5.00×10 -a...

Embodiment 2

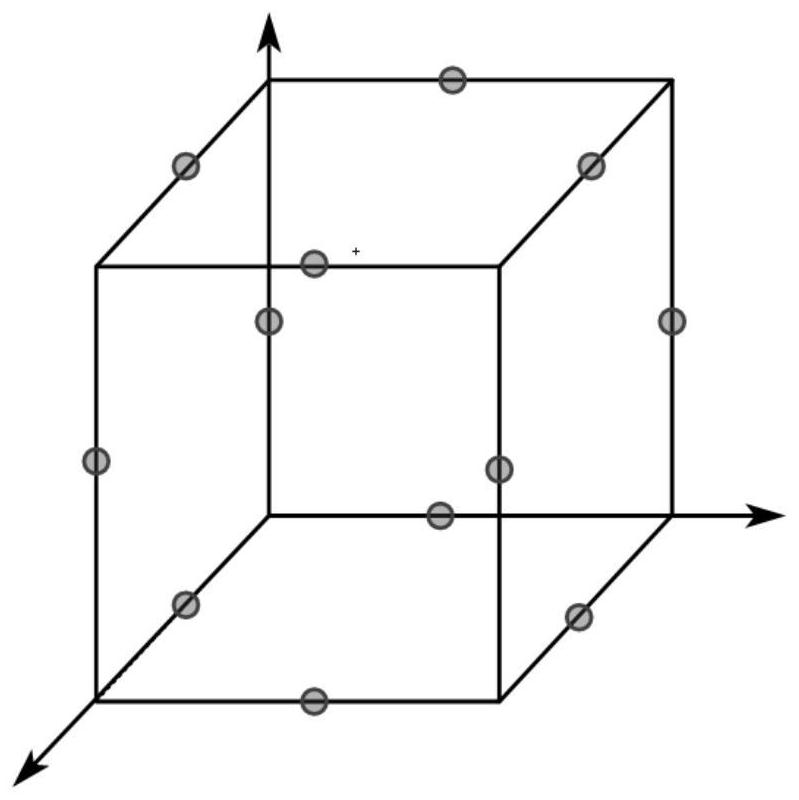

[0060] Step 3: Take the same experimental plan and experimental data, use Design-Expert software to perform regression analysis on the sample data, and call the Central Composite model;

[0061] Solved from the experimental results, the final equation expressed in terms of programmed factors is:

[0062] W=9.31+1.98x 1 +0.12x 2 -0.38x 3 +0.13x 1 x 2 +0.097x 1 x 3 +0.025x 2 x 3 -0.036x 1 2 -0.036x 2 2 +0.37x 3 2

[0063] Where W is the weld width, x 1 represents the welding current, x 2 Table welding voltage, x 3 represents water depth;

[0064] The final equation based on the above three underwater welding influence factors is:

[0065] W=-1.83036+0.041368I+0.19687U+0.026930h-3.60000×10 -4 IU-4.33333×10 - 5 Ih - 1.66667×10 -4 Uh-6.42182×10 -5 I 2 -1.44491×10 -3 u 2 -4.14627×10 -4 h 2

[0066] Where W is the weld width, I is the welding current, U is the welding voltage, and h is the water depth;

[0067] Step 4: The response surface analysis of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com