Special quality detection equipment for building bricks

A technology for testing equipment and bricks, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, conveyor objects, etc., to achieve the effect of accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

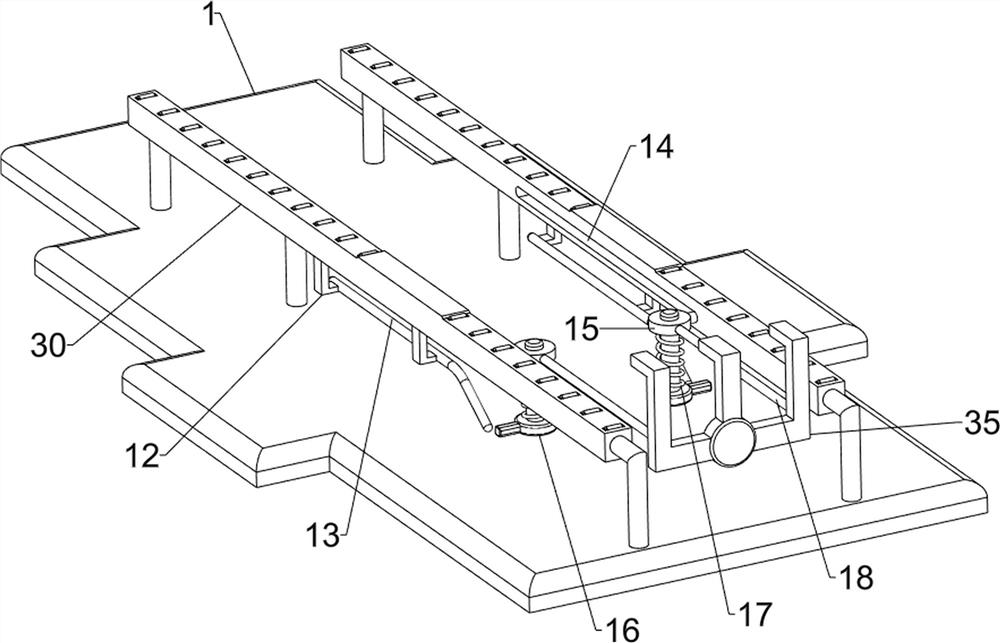

[0025] A special quality inspection equipment for building bricks, such as figure 1 As shown, it includes a base 1, an electric push rod 2, a pusher mechanism 3, a detection mechanism 4 and a blanking frame 5, an electric push rod 2 is arranged in the middle of the top of the base 1, and a pusher mechanism 3 is arranged on the front and rear sides of the top of the base 1 , the pusher mechanism 3 is connected with the electric push rod 2, the detection mechanism 4 is provided on the middle side of the top of the base 1, the detection mechanism 4 is connected with the pusher mechanism 3, the top left side of the base 1 is evenly equipped with a blanking frame 5, and the blanking frame 5 The number is 3, and the right end of the blanking rack 5 is all connected with the pushing mechanism 3.

[0026] When people need to inspect the quality of building bricks, they place the bricks on the parts of the pusher mechanism 3, and they start the electric push rod 2, and the telescopic r...

Embodiment 2

[0028] On the basis of Example 1, such as Figure 2-4 As shown, the pushing mechanism 3 includes a placement frame 30, a roller 31, a mounting block 32, a guide frame 33, a compression spring 34 and a push frame 35, and a placement frame 30 is connected between the front and rear sides of the base 1 top, and the placement frame 30 The top is evenly provided with rollers 31, and the left and right sides of the placement frame 30 are symmetrically provided with mounting blocks 32, and a guide frame 33 is slidably connected between the mounting blocks 32 on the front side and the rear side. Compression springs 34 are connected between them, and the compression springs 34 are all sleeved on the guide frame 33. A push frame 35 is connected between the right ends of the placement frame 30. The push frame 35 is connected with the parts of the detection mechanism 4, and the push frame 35 is connected with the electric push rod 2. The telescopic rod is connected.

[0029] When people ...

Embodiment 3

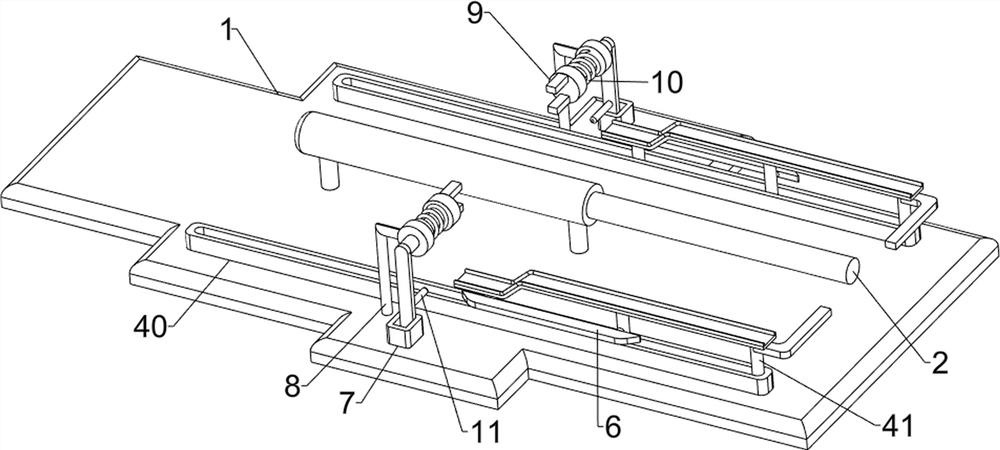

[0033] On the basis of Example 2, such as Figure 5-7 As shown, it also includes a wedge plate 6, a guide rail 7, a third sliding sleeve 8, a locking rod 9, a first spring 10 and a contact rod 11. The lower side of the sliding frame 41 is symmetrically provided with a wedge plate 6, and the top of the base 1 The middle side is symmetrically provided with a guide rail 7, and the guide rail 7 is located on the left side of the first sliding sleeve 43, and the middle side of the top of the base 1 is symmetrically provided with a third sliding sleeve 8, and the third sliding sleeve 8 is located on the left side of the guide rail 7 , the right part of the third sliding sleeve 8 is symmetrically slidably connected with a clamping rod 9, the clamping rod 9 is slidingly connected with the guide rail 7, and the first spring 10 is connected between the clamping rod 9 and the third sliding sleeve 8 , the first springs 10 are both sleeved on the clamping rod 9, and the lower side of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com