Solid web type horizontal steel beam high-altitude installation temporary fixing structure and implementation method

A technology of temporary fixation and implementation method, applied in truss-type structures, joists, girders, etc., can solve the problems of reduced work efficiency, increased construction cost, and large construction workload, and can prevent front and rear deviation, prevent left and right deviation, Guaranteed installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

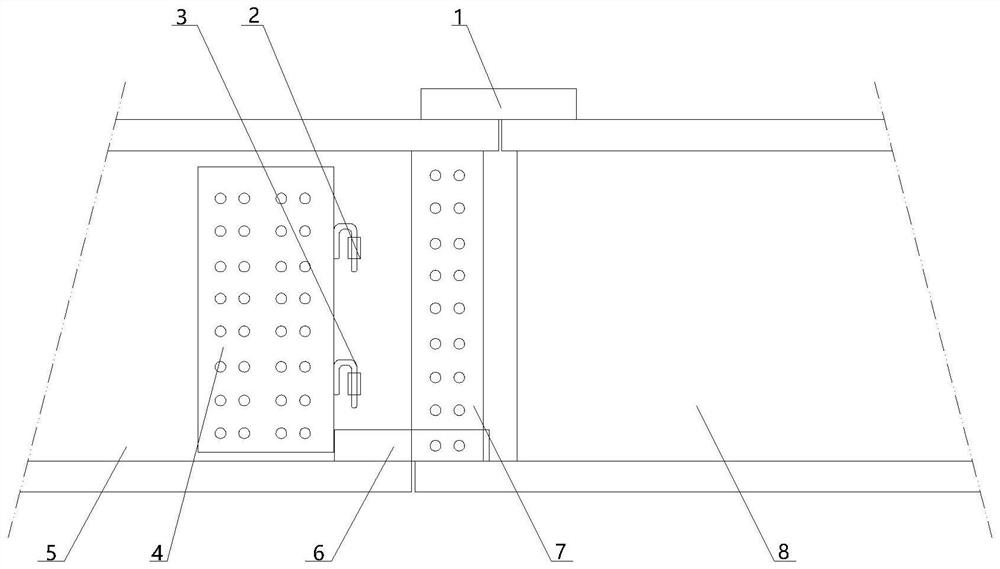

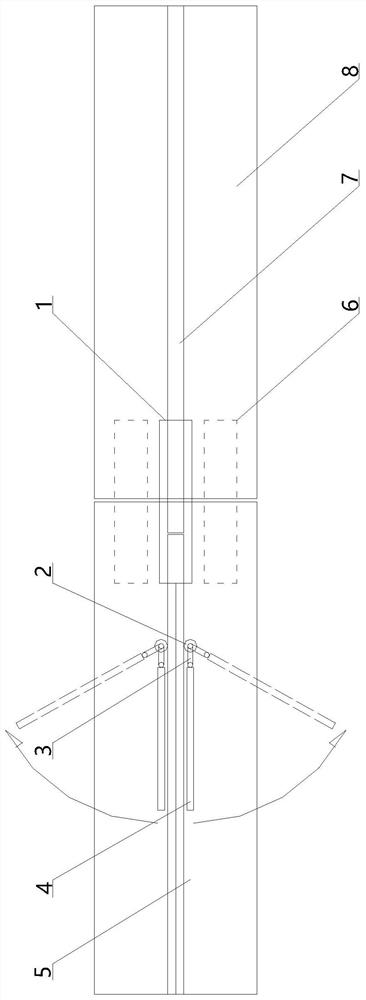

[0027] refer to Figure 1 to Figure 2 As shown, a temporary fixed structure of solid-web horizontal steel beams installed at high altitude, including 1# solid-web horizontal steel beams 5 and 2# solid-web horizontal steel beams 8, and the upper wing of 1# solid-web horizontal steel beams 5 The edge protrudes toward the side of 2# solid-web horizontal steel beam 8 relative to the lower flange, and the lower flange of 2# solid-web horizontal steel beam 8 is opposite to the upper flange of 1# solid-web horizontal steel beam #Solid-belly horizontal steel beam 5 protrudes near one side, and the protruding length is equal to the protruding length of the upper flange of 1# solid-web horizontal steel beam 5, so as to achieve complete fit and ensure the flatness and connection after connection quality. The upper surface of the upper flange of 1# solid-web horizontal steel beam 5 is fixedly connected with an upper flange ridge stopper 1 (the upper flange ridge stopper 1 and the web 7 o...

Embodiment approach

[0032] An implementation method for installing a temporary fixed structure of a solid-web horizontal steel beam at high altitude, comprising the following steps:

[0033] 1) Make connection hook 3, hook cover 2:

[0034] The hook cover 2 is a Φ12mm steel pipe, and the connecting hook 3 is a "U" piece made of Φ10mm round steel;

[0035] Two), install the connection hook 3, the hook cover 2, and the connection plate 4:

[0036] The hook cover 2 is welded and fixed on the web 7 of the beam, the connecting hook 3 is welded and fixed on the connecting plate 4, and the connecting hook 3 is inserted into the hook cover 2;

[0037] 3) Welding and installing upper flange ridge block 1 and lower flange wing block 6:

[0038] Weld the upper flange ridge stopper 1 on the upper flange surface of the 1# solid web horizontal steel beam 5 and the web 7 line, and the upper flange ridge stopper 1 is length*width*thickness 100mm*20mm*20mm ; On the lower flange plate surface of 1# solid web ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com