Yarn pressing device for covered yarn and using method thereof

A technology of covering yarn and pressing yarn, which is applied in the direction of liquid/gas/steam yarn/filament treatment, textile material carrier treatment, etc. It can solve the problems of uneven dyeing, reduce dyeing amount, and uneven strength, and achieve dyeing uniformity High, ensure safety, reduce damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

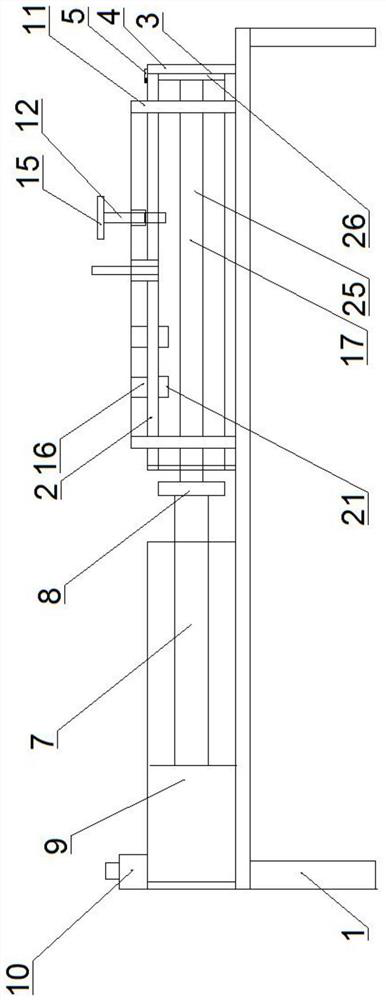

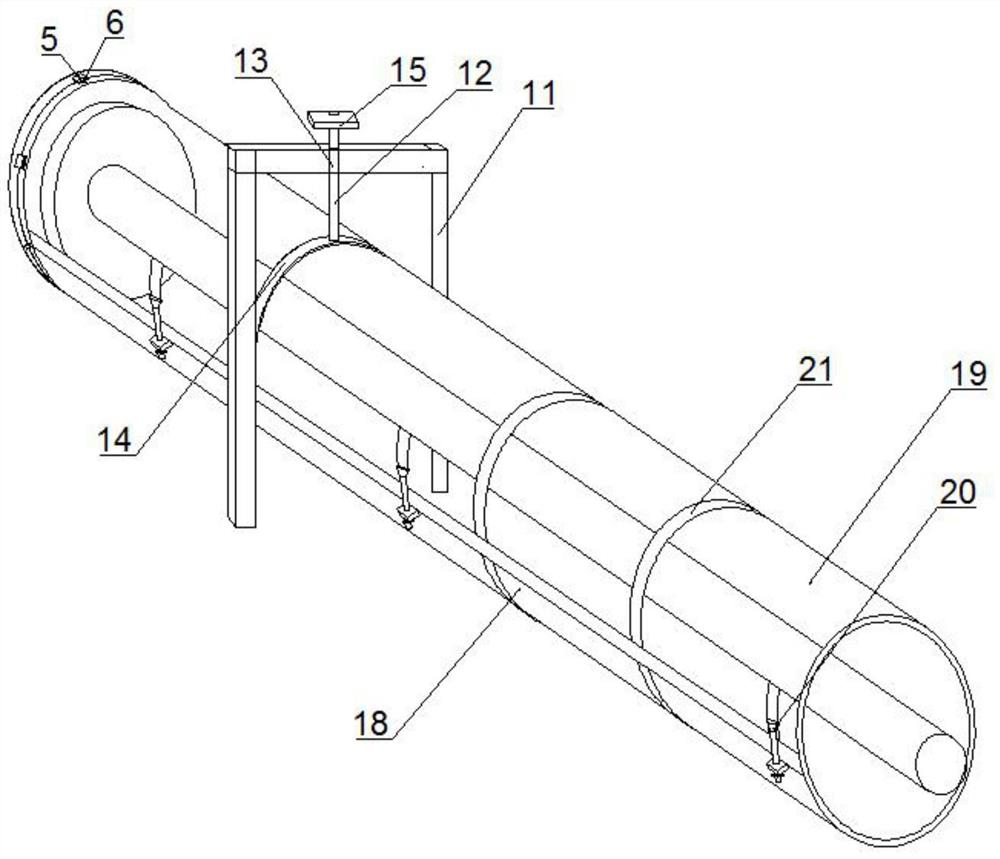

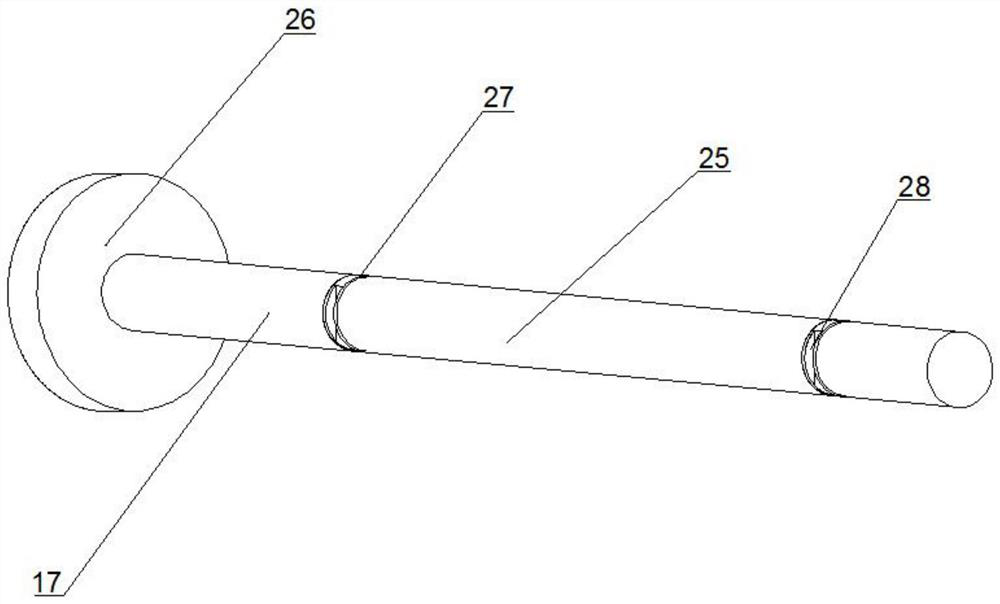

[0030]A yarn pressing device for covering yarn, comprising a yarn pressing frame 1, a yarn pressing device is installed on the yarn pressing frame 1, the yarn pressing device includes a yarn pressing drum 2, and one side of the yarn pressing drum 2 is installed There is a yarn outlet 3, and a yarn pressing baffle 4 is arranged at the yarn outlet 3, and a plurality of fixing sleeves 5 are arranged around the yarn pressing baffle 4, and the fixing sleeves 5 are movably connected with a fixed valve 6, One side of the fixed valve 6 is fixedly connected to one side of the yarn pressing cylinder 2, and the other side of the yarn pressing cylinder 2 is provided with a pushing device, and the pushing device includes a pushing rod 7, and the pushing A pusher plate 8 is installed at the front end of the rod 7, and a cylinder 9 is arranged at the rear end of the pushing rod 7, and an electromagnetic valve body 10 is installed on one side of the cylinder 9, and a yarn fixing device is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com