A liquid cosmetic canning system and method

A technology of cosmetics and canning, which is applied in the field of liquid cosmetics canning system, which can solve the problems of slow filling speed and low continuity of canning, and achieve the effect of fast filling speed and high continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

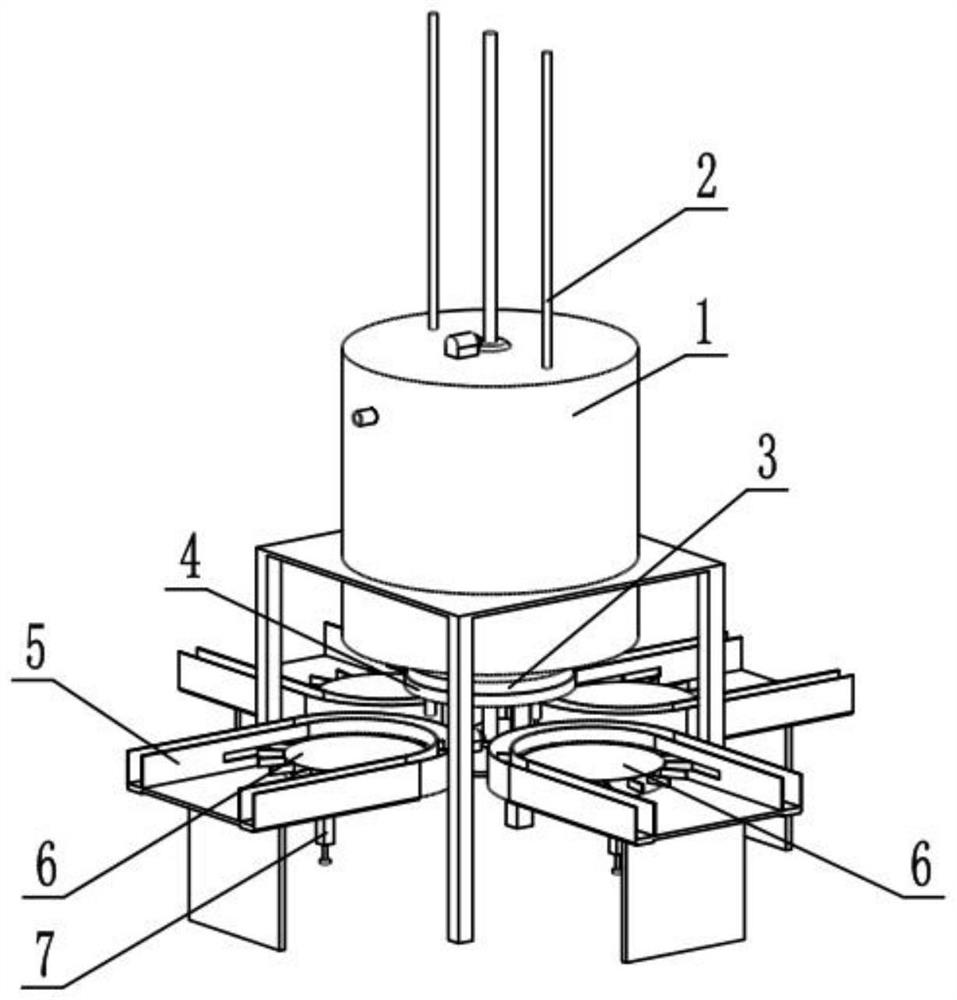

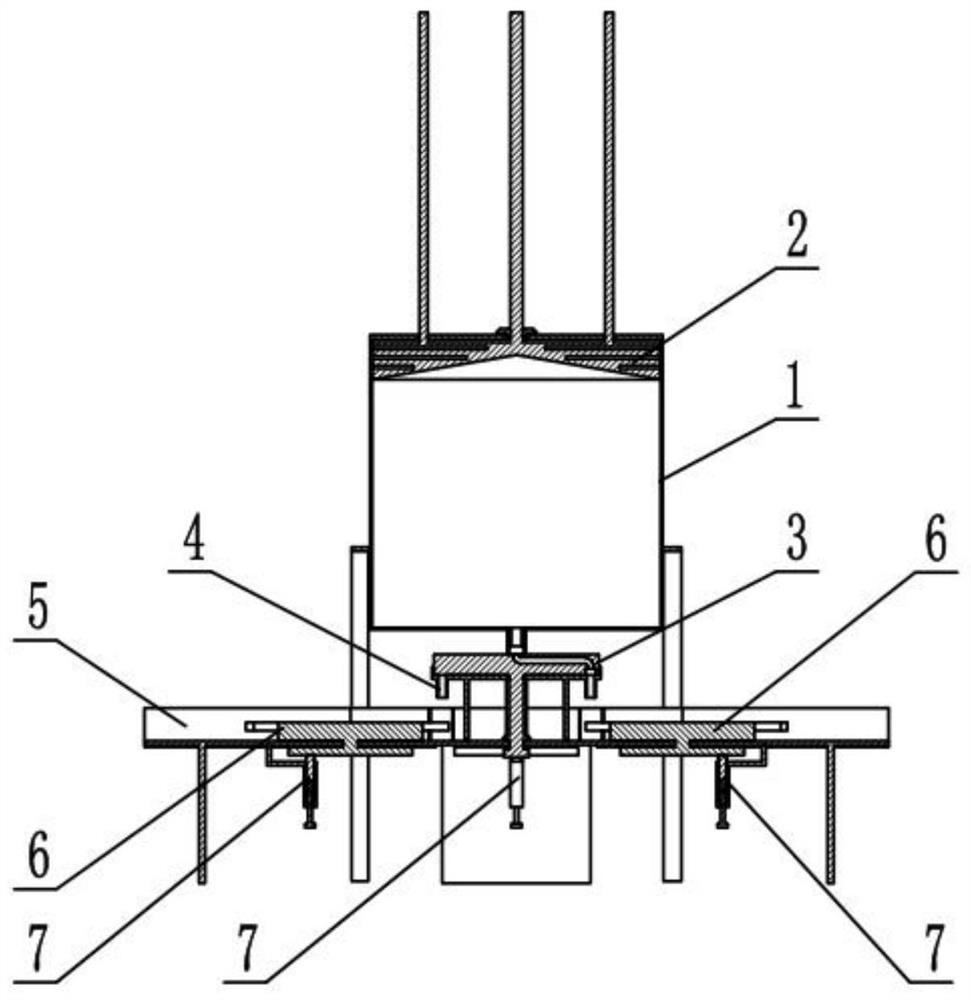

[0036] Such as Figure 1-13 As shown, a liquid cosmetic canning system includes a barrel rack 1, an extruding mechanism 2, a rotating liquid outlet mechanism 3, a filling tube rack 4, a bottle conveying bracket 5, a bottle conveying mechanism 6 and a top-tight brake Mechanism 7, the extruding mechanism 2 is slidingly connected in the barrel frame 1, the rotating liquid outlet mechanism 3 is rotatably connected to the lower end of the barrel frame 1, and the bottle delivery bracket 5 is located on the barrel frame 1 directly below, the filling pipe frame 4 is fixedly connected to the bottle conveying bracket 5, the filling pipe frame 4 is rotationally connected with the rotating liquid outlet mechanism 3, and the described bottle conveying mechanism 6 is provided with four, four Each bottle delivery mechanism 6 is rotatably connected to the bottle delivery support 5, and the four bottle delivery mechanisms 6 are meshed and transmission connected with the rotating liquid outlet ...

specific Embodiment approach 2

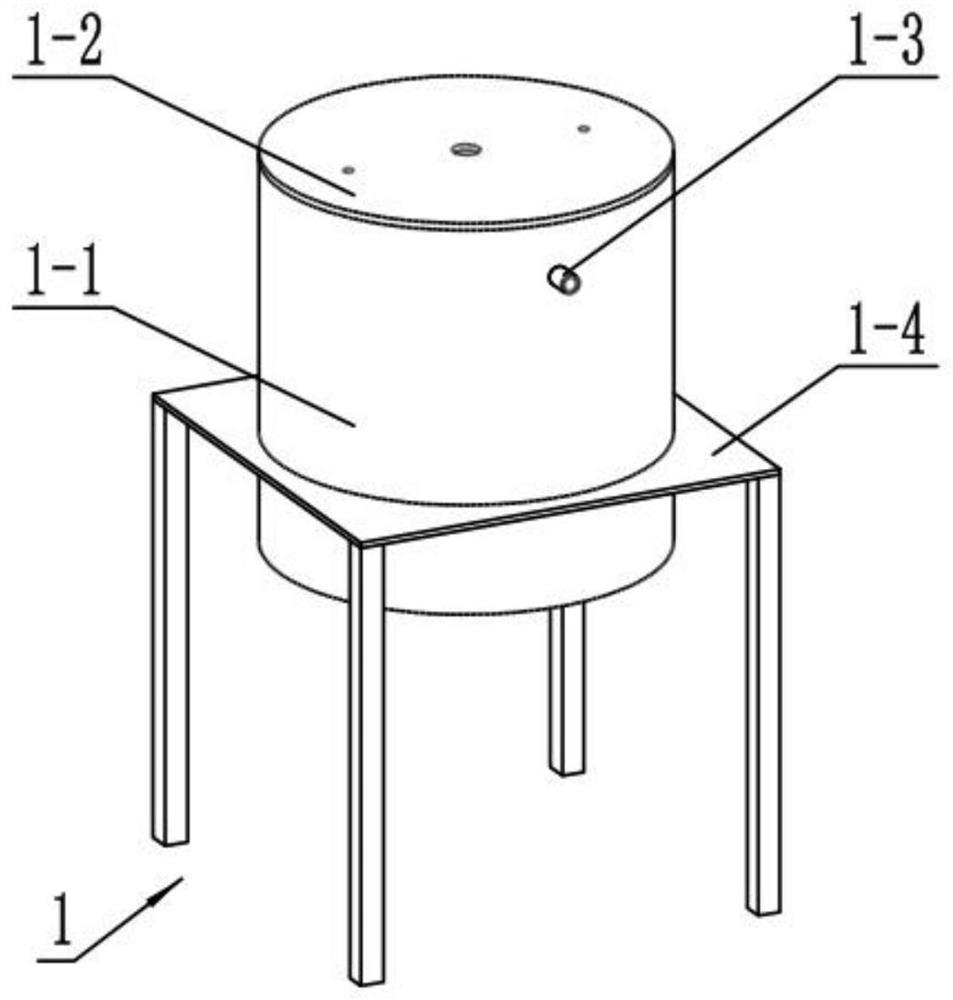

[0038] Such as Figure 1-13 As shown, the described barrel stand 1 includes a barrel 1-1, a cover plate 1-2, a liquid filling pipe 1-3, a support frame 1-4 and a drain pipe 1-5, and the barrel 1-1 is fixedly connected On the support frame 1-4, the cover plate 1-2 is fixedly connected on the container barrel 1-1, the top of the side end of the container container 1-1 is provided with a liquid feeding pipe 1-3, and the liquid discharge pipe 1-5 is fixedly connected to the container container 1-1. The lower end of the barrel 1-1 is coaxial with the barrel 1-1.

[0039] Add cosmetics into the container 1-1 through the liquid feeding pipe 1-3, and discharge the cosmetics in the container 1-1 through the liquid discharge pipe 1-5.

specific Embodiment approach 3

[0040] Such as Figure 1-13 As shown, the extrusion mechanism 2 includes a lifting plate 2-1, a sliding column 2-2, a threaded rod 2-3, a lifting motor 2-4, an internally threaded gear 2-5 and a rubber piston 2-6, and the lifting plate The lower end surface of 2-1 is fixedly connected with rubber piston 2-6, and the upper end surface of lifting plate 2-1 is fixedly connected with threaded rod 2-3 and two sliding posts 2-2, and threaded rod 2-3 is connected with rubber piston 2-2. 6 coaxial, the threaded rod 2-3 is threadedly connected with an internally threaded gear 2-5, the lifting plate 2-1 and the rubber piston 2-6 are all slidably connected with the inner wall of the container 1-1, and the two sliding columns 2-2 Slidingly connected with the cover plate 1-2, the internally threaded gear 2-5 is rotatably connected to the cover plate 1-2, and the lifting motor 2-4 is fixedly connected to the cover plate 1-2 and is transmission-connected with the internally threaded gear 2-5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com