Portable glass can capping machine

A glass jar and capping machine technology, applied to screw caps and other directions, can solve the problems of increasing the workload of operators, the inability of the cap and the bottle body to be in a parallel state, and the shaking of the cap, so as to improve the sealing effect of capping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

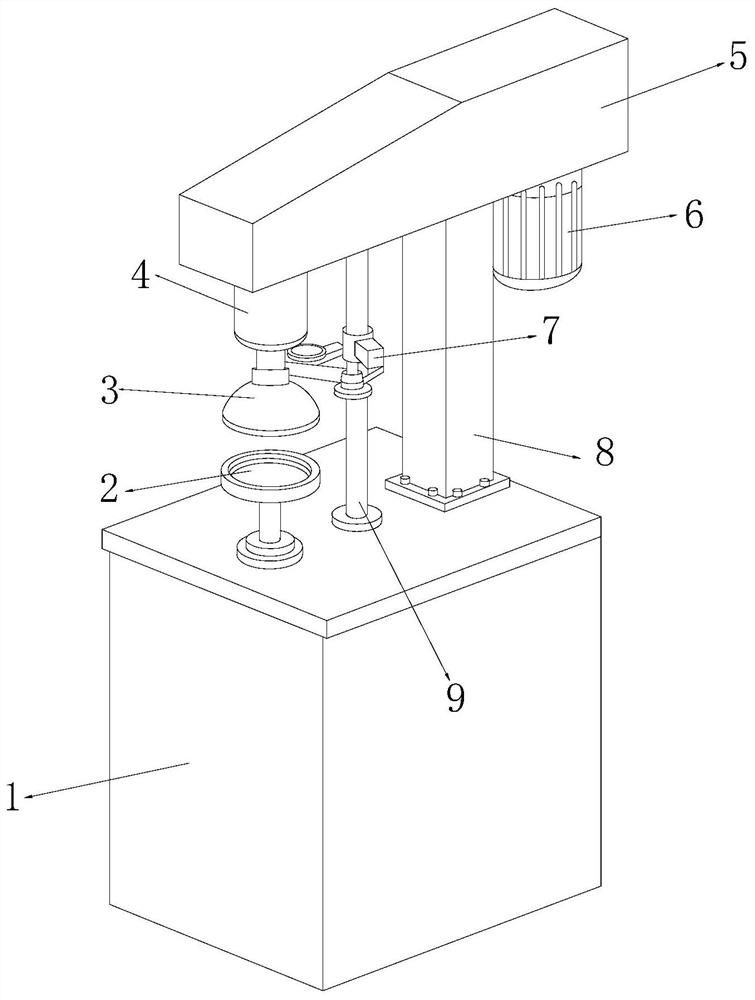

[0032] see figure 1 , the present invention provides a technical solution: a portable glass jar capping machine, the structure of which includes a body 1, a placement seat 2, a protection device 3, a rotating head 4, a mounting part 5, a motor 6, a positioning fastener 7, and a support column 8. Connecting rod 9. Placement seat 2, support column 8, and connecting rod 9 are installed on the top of the body 1. Placement seat 2, support column 8 and connecting rod 9 form the same straight line with each other, and the placement seat 2 is vertically fitted On the body 1, the support column 8 and the connecting rod 9 are fixed on the body 1 through screw locking, the support column 8 and the connecting rod 9 are connected through the mounting part 5, and the bottom end of the mounting part 5 is provided with a motor 6. The motor 6 is electrically connected to the inside of the body 1 through wires, the motor 6 and the rotary head 4 are arranged on the same module, the two sides of...

Embodiment 2

[0042] see figure 1 , the present invention provides a technical solution: a portable glass jar capping machine, the structure of which includes a body 1, a placement seat 2, a protection device 3, a rotating head 4, a mounting part 5, a motor 6, a positioning fastener 7, and a support column 8. Connecting rod 9. Placement seat 2, support column 8, and connecting rod 9 are installed on the top of the body 1. Placement seat 2, support column 8 and connecting rod 9 form the same straight line with each other, and the placement seat 2 is vertically fitted On the body 1, the support column 8 and the connecting rod 9 are fixed on the body 1 through screw locking, the support column 8 and the connecting rod 9 are connected through the mounting part 5, and the bottom end of the mounting part 5 is provided with a motor 6. The motor 6 is electrically connected to the inside of the body 1 through wires, the motor 6 and the rotary head 4 are arranged on the same module, the two sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com