Heating furnace isolation device and heating furnace conveying device

A technology for isolating devices and conveying equipment, applied in lighting and heating equipment, furnace control devices, conveyor objects, etc., can solve problems such as product recalls, affecting the quality of processed workpieces, and affecting other applications in the next process, so as to improve the quality of feed materials. The degree of control and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

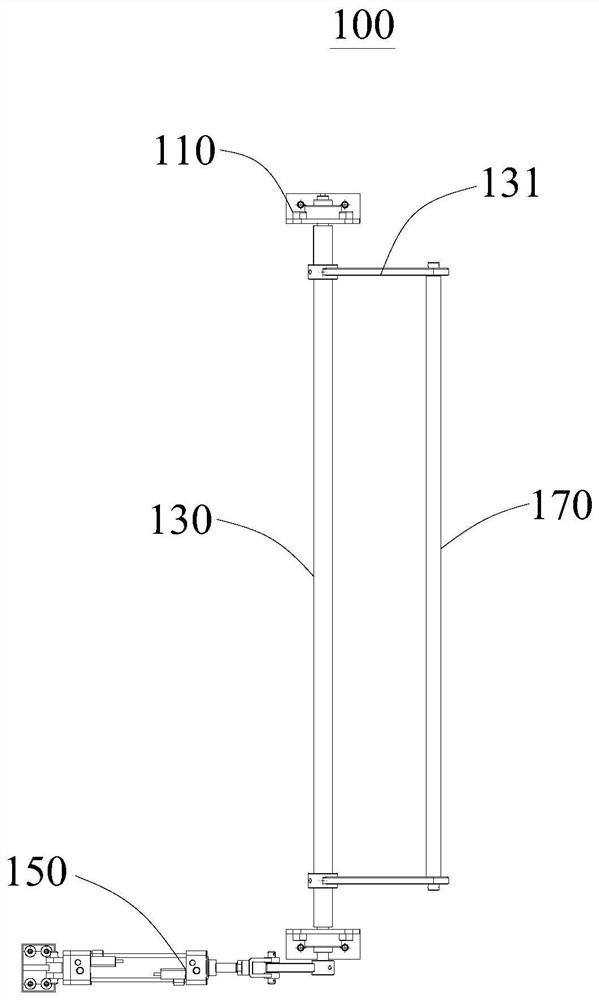

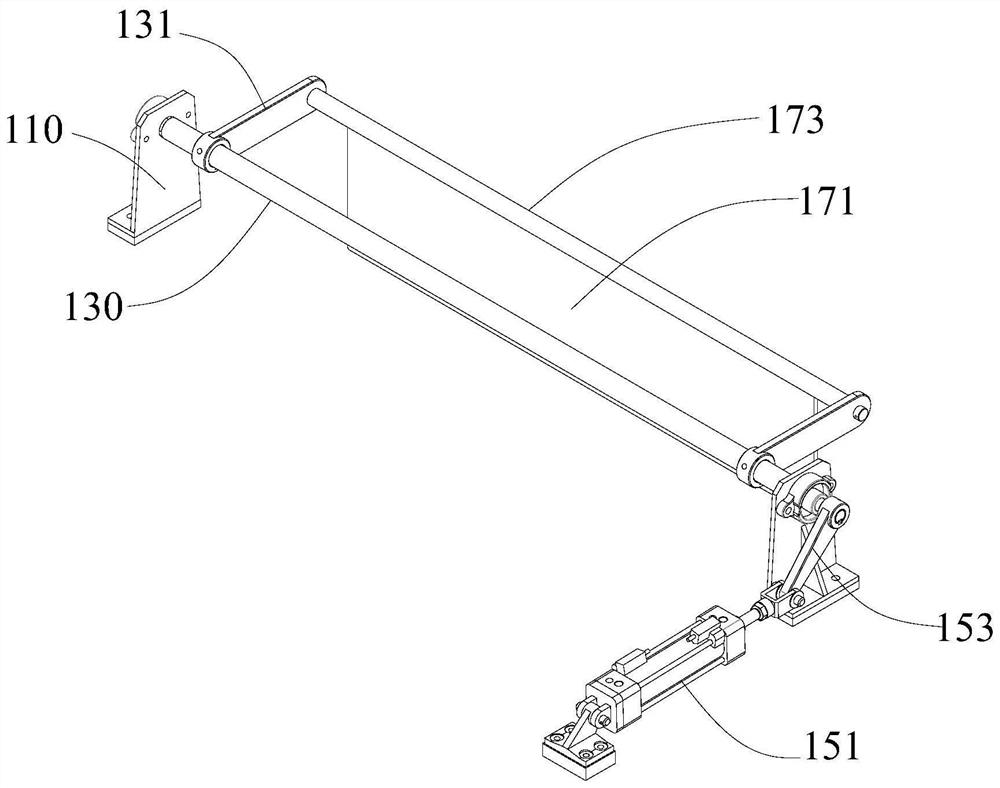

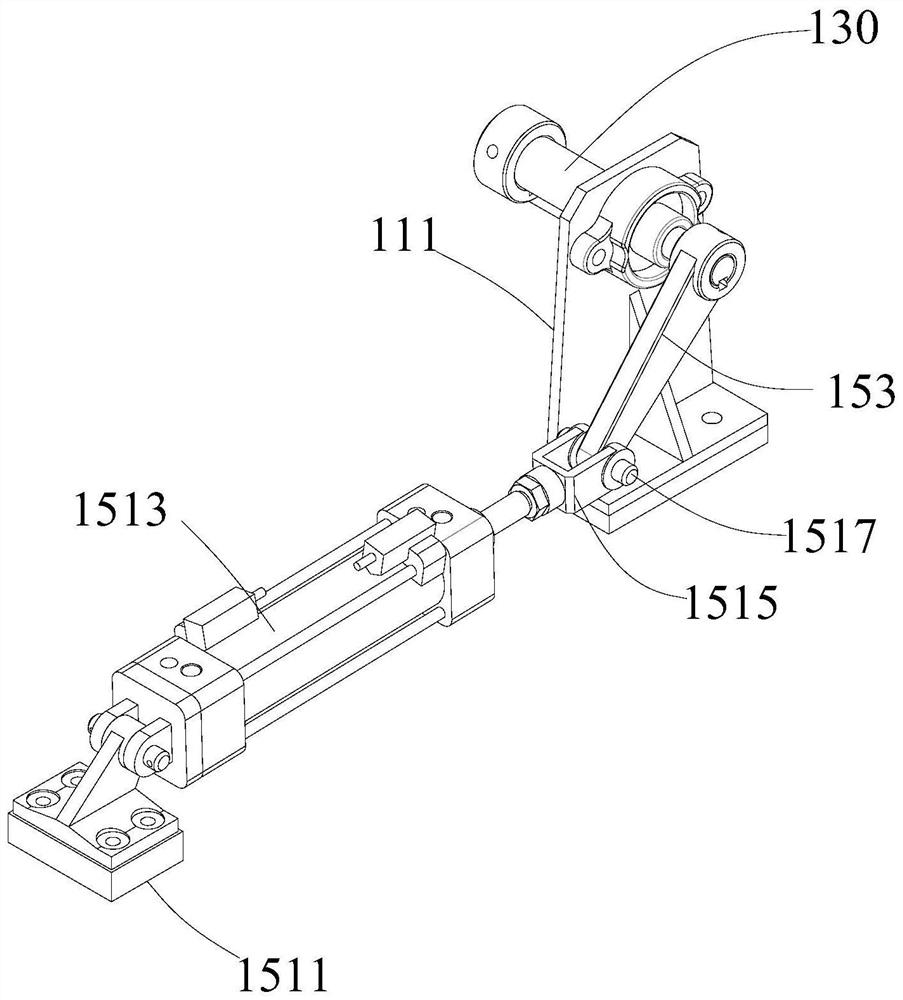

[0034] join in Figure 1 to Figure 4 , the present embodiment provides a heating furnace isolation device 100, which is used to be installed on the conveying mesh belt, which can prevent workpieces on the conveying mesh belt from directly rolling into the mesh belt heating furnace, thereby improving the degree of control over workpiece feeding and improving Handle the quality of workpieces to avoid affecting subsequent processes.

[0035] The heating furnace isolation device 100 provided in this embodiment includes a mounting frame 110, a transmission rotating shaft 130, a driving mechanism 150 and a material blocking plate 170. The mounting frame 110 is used to be installed on the conveyor belt, and the transmission rotating shaft 130 is rotatably arranged. On the mounting frame 110, and used to be placed horizontally above the conveying mesh belt, the driving mechanism 150 is in transmission connection with the transmission rotation shaft 130, and is used to drive the transm...

no. 2 example

[0057] join Figure 5 , the present embodiment provides a heating furnace conveying equipment 200, including a feed rack 210 and a heating furnace isolating device 100, wherein the basic structure, principle and technical effect of the heating furnace isolating device 100 are the same as those of the first embodiment, for brief For the description, for parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

[0058] In this embodiment, the heating furnace isolation device 100 includes a mounting frame 110, a transmission rotating shaft 130, a driving mechanism 150, and a material baffle plate 170. The driving rotating shaft 130 is rotatably arranged on the mounting frame 110, and the driving mechanism 150 rotates with the transmission. Axle 130 transmission connection is used to drive transmission rotation shaft 130 to rotate, and material retaining plate 170 is transmission connection with transmission rotation shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com