Efficient coal charging mechanism

A coal-loading, high-efficiency technology, applied in packaging, conveyors, loading/unloading, etc., can solve the problems of hill-shaped, labor-intensive, and inconvenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

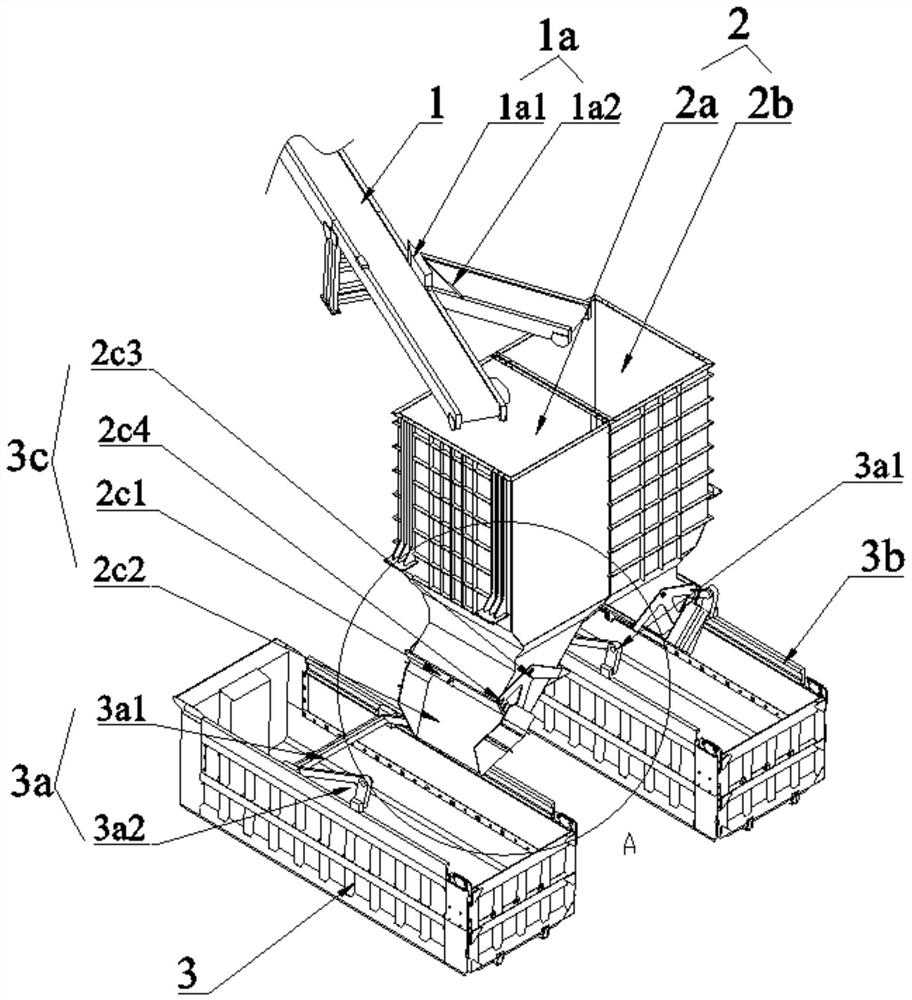

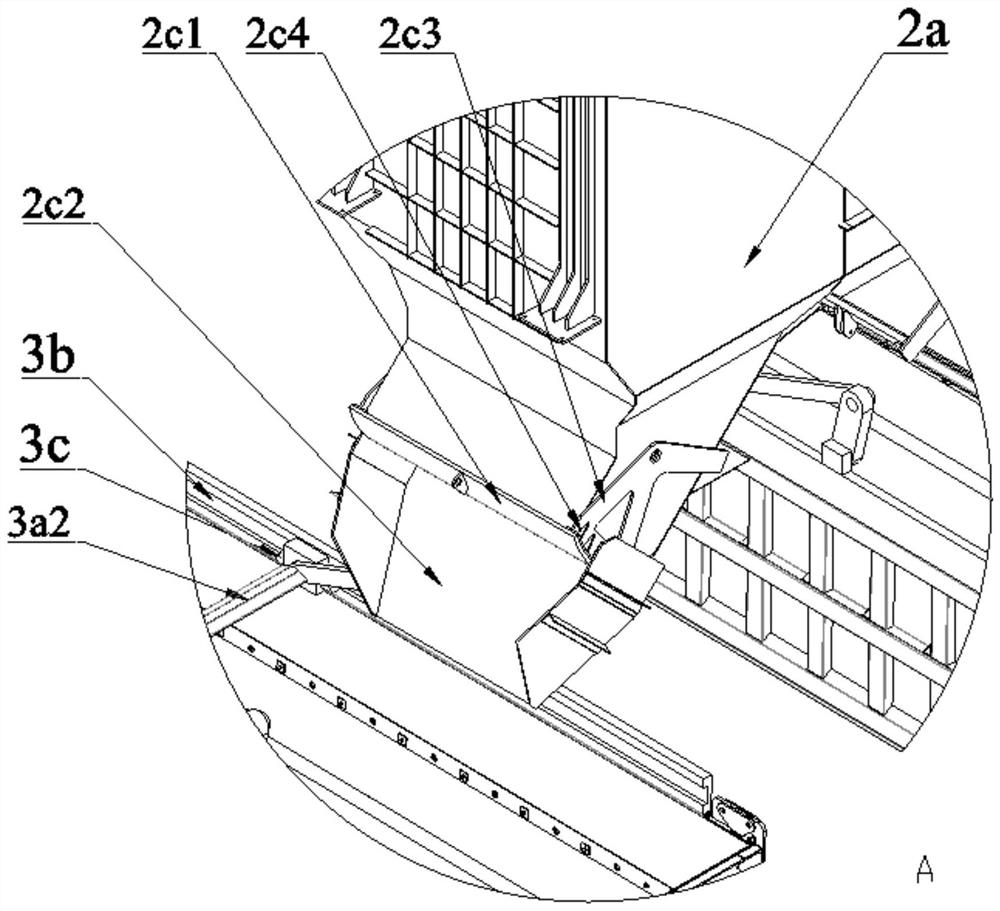

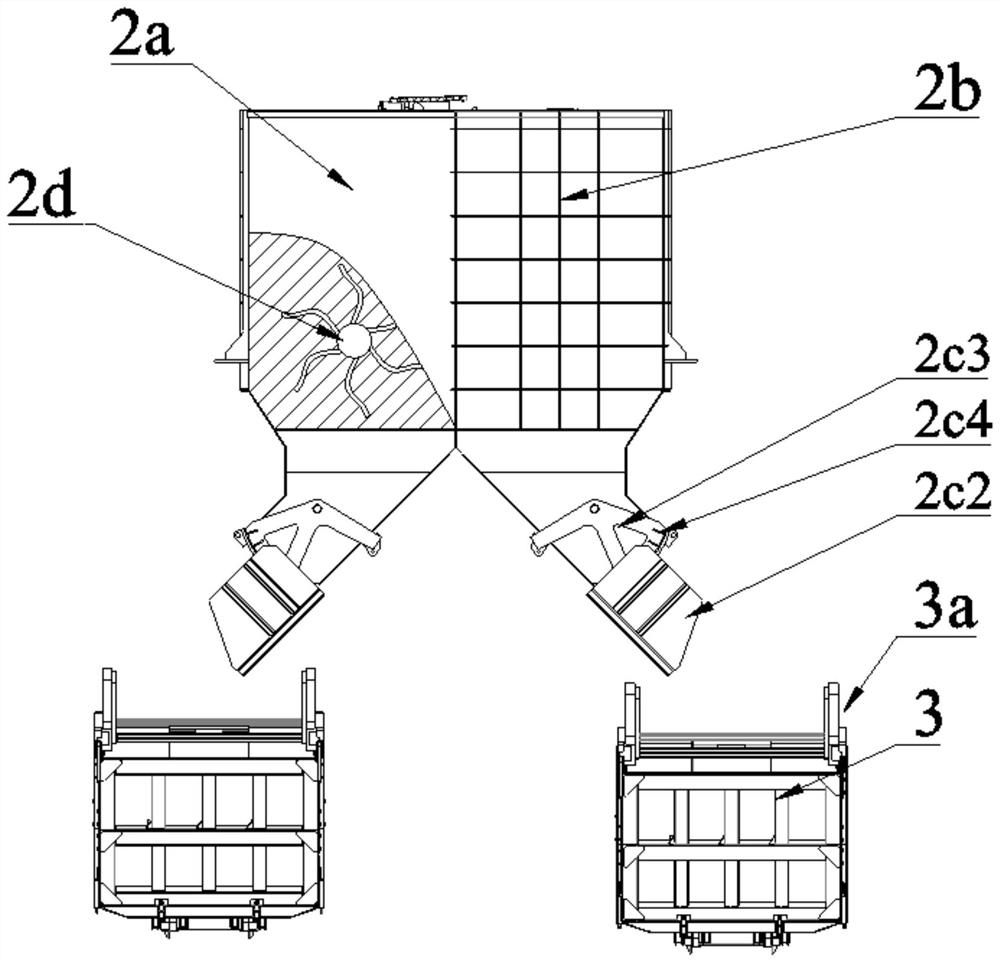

[0030] Taking the material compartment 3 to be loaded with anthracite as an example, when there are many loaded vehicles, two material compartments 3 can be used to stop at the lower ends of the first collecting bin 2a and the second collecting bin 2b respectively, and the two conveyor belts 1 start working at the same time. The anthracite is directly transported to the first collection bin 2a and the second collection bin 2b respectively, and the flow rate of the material is controlled by controlling the discharge limit mechanism 2c at the lower end of the collection bin 2 .

[0031] When the material compartment 3 is loaded with anthracite and the subsequent vehicles need to load peat, the conveyor belt 1 continues to work. If the material compartment 3 of the transport vehicle stops at the lower end of the second collecting bin 2b, the angle of the distribution plate 1a1 is adjusted by controlling the hydraulic lever 1a2 , so that the peat is transported to the second collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com