Garbage sorting and releasing device

A garbage sorting and dispensing device technology, applied in garbage bins, garbage collection, garbage cleaning, etc., can solve problems such as failure to clean up in time, space pollution around buried garbage cans, visual and environmental pollution, etc., to reduce uncivilized Garbage throwing behavior, convenient management and decision-making, and the effect of reducing garbage odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

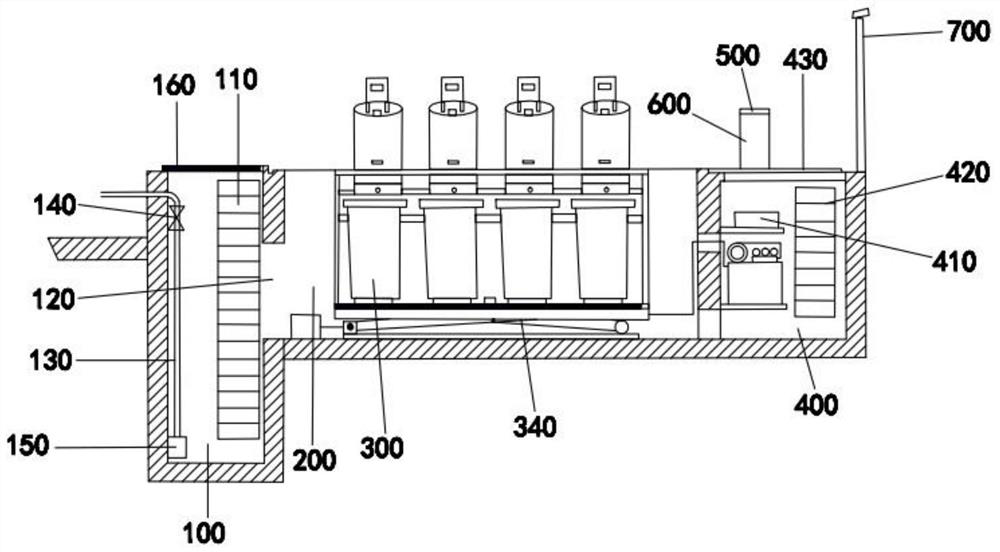

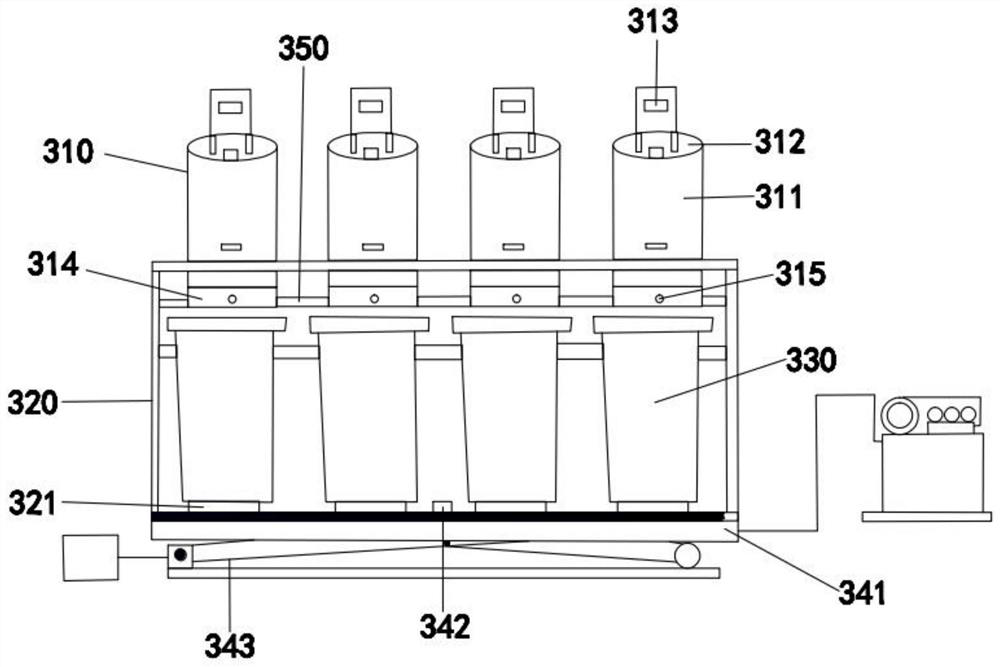

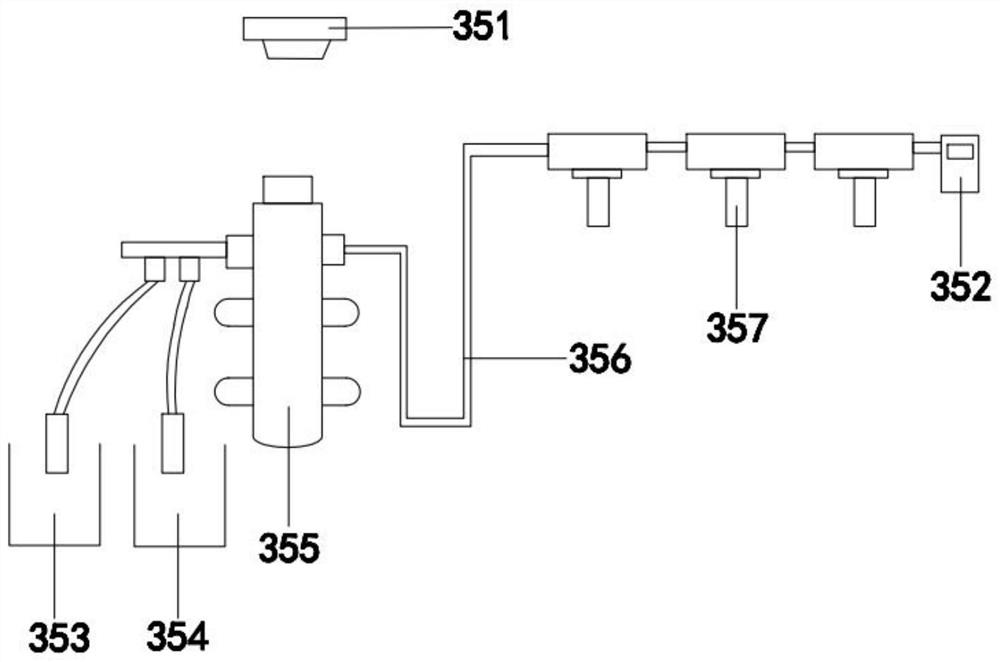

[0034] A sorting and dispensing device for garbage, comprising a maintenance well 100, a garbage sorting room 200, an underground dispensing mechanism 300 and a control room 400, the buried dispensing mechanism 300 is set in the garbage sorting room 200, and the buried The type delivery mechanism 300 includes a garbage delivery port 310 located on the ground and a lifting box 320 located underground, a garbage can 330, a lifting mechanism 340 and a killing mechanism 350, and the garbage can 330, the lifting mechanism 340 and the killing mechanism 350 are all located at Inside the lifting box 320, the garbage delivery port 310 adopts a cylindrical body 311 with open upper and lower ends, and the top of the cylindrical body 311 is provided with a flip cover 312 and a face recognition mechanism 313, and the flip cover 312 passes through the human body. The face recognition mechanism 313 controls the opening and closing. The bottom of the cylinder 311 is provided with a material di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com