Refrigeration method and control system capable of eliminating temperature disturbances

A refrigeration method and control system technology, which are applied in battery/fuel cell control devices, electric vehicles, heating/cooling equipment, etc., can solve the problems of low refrigeration accuracy and poor refrigeration effect, and achieve improved use efficiency, accuracy and reliability. Efficient refrigeration control, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

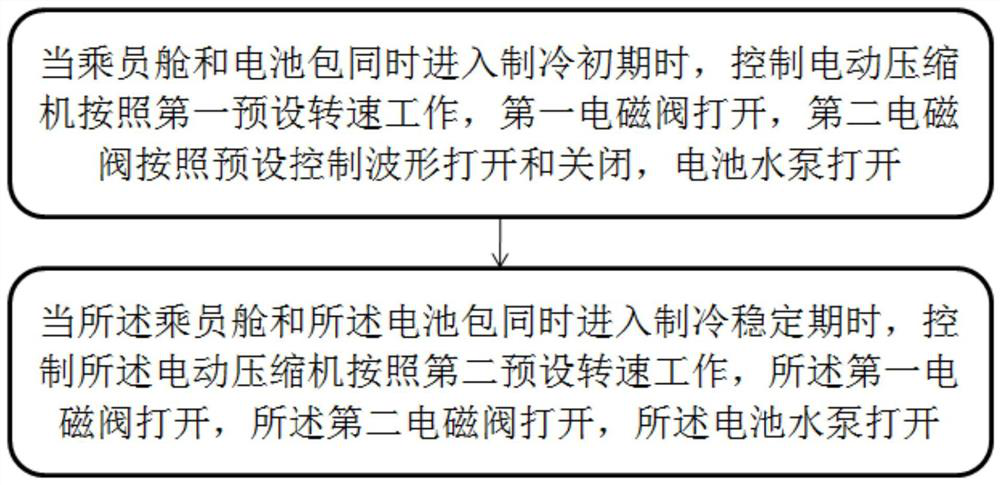

[0048] A refrigeration method for eliminating temperature disturbance provided by an embodiment of the present invention, such as figure 1 As shown, in this embodiment, steps are included:

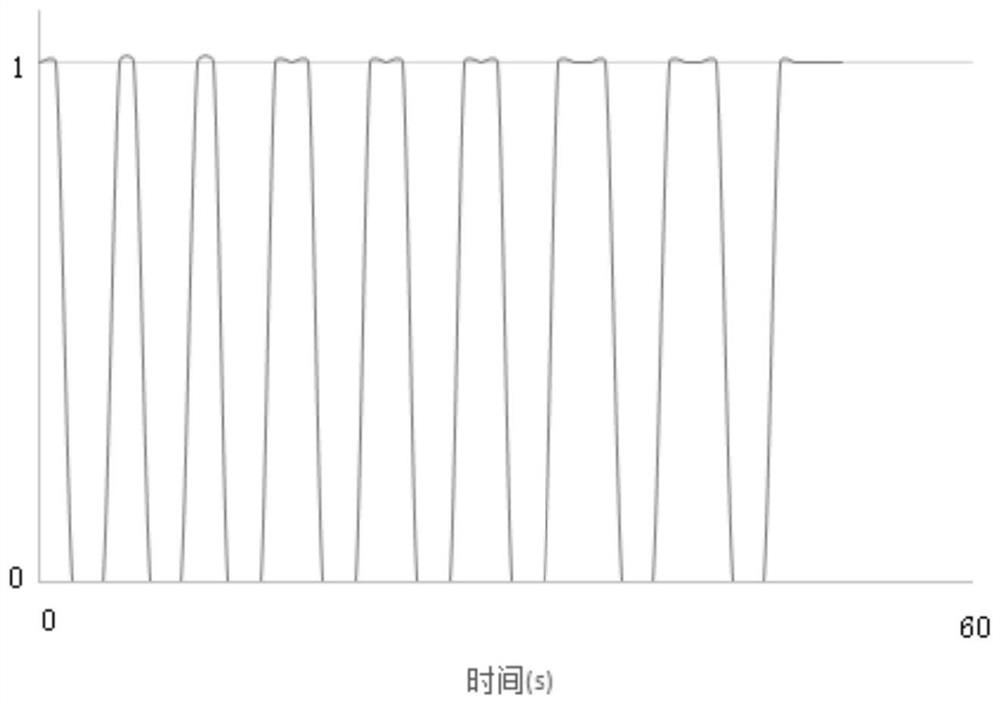

[0049] When the passenger compartment and the battery pack enter the initial cooling stage at the same time, the electric compressor is controlled to work at the first preset speed, the first solenoid valve is opened, the second solenoid valve is opened and closed according to the preset control waveform, and the battery water pump is turned on;

[0050] When the passenger compartment and the battery pack enter the refrigeration stabilization period at the same time, the electric compressor is controlled to work at the second preset speed, the first solenoid valve is opened, the second solenoid valve is opened, and the battery water pump is turned on.

[0051] In this embodiment, by controlling the electric compressor and the first electromagnetic valve to work at the first preset speed an...

Embodiment 2

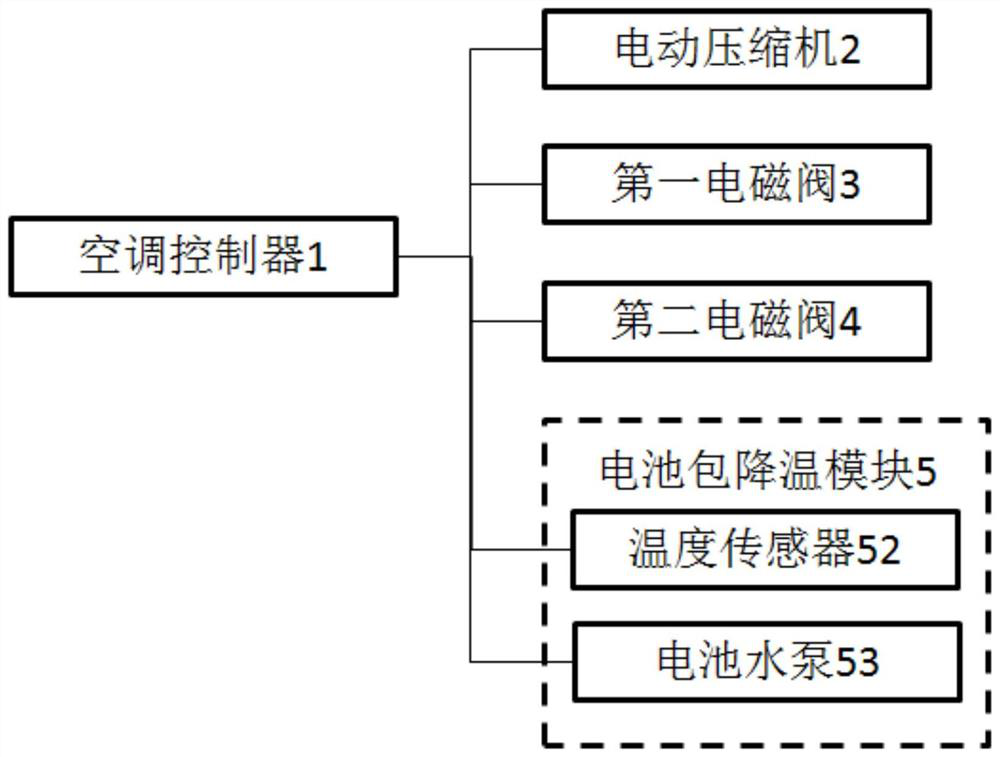

[0079] The reference signs in the accompanying drawings of the description in this embodiment include: air conditioner controller 1, electric compressor 2, first solenoid valve 3, second solenoid valve 4, battery pack cooling module 5, cooling pipeline 51, temperature sensor 52, A battery water pump 53, a condenser 6, a thermal expansion valve 7, a first evaporator 8, and a second evaporator 9.

[0080] see image 3 , Figure 4 , the embodiment of the present invention also provides a control system for eliminating temperature disturbances, running a refrigeration method for eliminating temperature disturbances in Embodiment 1, including an air conditioner controller 1 and an electric compressor 2 electrically connected thereto, and a first solenoid valve 3. The second solenoid valve 4, the battery pack cooling module 5; also includes a condenser 6 connected to the electric compressor 2, a thermal expansion valve 7 and a first evaporator 8 connected to the first solenoid valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com