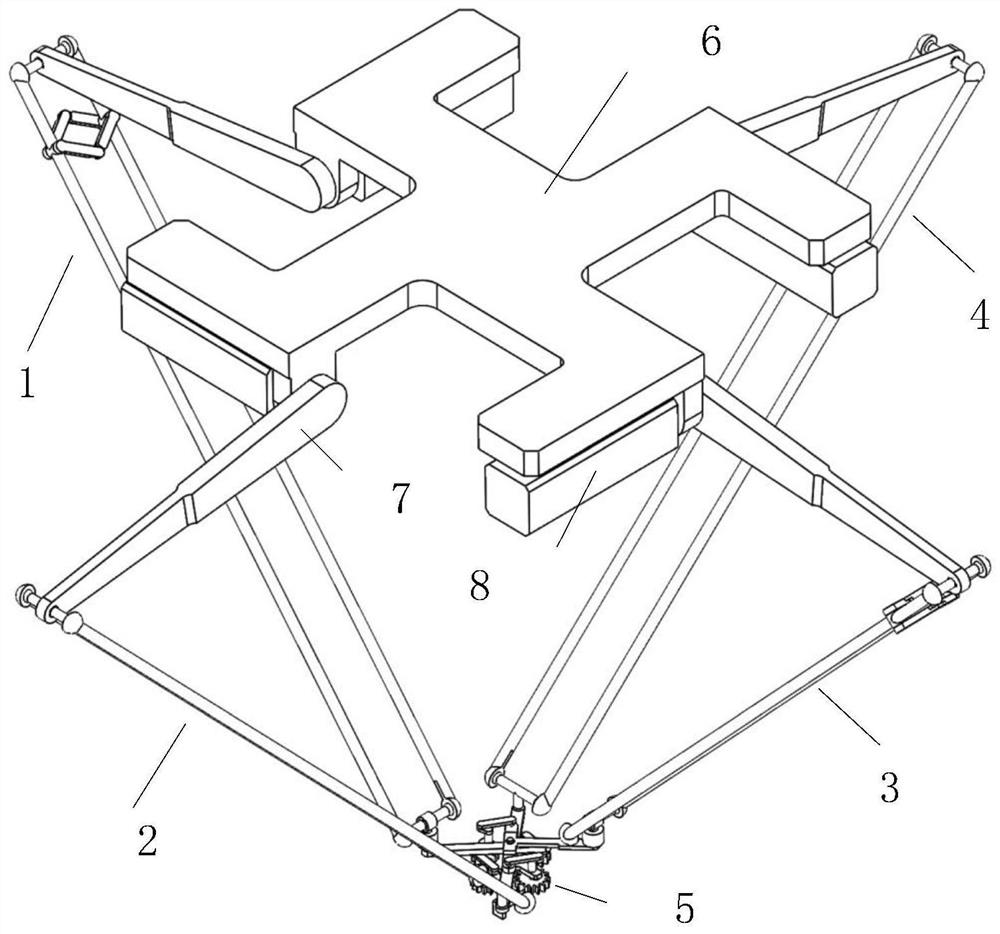

Four-degree-of-freedom high-speed parallel robot with continuous rotation capability

A degree of freedom and robot technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as inability to realize infinite rotation, and achieve the effect of improving dynamic response quality and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments of the present invention will be described in detail below with reference to the drawings in the embodiments of the present invention. The described embodiments are merely a part of the embodiments of the invention.

[0024] The technical solution to solve the above technical problem is:

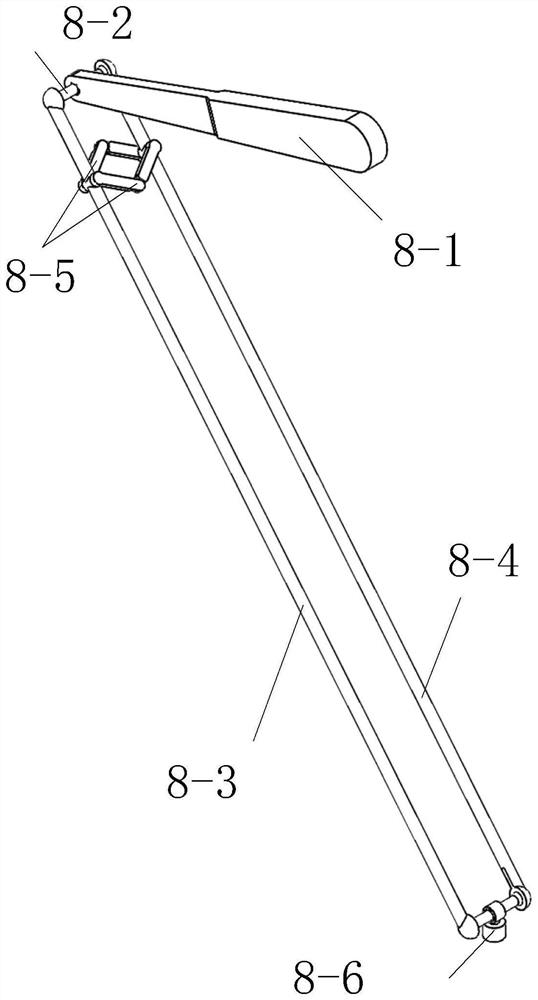

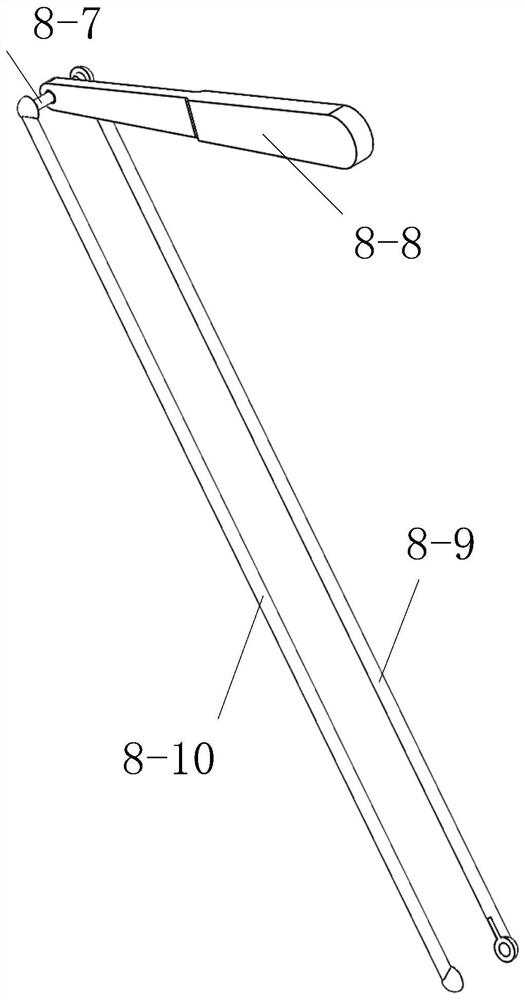

[0025] like Figure 1-11As shown, the present invention has a four-degree-freedom high-speed parallel robot having a continuous rotation capacity, which includes a platform, a movable platform, and a first strand, a second strand arranged between the platform and movable platform. , The third strand and fourth strand; four driving devices are arranged on the confinement platform; the first strand and the third strand structure are the same, and both include driving arms A, upper connecting rod A, Left link A, right link A, diamond chain and lower connecting rod A; one end of the drive arm A and the fixed platform by rotating the secondary connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com