A vacuum-driven radial automatic positioning device

A positioning device and automatic positioning technology, used in positioning devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of affecting processing efficiency, large deviation of knocking amount, time-consuming and laborious, etc., to achieve convenient operation and reliable positioning. 、Reliable and accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

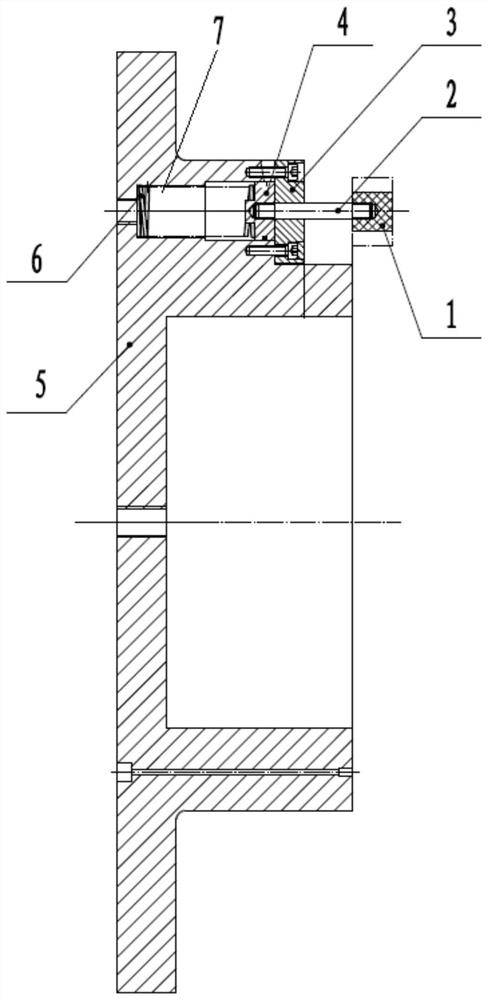

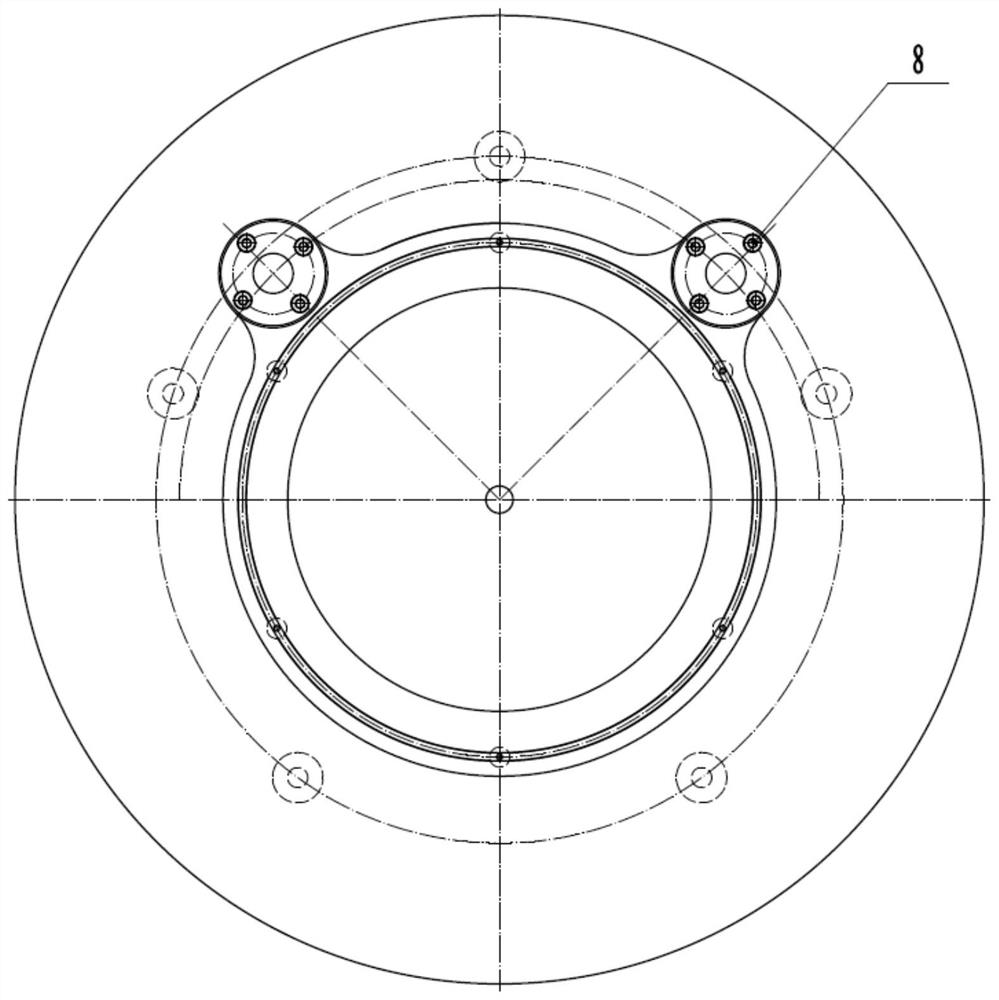

[0023] Such as figure 1 and 2 As shown, a vacuum-driven radial automatic positioning device includes a vacuum chuck 5 for absorbing workpieces. Two positioning devices 8 are provided on the vacuum chuck 5, and the two positioning devices 8 are arranged along the axis of the vacuum chuck 5. Slidingly connected to the vacuum chuck 5, the two positioning devices 8 are arranged on a concentric circle with the axis of the vacuum chuck 5 as the center, and the connecting line between the two positioning devices 8 does not pass through the center of the concentric circle.

[0024] The present invention designs a set of vacuum-driven radial automatic positioning devices aimed at the problems in the background technology. This device adopts a vacuum-driven mode to realize the radial positioning device 8, which can automatically lift according to actual needs. When positioning is required, the positioning device 8 will automatically Lift out to play a positioning role. When the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com