Appearance defect detection equipment and detection method thereof

A technology for appearance defects and detection equipment, which is applied in optical testing flaws/defects, measuring devices, material analysis by optical means, etc. High requirements, to achieve the effect of being conducive to large-scale testing, high work efficiency, and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

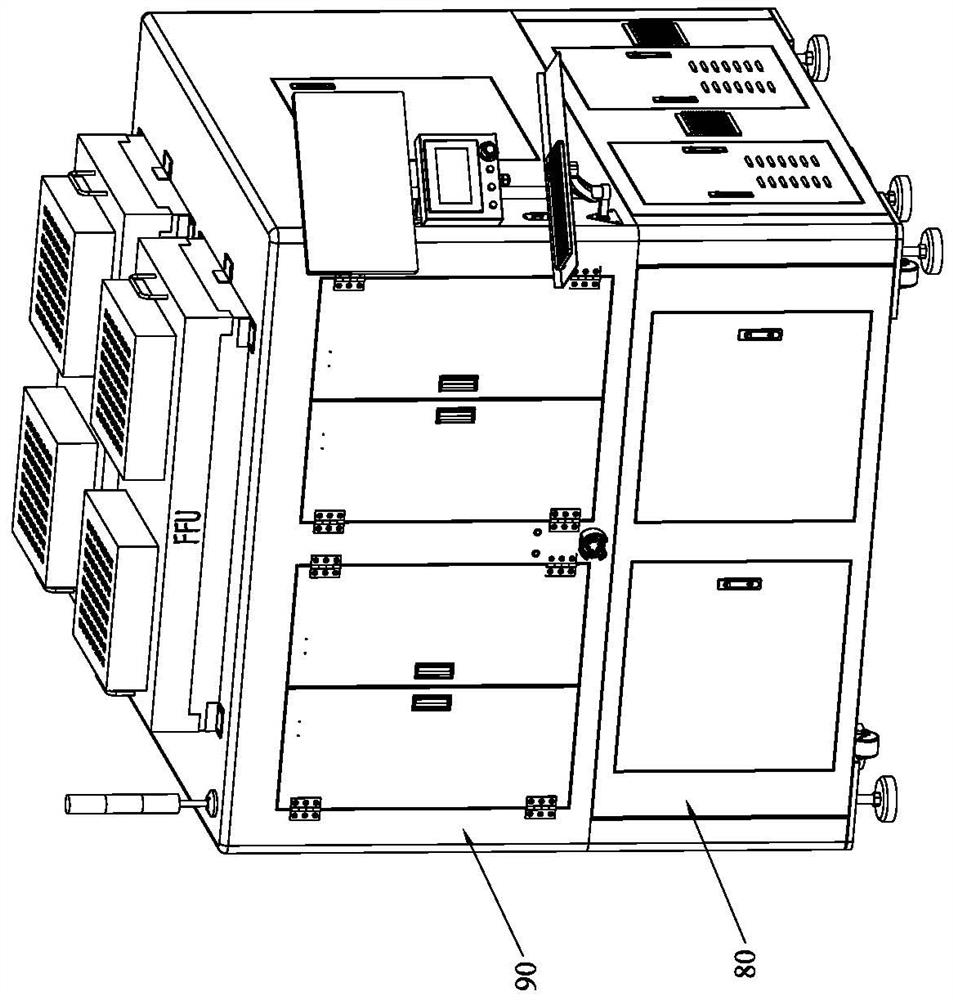

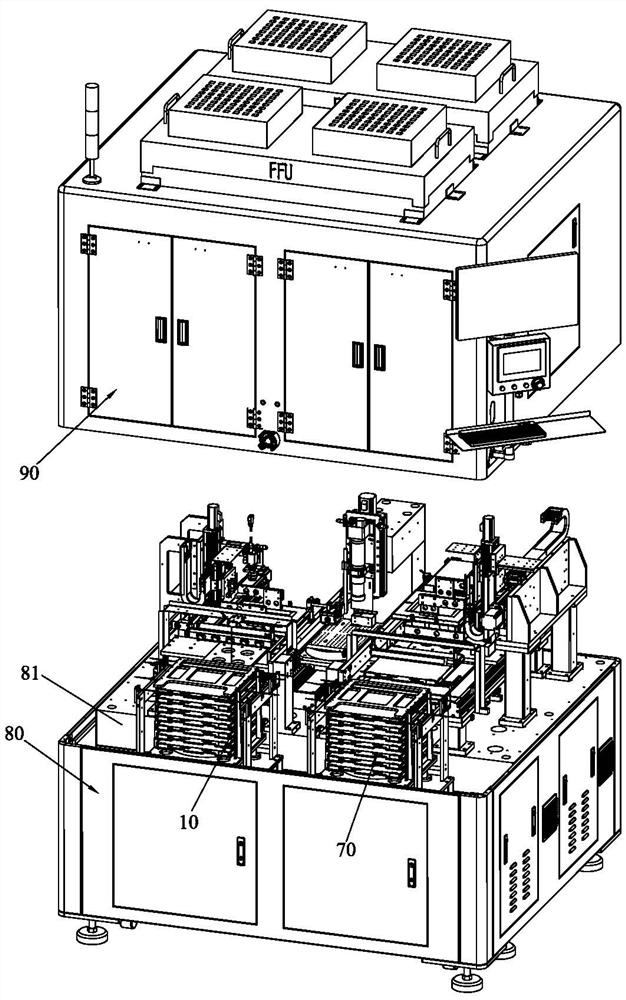

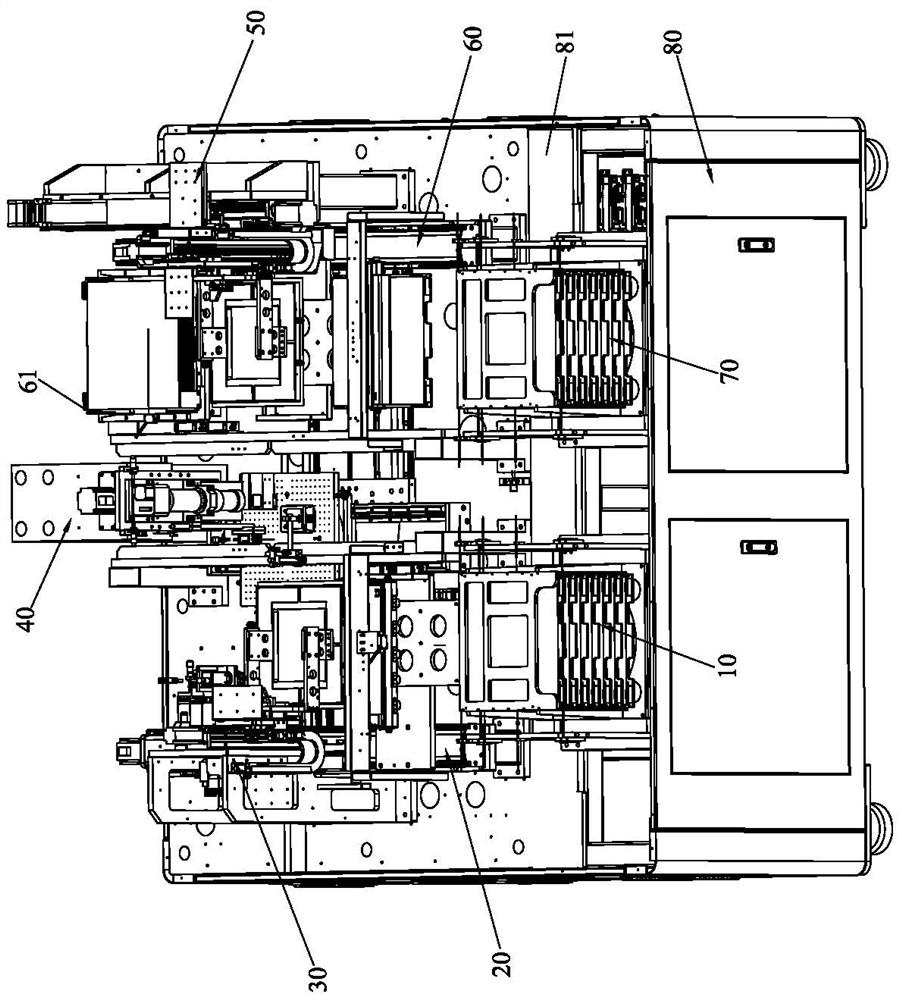

[0061] Please refer to Figure 1 to Figure 11As shown, it has shown the specific structure of a preferred embodiment of the present invention, including a feeding tray warehouse 10, a feeding and transplanting device 20, a feeding conversion mechanism 30, a CCD detection mechanism 40, and a feeding conversion mechanism arranged in sequence. Mechanism 50, blanking and transplanting device 60 and blanking tray warehouse 70;

[0062] Both the loading and transplanting device 20 and the blanking and transplanting device 60 are arranged along the X axis, and the loading and transferring mechanism 30 and the unloading and converting mechanism 50 are arranged on the loading and transplanting device 20 and the blanking and transplanting device respectively. On the outside of the device 60 , the CCD detection mechanism 40 is arranged between the inside of the loading and transplanting device 20 and the inside of the unloading and transplanting device 60 .

[0063] The loading and tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com