An electrical box installation device for an electric vehicle

An electric vehicle and installation device technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of cumbersome removal of the end cover of the electrical box, reducing the volume of the electrical box installation device, and reducing the re-installation efficiency of the electrical box, etc. Achieve the effect of promoting contact, saving installation operations, and shortening installation operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

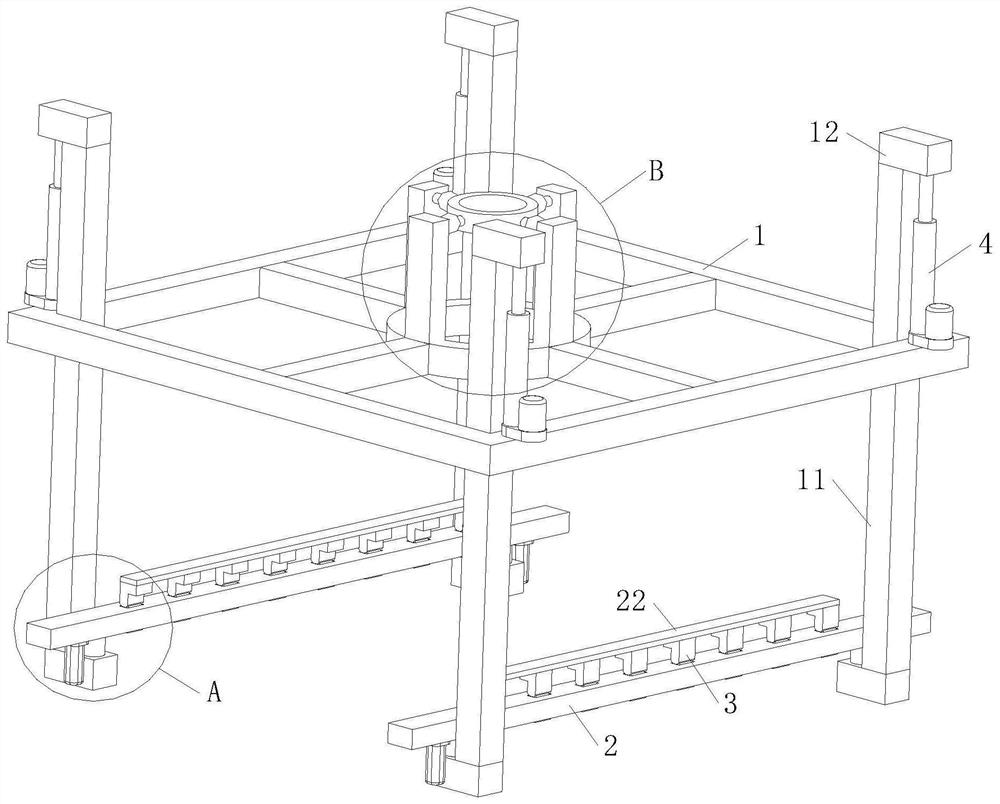

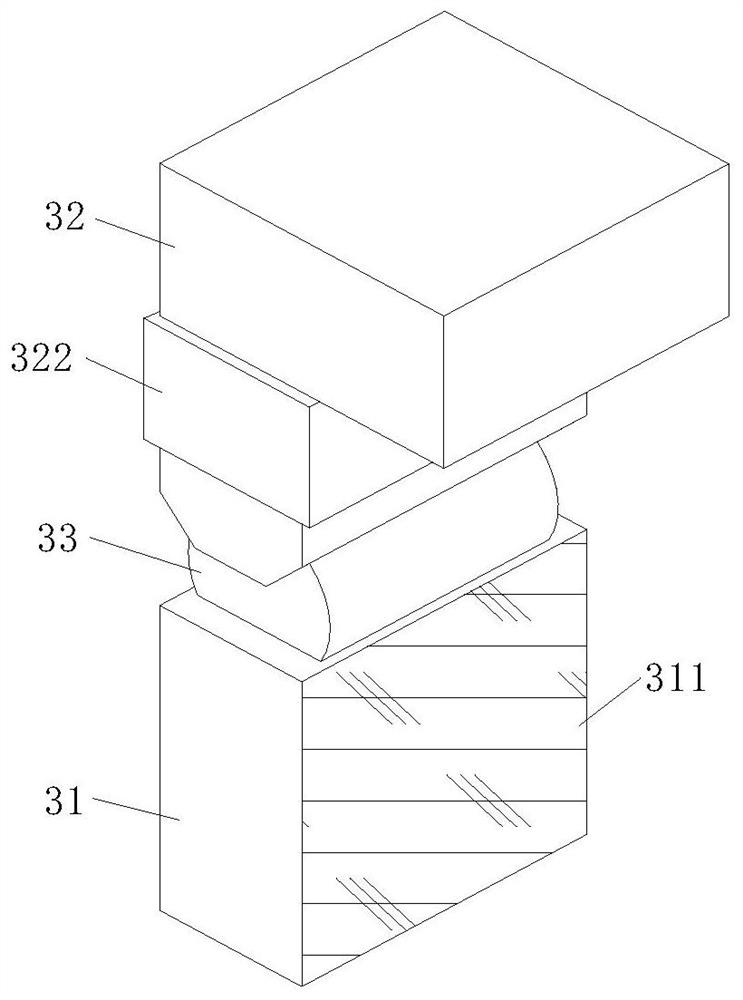

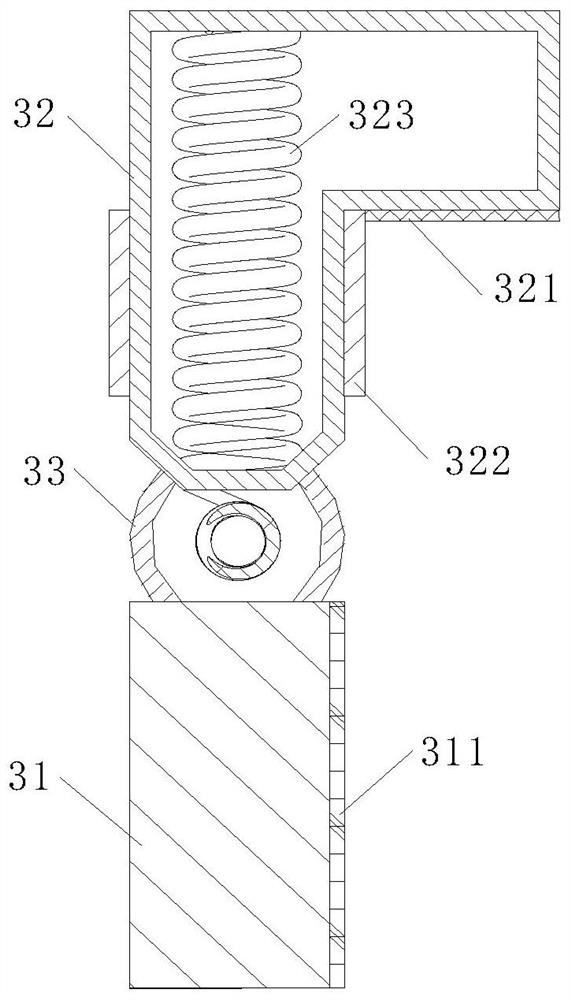

[0025] As an embodiment of the present invention, the straight sleeve 31 is provided with an embedded wood chip 311, and the wood chip 311 is located on the surface of the straight sleeve 31 in contact with the electrical box; the surface of the curved sleeve 32 in contact with the end cover is provided with Rubber pad 321; After the sleeve clamp 3 has installed the end cover on the flange of the electrical box port, the installation hole port on the electrical box flange will cause a difference between the contact surface between the sleeve clamp 3 and the electrical box, resulting in a straight sleeve 31 The stress distribution on the contact surface with the curved sleeve 32 is uneven, causing the deformation of the surface of the straight sleeve 31 and the curved sleeve 32, and weakening the sealing performance between the electrical box and the end cover; the present invention is arranged on the straight sleeve 31 The wood chip 311 on the top and the rubber pad 321 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com