Vertical rocker arm type automatic nozzle

A vertical rocker arm and sprinkler technology, which is applied in the field of vertical rocker automatic sprinklers, can solve the problems of small columnar water spray irrigation area, inconvenient use, and low sprinkler area, and achieve the goal of increasing speed, increasing sprinkler area, and improving spray irrigation range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

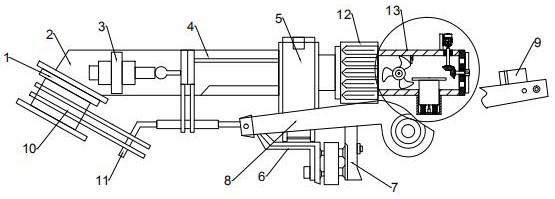

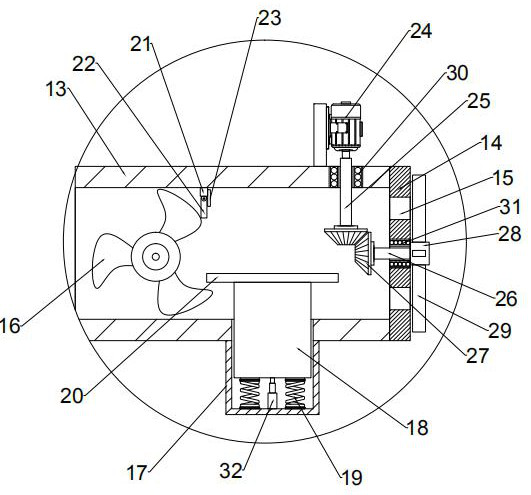

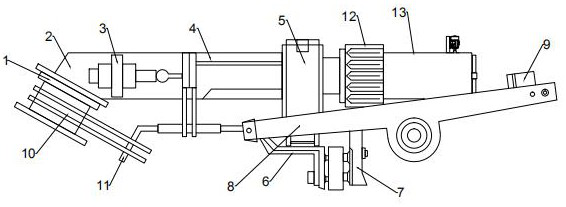

[0023] Embodiment 1: According to Figure 1-3 It can be seen that for a vertical rocker-arm type automatic sprinkler, when the water flow enters the sprinkler 13 through the steady flow pipe 4, the water flow will impact the spiral impeller 16 to make it rotate counterclockwise, and the rotation of the spiral impeller 16 will also initially disperse the water flow to avoid water flow. Spray in piles to effectively save water resources. Since one end of the horizontal plate 20 is located on the rotation track of the spiral impeller 16, when the spiral impeller 16 rotates counterclockwise, it will contact the lower wall of the horizontal plate 20, and then drive the horizontal plate 20 Synchronous upward rise, at this time the inner diameter of the nozzle 13 decreases. According to the principle of fluid acceleration, the water flow will be accelerated by pressurization at this time, and finally enter the top cover 14, and spray out from the water spray hole 15. At this time, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com