Dry desulfurization agent and preparation method thereof

A dry desulfurization and catalyst technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of air pollution, acid rain, low utilization rate, etc., so as to overcome the low utilization rate and improve the desulfurization reaction rate. , the effect of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

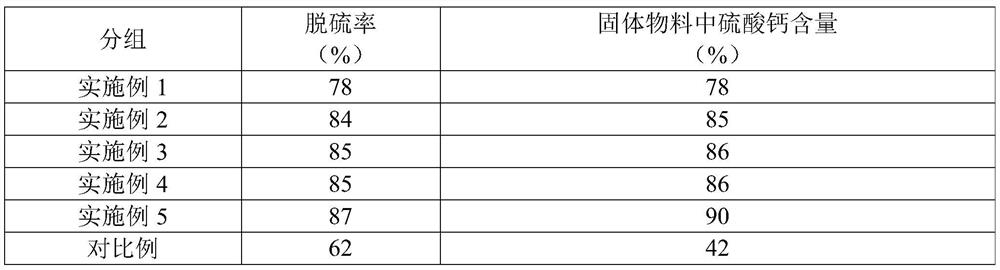

Examples

Embodiment 1

[0027] Preparation of modified nano-calcium carbonate:

[0028] Weigh 100 parts of nano-calcium carbonate and 5 parts of sodium dodecylsulfonate respectively, put them into a kneader after mixing, keep the stirring speed at 10r / min, kneading pressure at 0.2MPa, and knead and stir for 0.5h to obtain modified nano-calcium calcium carbonate.

[0029] Weigh 0.1 part of nano-iron oxide and 0.1 part of activated carbon, put them into the mixer respectively, and stir for 30 minutes at a rotating speed of 50r / min to obtain the first mixture, mix the first mixture with modified nano-calcium carbonate and put it into Stir in a mixer for 2 hours at a speed of 50 r / min to obtain a dry desulfurizer.

Embodiment 2

[0031] Preparation of modified nano-calcium carbonate:

[0032] Weigh 100 parts of nano-calcium carbonate and 20 parts of sodium stearate respectively, mix them and put them into a kneader, keep the stirring speed at 30r / min, the kneading pressure at 0.5MPa, and knead and stir for 1h to obtain the modified nano-calcium carbonate.

[0033] Weigh 1 part of nano-zinc oxide and 1 part of activated carbon, put them into the mixer respectively, and stir for 60 minutes at a speed of 100r / min to obtain the first mixture, mix the first mixture with modified nano-calcium carbonate and put it into Stir in a mixer for 4 hours at a speed of 100 r / min to obtain a dry desulfurizer.

Embodiment 3

[0035] Preparation of modified nano-calcium carbonate:

[0036] Weigh 100 parts of nano-calcium carbonate and 10 parts of sodium lignosulfonate respectively, mix them and put them into a kneader, keep the stirring speed at 20r / min, the kneading pressure at 0.3MPa, and knead and stir for 40min to obtain modified nano-calcium carbonate.

[0037] Weigh 0.5 parts of nano-manganese dioxide and 0.5 parts of activated carbon, put them into the mixer respectively, and stir for 40 minutes at a speed of 80r / min to obtain the first mixture, mix the first mixture with modified nano-calcium carbonate and put into Put it into a mixer, and stir it for 3 hours at a speed of 80r / min to obtain a dry desulfurizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com