Agricultural corn threshing equipment

A corn threshing and equipment technology, applied in threshing equipment, applications, agriculture, etc., can solve problems such as low efficiency and difficulty in ensuring safety, and achieve the effect of preventing falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

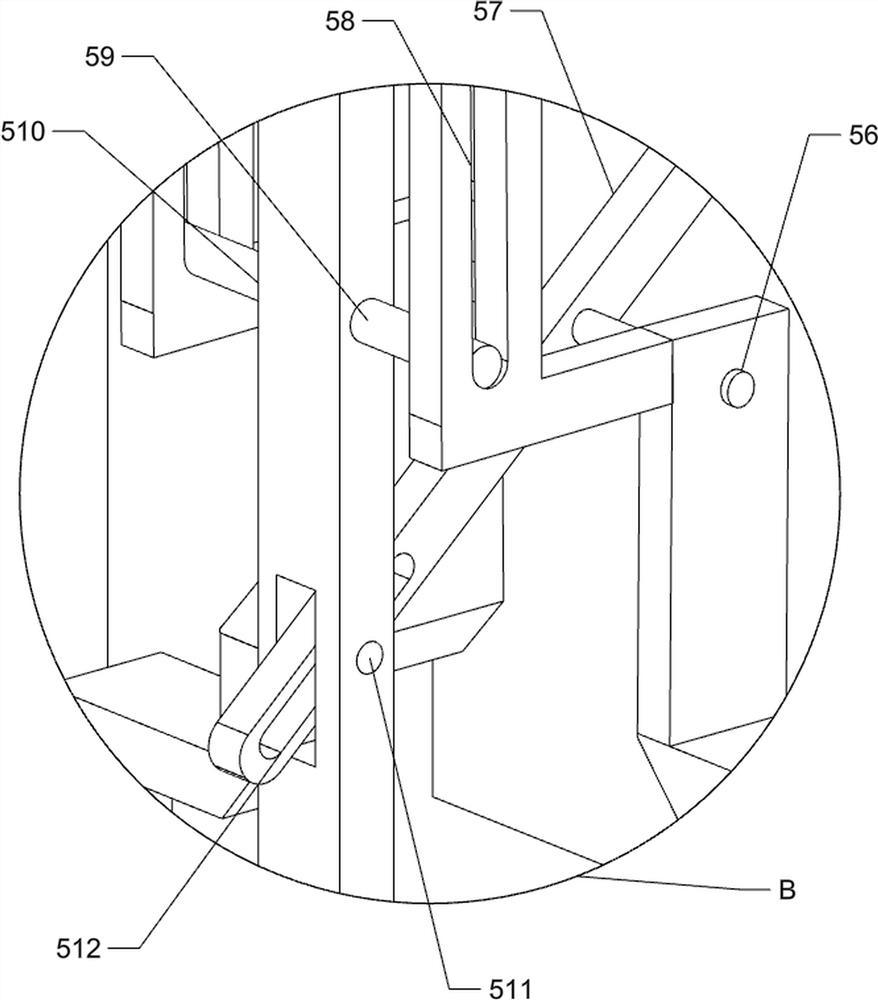

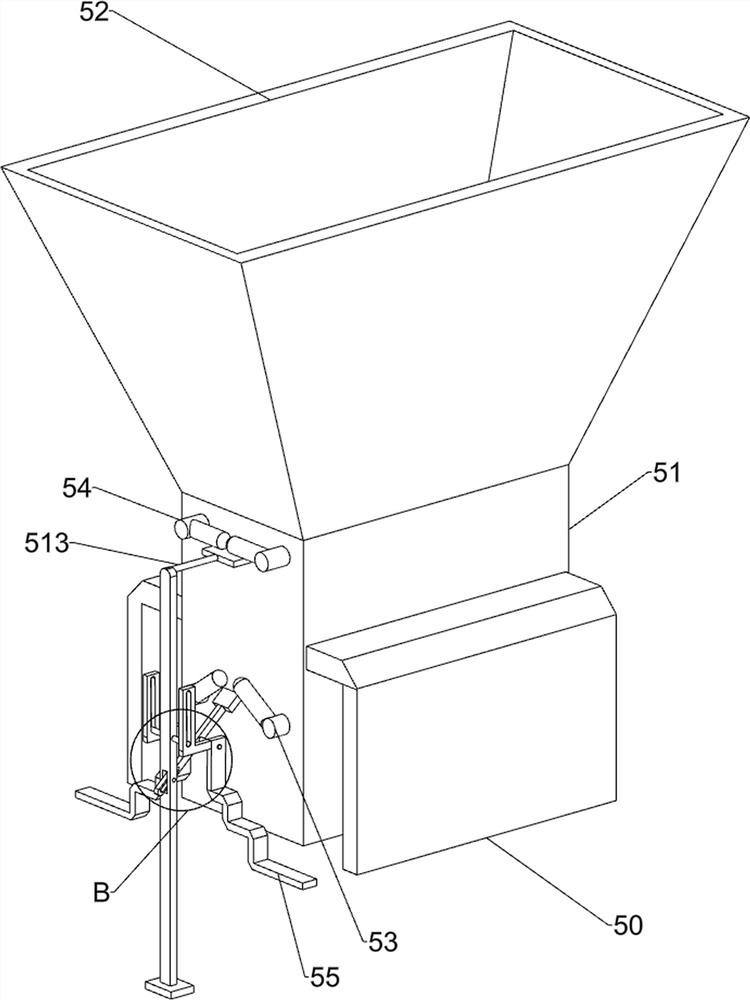

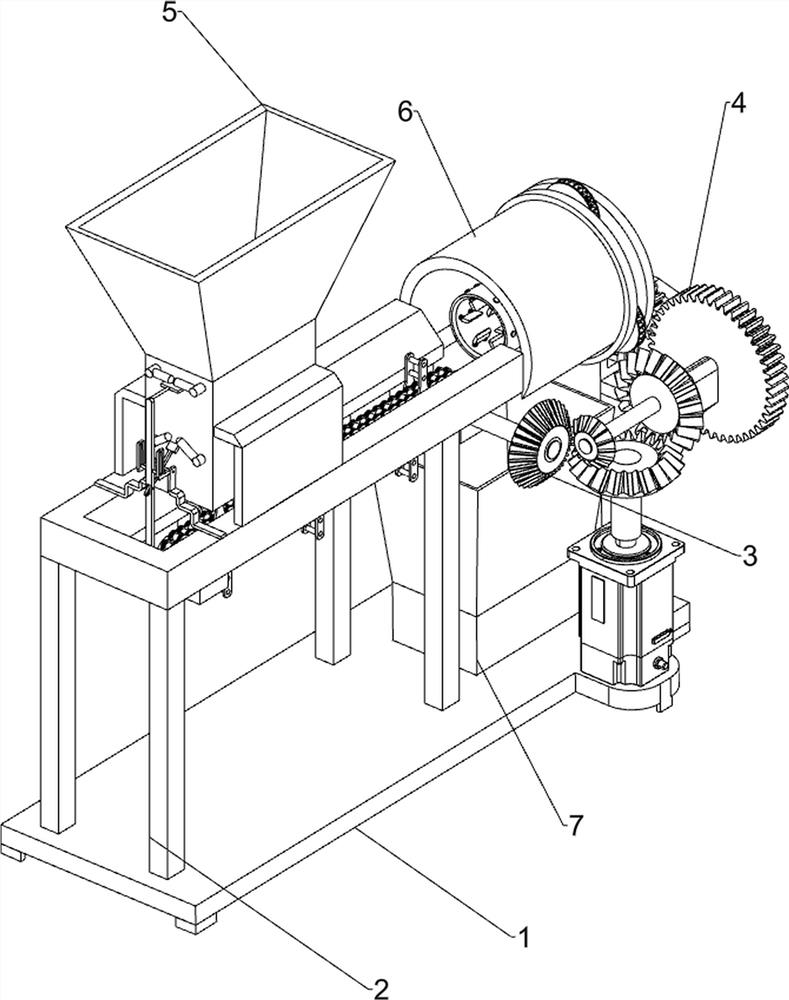

[0048] A kind of agricultural corn threshing equipment, such as figure 1 As shown, it includes a bottom plate 1, a first support frame 2, a pushing mechanism 3 and a threshing mechanism 4, the left side of the top of the bottom plate 1 is provided with a first support frame 2, and the upper part of the first support frame 2 is provided with a pushing mechanism 3. A threshing mechanism 4 is connected between the front side of the feeding mechanism 3 and the right side of the bottom plate 1 top.

[0049] When the staff needs to thresh the corn, first start the threshing mechanism 4 to drive the pushing mechanism 3 to work, then put the corn horizontally on the top of the first support frame 2, and the pushing mechanism 3 works to transfer the corn to the threshing mechanism 4 Inside, the threshing mechanism 4 can thresh the corn, after the threshing is completed, stop the threshing mechanism 4, and the staff can collect it again.

Embodiment 2

[0051] On the basis of Example 1, such as figure 2 As shown, the pusher mechanism 3 includes a first bearing seat 30, a chain set 31, a pusher head 32, a first rotating shaft 33 and a differential bevel gear set 34, and the top of the first support frame 2 is U-shaped with an opening on the right side. Both sides of the bottom of the first support frame 2 are symmetrically provided with a first bearing seat 30, and a chain group 31 is rotatably connected between the first bearing seat 30, and a pusher head 32 is evenly arranged on the chain group 31, and the first bearing on the right side The front side of the seat 30 is rotatably provided with a first rotating shaft 33, and a differential bevel gear set 34 is provided between the front side of the first rotating shaft 33 and the left side of the threshing mechanism 4.

[0052] After the corn is placed on the chain group 31 in the top of the first support frame 2, the threshing mechanism 4 drives the first rotating shaft 33 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com