Fixing device and fixing method for transverse tensile test of ceramic-based fiber bundle composite material

A composite material, transverse stretching technology, applied in the direction of measuring devices, analytical materials, instruments, etc., can solve the problems of small size, inability to obtain transverse tensile mechanical properties data of ceramic matrix fiber bundle composite materials, etc., to improve the success rate, The effect of preventing damage and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0052] The fixture device for transverse tensile test of ceramic-based fiber bundle composite material in this embodiment includes a transverse tensile sample 1, a centering sample preparation device 2 and a transverse tensile fixture 3,

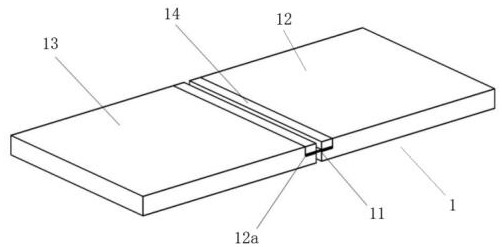

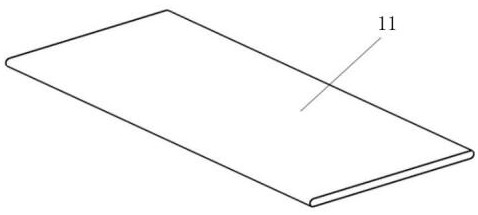

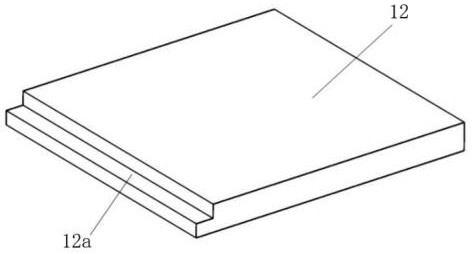

[0053] Such as figure 1 As shown, the transverse tensile sample 1 is composed of a sheet-shaped ceramic matrix fiber bundle composite material 11 (see figure 2 ), the front plate reinforcing sheet 12 and the rear plate reinforcing sheet 13 (see image 3 ), the rear end of the front plate reinforcing sheet 12 and the front end of the rear plate reinforcing sheet 13 are all designed with a fixed step groove 12a, and the front and rear ends of the sheet-shaped ceramic-based fiber bundle composite material 11 are respectively placed on the front plate reinforcing sheet 12 and The back panel reinforcing sheet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com