Method for solving zero tooth abrasion of variable pitch bearing of wind generating set

A technology for wind turbines and pitch bearings, which is applied in the assembly of wind turbines, wind turbines, and trial operation of wind turbines, can solve problems such as wear and zero tooth wear, reduce economic losses, prolong service life, shorten the The effect of the field maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific examples.

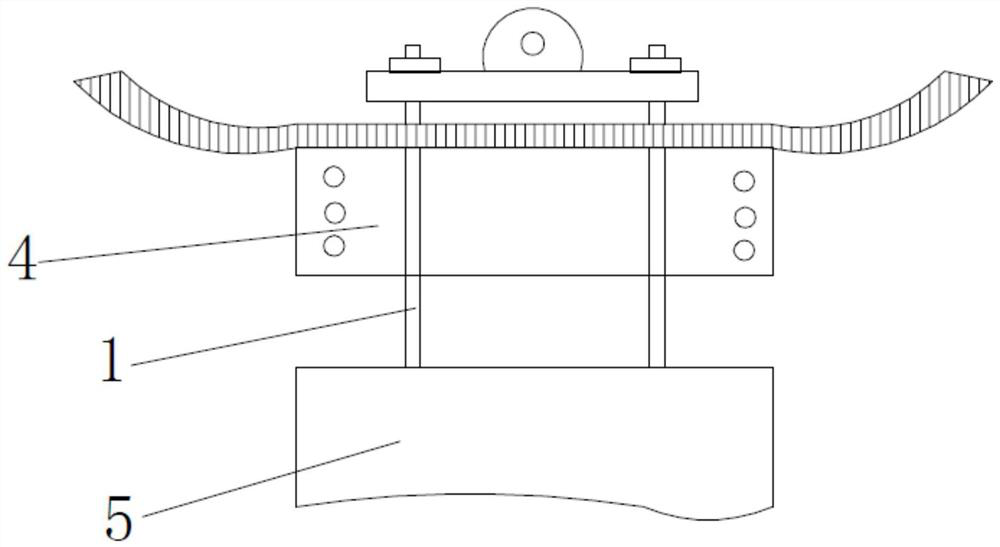

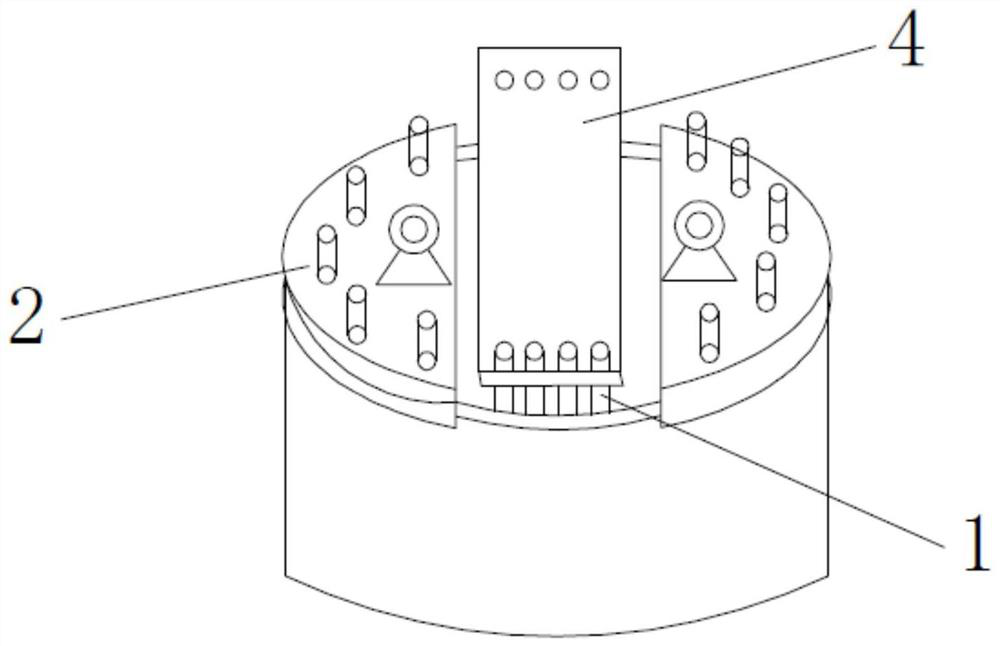

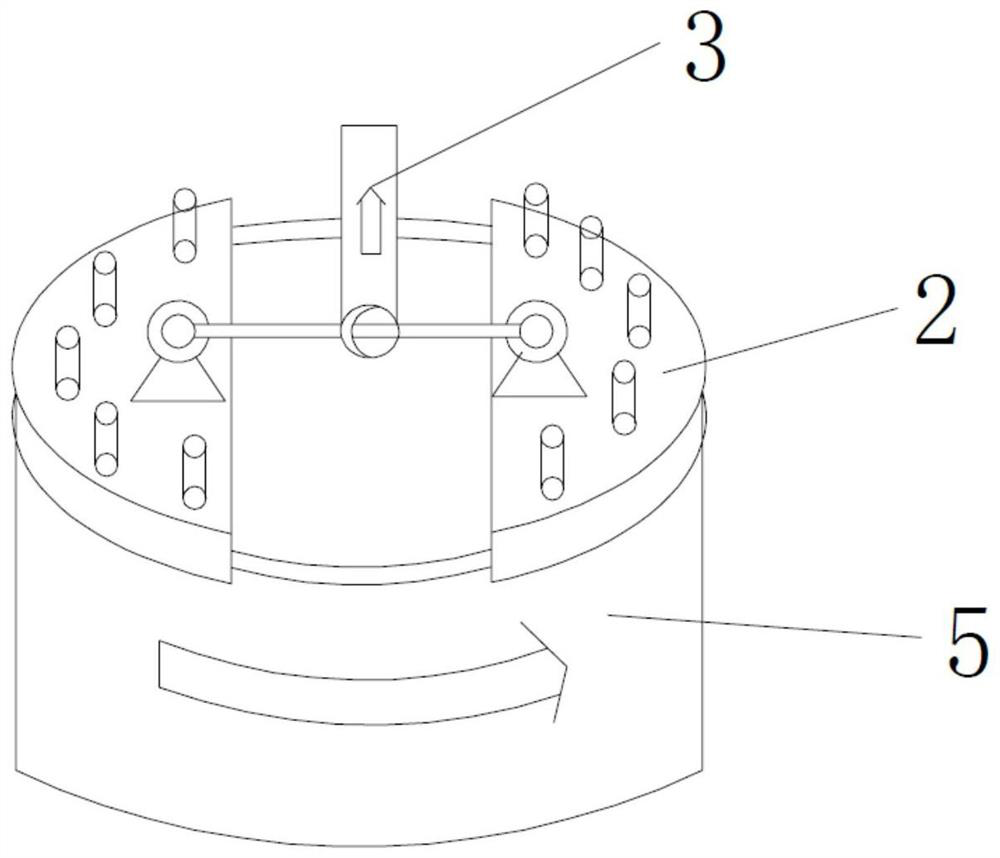

[0019] The method for solving the zero gear wear of the wind turbine pitch bearing described in this embodiment needs to be equipped with: high-strength bolts 1, connecting plates 2, lifting devices 3 and zero pointers, and there are 8 high-strength bolts 1 (the quantity is determined according to the total number of connecting bolts between the pitch bearing 4 and the blade 5, preferably 5% to 10% of the total connecting bolts), the length of the high-strength bolt 1 is greater than the length of the connecting bolt; There are two plates 2, and the connecting plate 2 is an inferior bow structure, such as Figure 4 As shown, its arc edge shape adapts to the shape of blade 5 edge, and its surface is provided with lifting ring 201, is used for being connected with hoisting device 3, is processed with a plurality of bolt holes 202 on it, and is consistent with the bolt hole on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com