Civil engineering construction safety frame

A technology of civil engineering and safety frame, which is applied in the direction of separation method, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of unreachable protection, low strength, and manpower consumption, so as to save manpower and time, avoid rigid impact, Reduce the effect of rigid shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments, and any improvement or substitution in the basic spirit of the present embodiment still belongs to the protection of the claims of the present invention. scope.

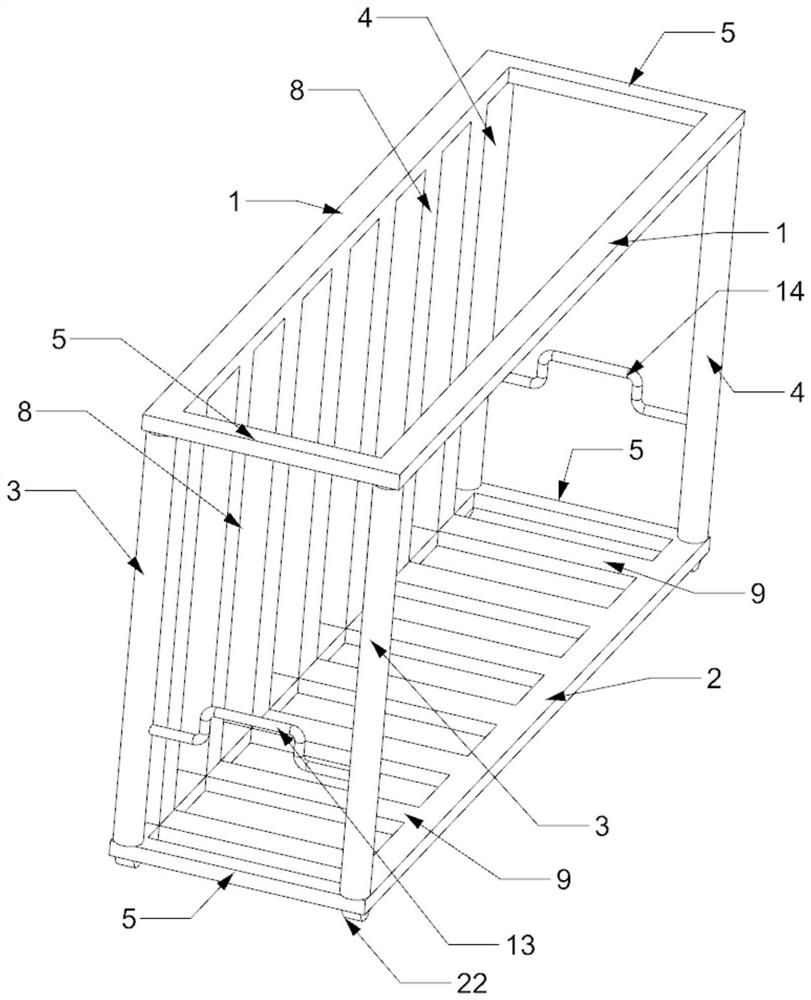

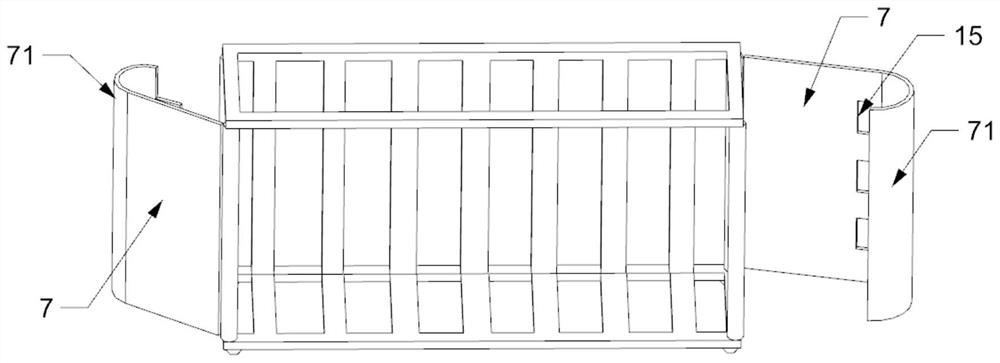

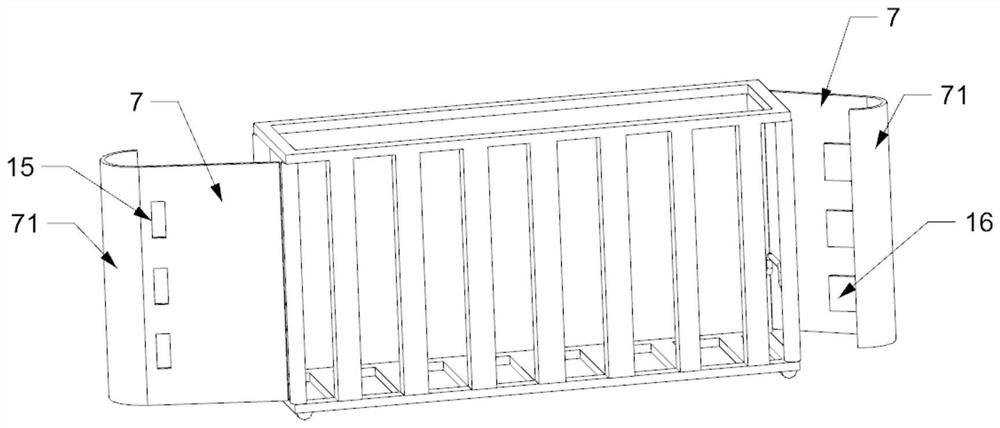

[0029] Example: as Figure 1-6 As shown, a safety frame for civil engineering construction includes a plurality of safety frame assemblies connected end to end, the safety frame assembly includes a frame and a dust collecting mechanism arranged on the frame; the frame of the safety frame assembly is divided into a front frame and a The rear frame, the front frame and the rear frame both include a rectangular frame composed of an upper beam 1, a lower beam 2, a left column 3, and a right column 4, and four corners of the front and rear frames are provided with all The front frame and the rear frame are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com