Intelligent multi-functional sewing machine

A multi-functional, sewing machine technology, applied in the direction of sewing machine components, sewing machine control devices, sewing machine thread cutting mechanism, etc., can solve the problems of high cost, poor product stability and durability, complex structure, etc., to improve rigidity and Stability, stable and reliable performance, and the effect of improving sewing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the application will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the application can be more easily understood by those skilled in the art, so as to make a clearer definition of the protection scope of the application. These implementation modes It is only used to illustrate the present invention, but not to limit the present invention.

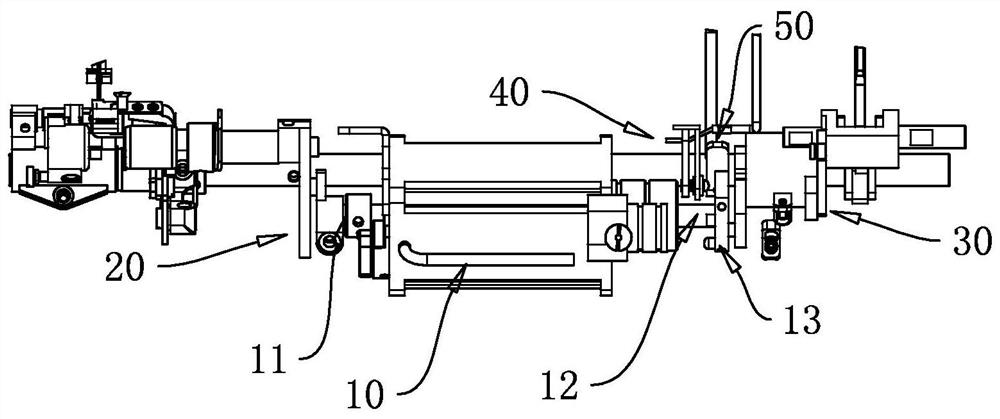

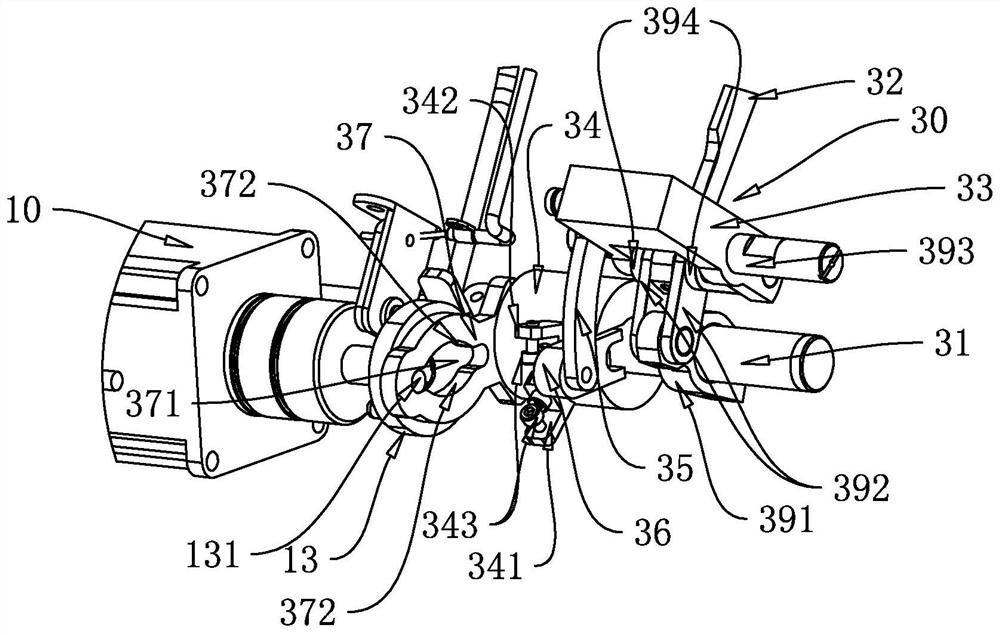

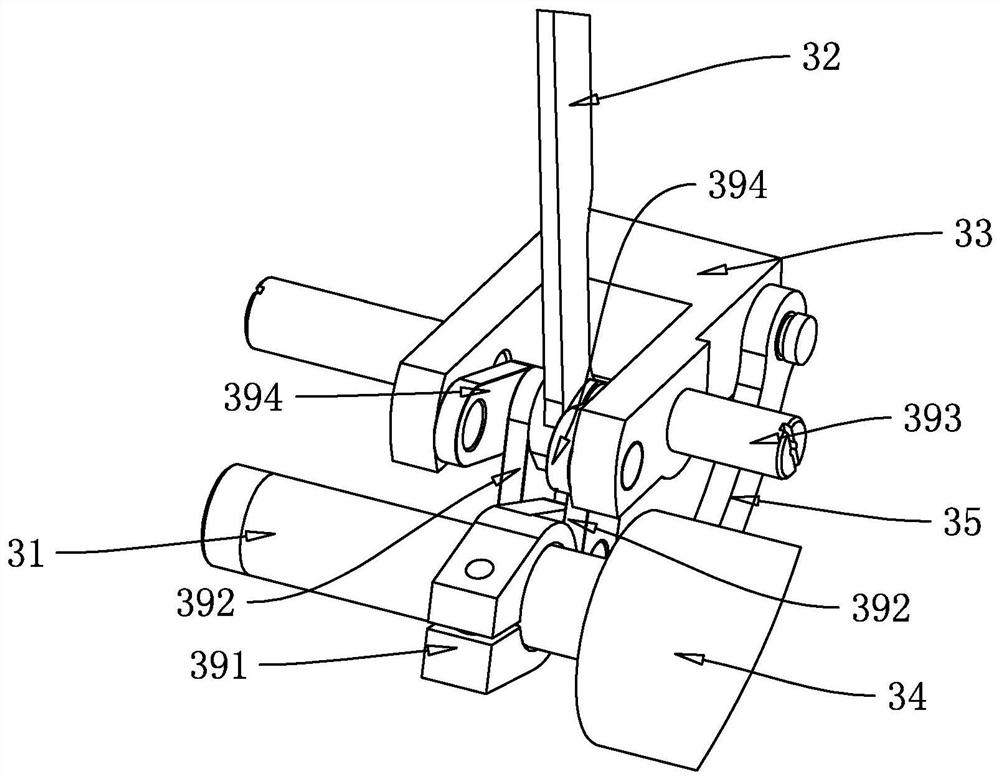

[0030] figure 1 It is a diagram of an intelligent multifunctional sewing machine of the present application, which has a driving source 10, which is a driving device for double-head output power. The driving source 10 has a front output shaft 11 and a rear output shaft 12, and the driving source 10 rotates and drives the front The output shaft 11 and the rear output shaft 12 run in rotation. The driving source 10 of the present application controls the thread trimming mechanism 20, the automatic adjustment mechanism 30 of the needle dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com