Fermented soya bean making machine with yeast spreading and crushing functions

A technology of making machine and crushing mechanism, which is applied in the method of sampling biological materials, the method of forming food, and the method of sterilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

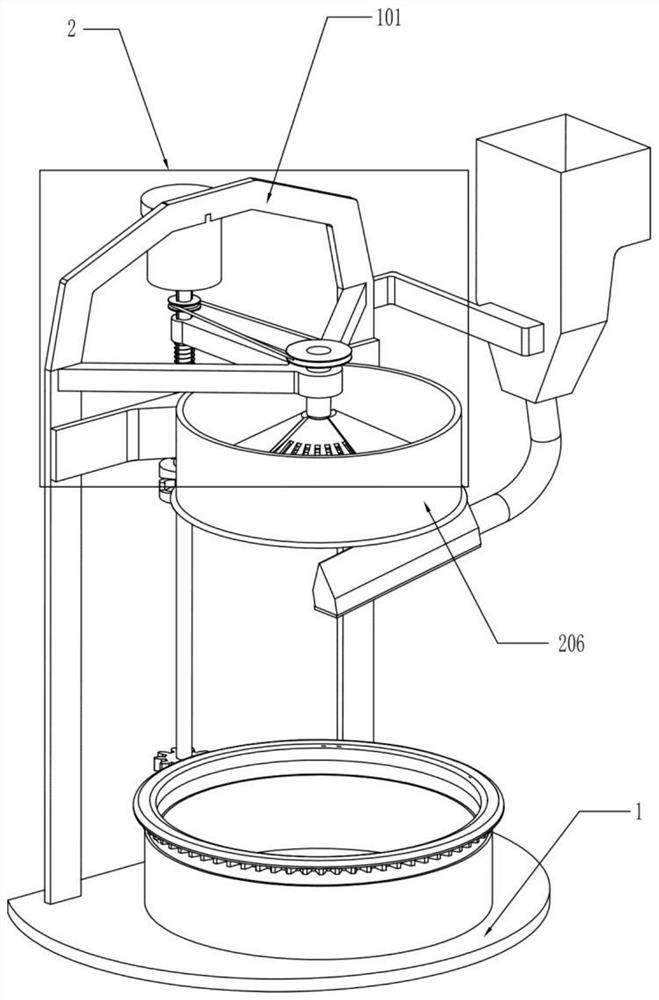

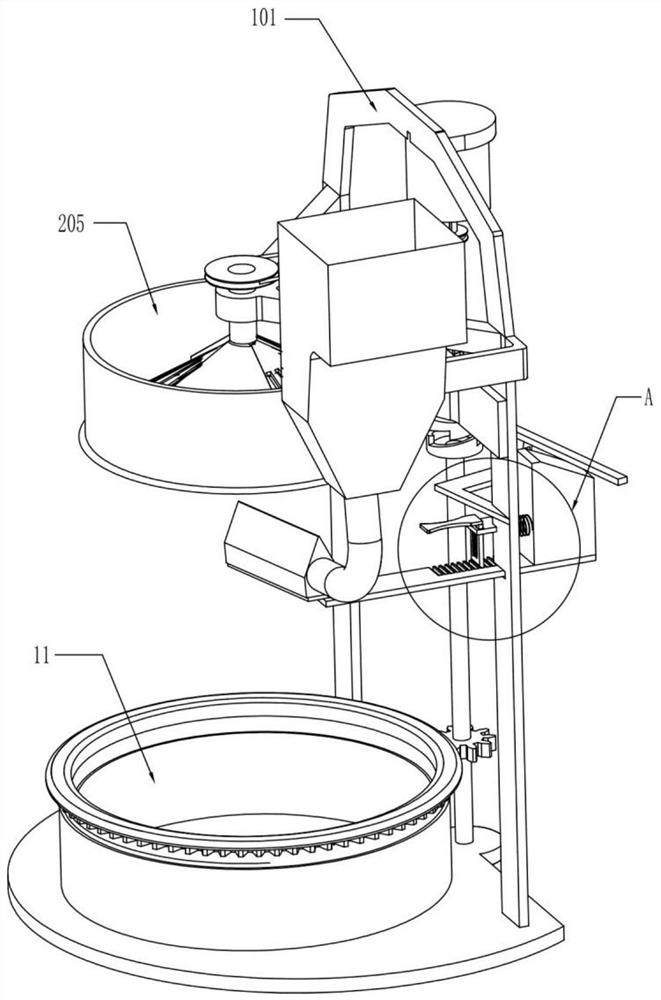

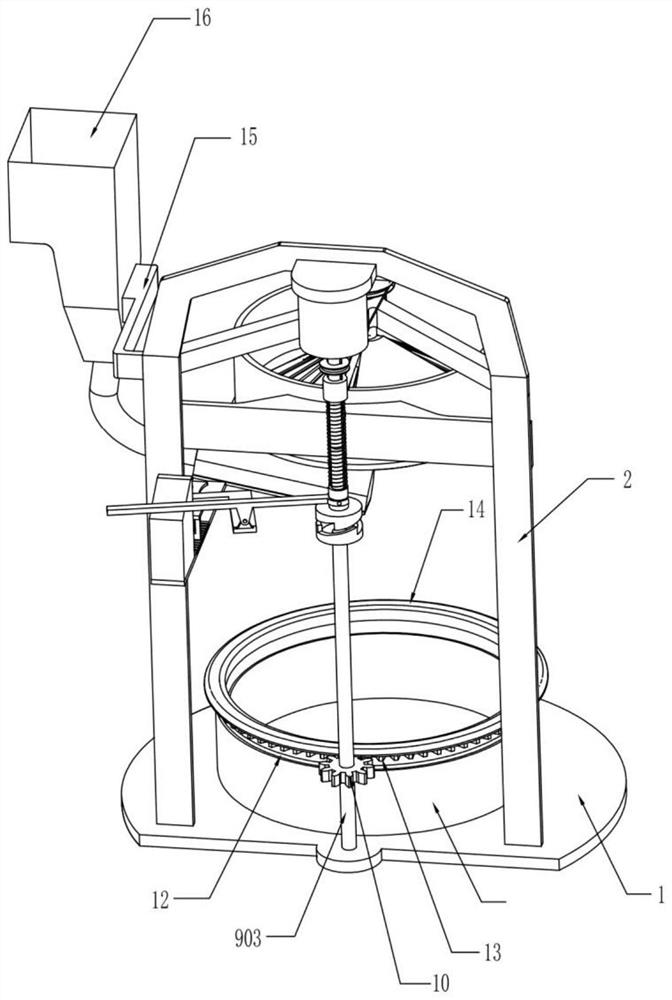

[0025] A kind of fermented soya bean making machine with koji material and crushing function, such as Figure 1-9 As shown, include base 1, support 101, crushing mechanism 2, motor 3, transmission shaft 4, small pulley 5, large pulley 6, belt 7, homing spring 8, control transmission mechanism 9 and bacterium spreading mechanism, all A bracket 101 is installed on the horizontally arranged base 1, the crushing mechanism 2 for crushing fermented soya beans and the motor 3 for driving are all installed on the bracket 101, and the transmission shaft 4 is installed on the crushing mechanism through a bearing. On the mechanism 2 and one end of the transmission shaft 4 is connected to the output shaft of the motor 3, the small pulley 5 is installed on the transmission shaft 4 and is located below the motor 3, and the large pulley 6 is installed on the crushing mechanism 2, the The belt 7 is wound around the small pulley 5 and the large pulley 6, one end of the return spring 8 is insta...

Embodiment 2

[0029] A fermented soya bean making machine with the functions of spreading koji and crushing, such as Figure 1-9As shown, include base 1, support 101, crushing mechanism 2, motor 3, transmission shaft 4, small pulley 5, large pulley 6, belt 7, homing spring 8, control transmission mechanism 9 and bacterium spreading mechanism, all A bracket 101 is installed on the horizontally arranged base 1, the crushing mechanism 2 for crushing fermented soya beans and the motor 3 for driving are all installed on the bracket 101, and the transmission shaft 4 is installed on the crushing mechanism through a bearing. On the mechanism 2 and one end of the transmission shaft 4 is connected to the output shaft of the motor 3, the small pulley 5 is installed on the transmission shaft 4 and is located below the motor 3, and the large pulley 6 is installed on the crushing mechanism 2, the The belt 7 is wound around the small pulley 5 and the large pulley 6, one end of the return spring 8 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com