Preparation method of rural experience type light-storing luminescent material

A luminescent material and light storage technology, applied in luminescent coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of easy migration, uneven combination of afterglow luminescent materials and polyurethane coatings, etc., achieve uniform light absorption, increase light storage and luminescence functions The effect of improving the stability and uniformity of particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: A method for preparing a rural experience-type light-storing luminescent material, the preparation method includes the following specific steps:

[0036] Step 1: Mix 16 parts of polyether diol 2000 and 6 parts of polyether triol 3000 into the reactor, and dehydrate for 4 hours at 105°C and 0.1MPa vacuum;

[0037] Step 2: Add 30 parts of acetone solution and 0.01 part of dibutyltin dilaurate solution to the alcohol solution after dehydration, mix, heat to 75°C, add 6 parts of triphenylmethane triisocyanate, and keep warm at 75°C for 2 hours;

[0038] Step 3: After the NCO value in the above solution reaches the theoretical value, add 4 parts of red long-lasting luminescent material CaS:Eu, Dy, and continue the heat preservation reaction for 1.5 hours to obtain a single-component light-storing polyurethane luminescent material.

Embodiment 2

[0039] Embodiment 2: A method for preparing a rural experience-type light-storing luminescent material, the preparation method includes the following specific steps:

[0040] Step 1: Mix 12 parts of polyether diol 2000 and 4 parts of polyether triol 3000 into the reactor, and dehydrate for 3.5 hours at 103°C and 0.05MPa vacuum;

[0041] Step 2: Add 20 parts of acetone solution and 0.01 part of dibutyltin dilaurate solution to the dehydrated alcohol solution, mix, heat to 70°C, add 4 parts of triphenylmethane triisocyanate, and keep the reaction at 70°C for 1.5h ;

[0042] Step 3: Add 2 parts of red long-lasting luminescent material CaS:Eu,Dy to the above catalytic reaction, and continue the heat preservation reaction for 0.8h to obtain a single-component light-storing polyurethane luminescent material.

Embodiment 3

[0043] Embodiment 3: A method for preparing a rural experience-type light-storing luminescent material, the preparation method includes the following specific steps:

[0044] Step 1: Mix 20 parts of polyether diol 2000 and 8 parts of polyether triol 3000 into the reactor, and dehydrate for 4.5 hours at 108°C and 0.2MPa vacuum;

[0045] Step 2: Add 35 parts of acetone solution and 0.1 part of dibutyltin dilaurate solution to the dehydrated alcohol solution, mix, heat to 78°C, add 8 parts of triphenylmethane triisocyanate, and keep the reaction at 78°C for 2 hours;

[0046] Step 3: Add 6 parts of red long-lasting luminescent material CaS:Eu,Dy to the above catalytic reaction, and continue the heat preservation reaction for 1.8 hours to obtain a single-component light-storing polyurethane luminescent material.

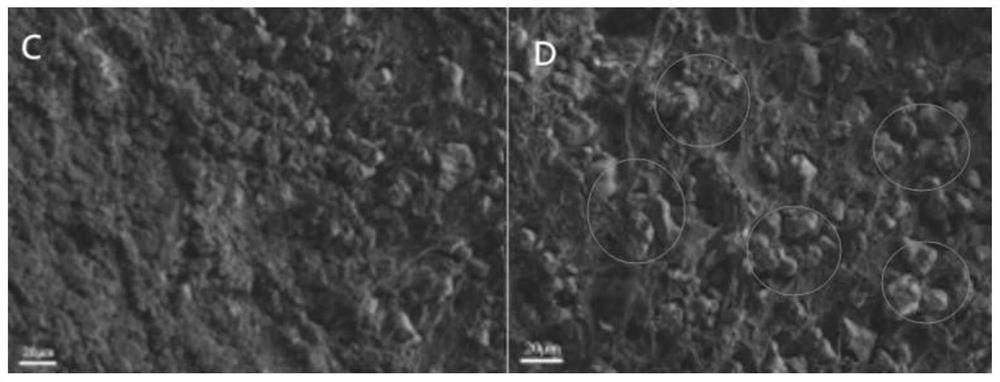

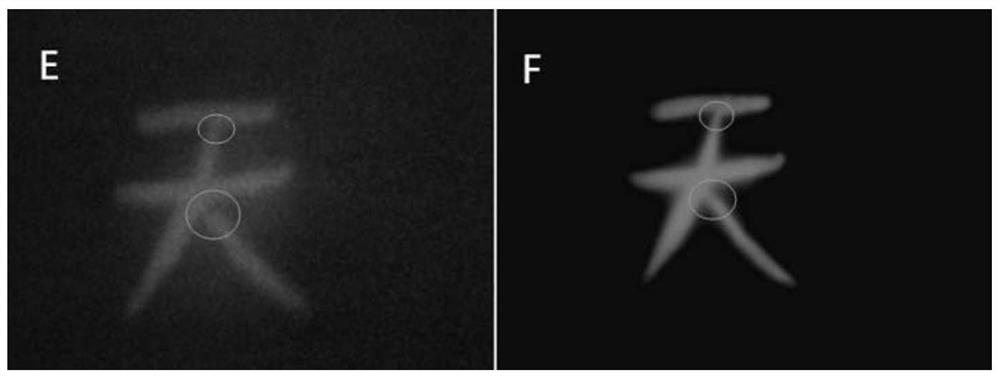

[0047] Comparing the single-component light-storage polyurethane luminescent material prepared in the optimal implementation 1 with the conventional luminescent polyurethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com