Device for detecting packet shortage of cigarette cartons

A technology for detection strips and strip boxes, which is applied in the field of detection systems and can solve problems such as the inability of detectors to detect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

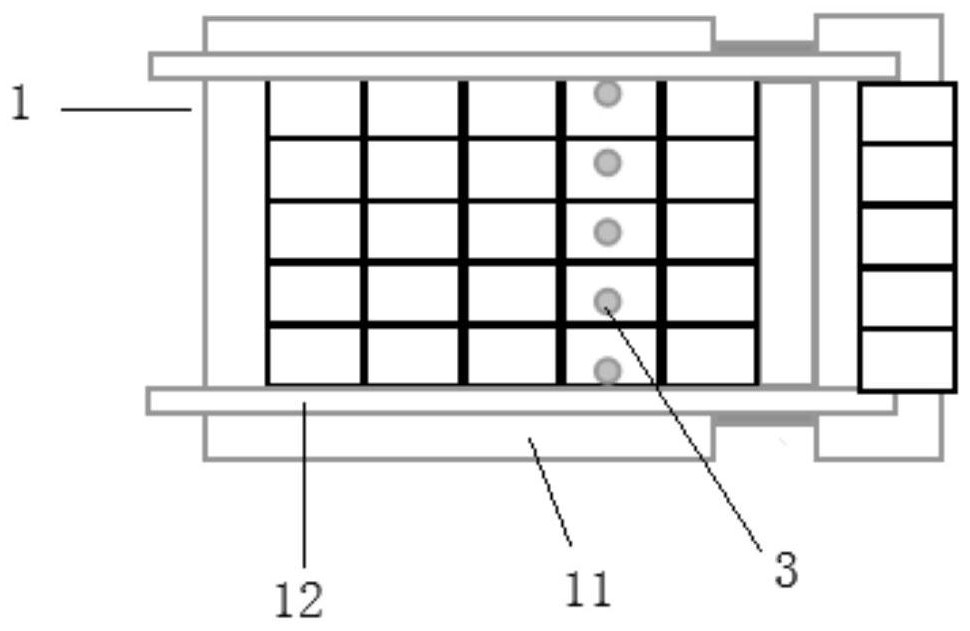

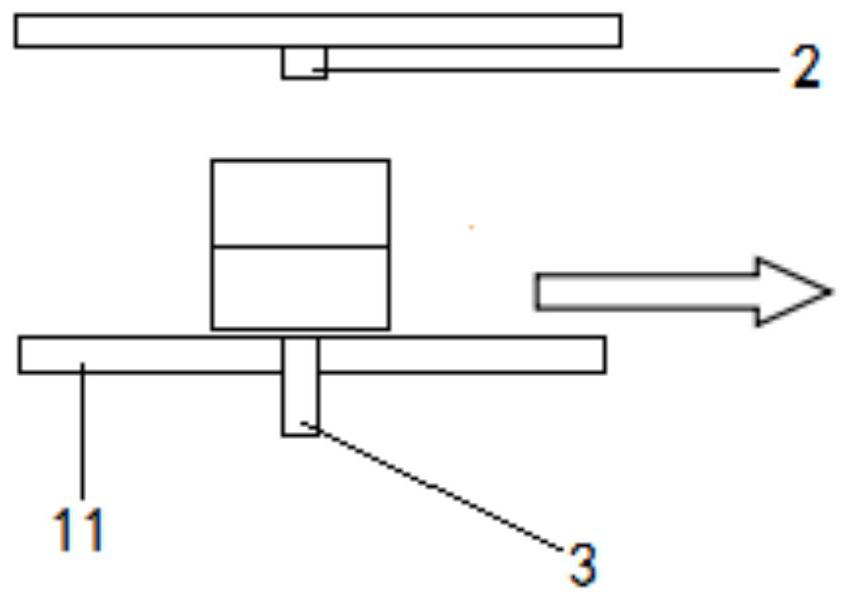

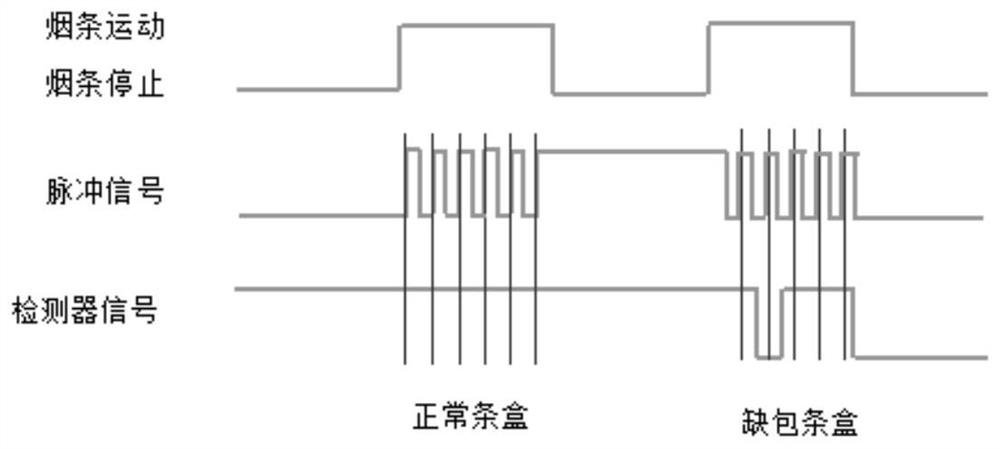

[0030] Such as figure 1 , figure 2 and image 3 As shown, a device for detecting the lack of package in the barrel, including the barrel transmission mechanism 1 installed on the barrel packaging machine, the pulse generation mechanism 2, the switch detection mechanism 3, the pulse generation mechanism 2, the switch detection mechanism 3 are all set on the barrel transmission mechanism 1, the pulse generating mechanism 2 generates continuous pulses and emits them to the barrel, and the switch detection mechanism 3 corresponds to several pulses from the start phase to the end phase of the barrel The signal is detected. In the pulse signal interval, if the signal is low, it will be displayed as missing packets.

[0031] In the above solution, the detection method of electrical scanning is adopted, and the device is used to detect the cigarette packs under the carton, and the cigarette packs in the lower layer of the carton passing through the packaging machine are detected th...

Embodiment 2

[0042] The present invention mainly adopts the detection mode of electrical scanning, and mainly consists of a pulse generation mechanism 2 and a switch detection mechanism 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com