Detection device for high-pressure sealing ring

A technology of high-pressure sealing rings and detection devices, which is applied in the testing of machine sealing rings, by detecting the appearance of fluid at leakage points, and using liquid/vacuum degree for liquid tightness measurement, etc., which can solve the inconvenience of taking and placing sealing rings, making and High maintenance costs and other issues, to achieve the effect of easy access to the sealing ring, low production and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

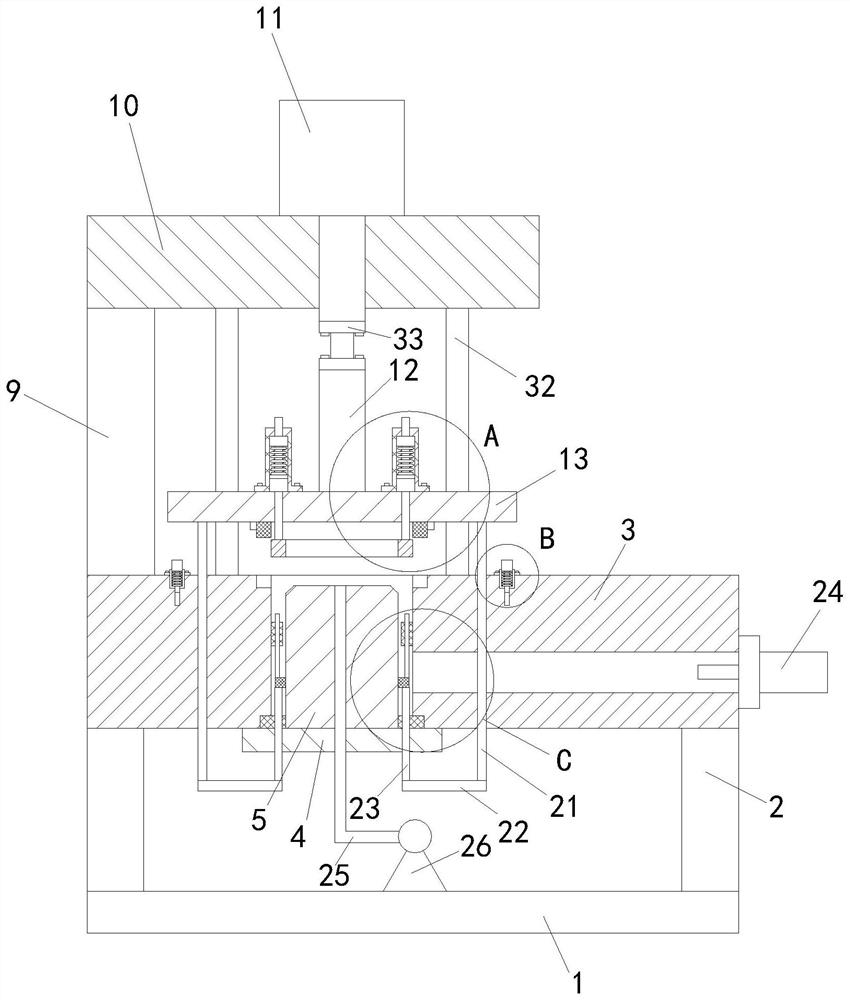

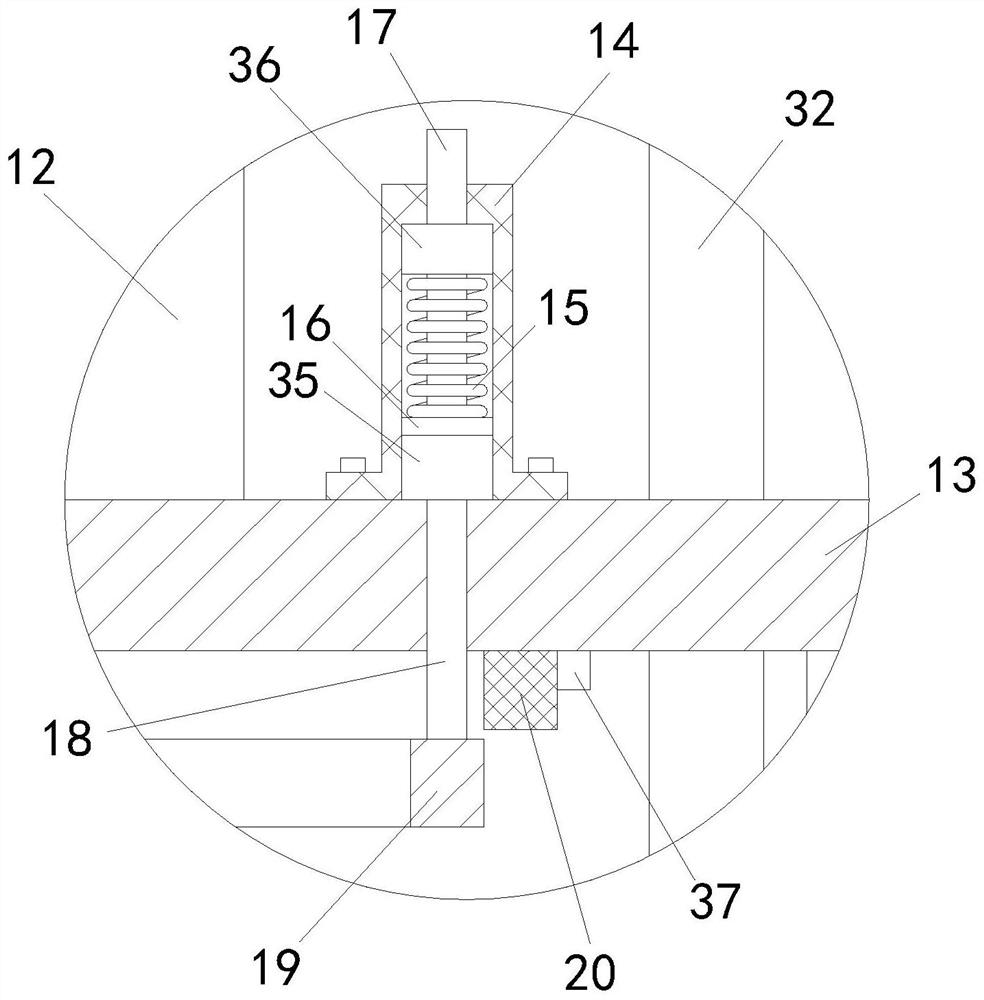

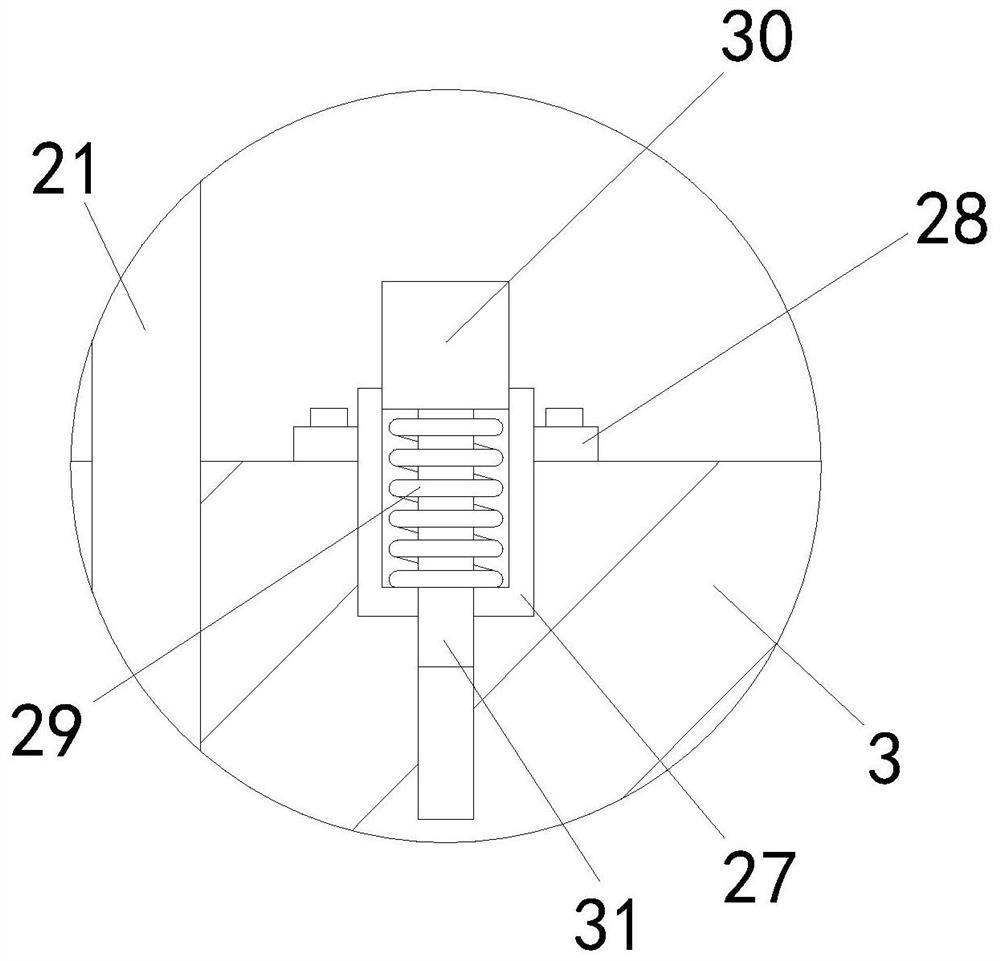

[0028] see Figure 1-7, a detection device for a high-pressure sealing ring, comprising a base plate 1, the top left part and the top right part of the base plate 1 are fixedly connected with a heightening plate 2, the upper side of the base plate 1 is provided with an adapter seat 3, and the bottom of the adapter seat 3 The left part of the end and the right part of the bottom end are all fixedly connected to the top of each corresponding heightening plate 2, the middle part of the adapter seat 3 is provided with an accommodating cavity that penetrates up and down, and the middle part of the bottom end of the adapter seat 3 is fixedly connected with a support plate 4, A sealing strip 34 is provided at the contact between the bottom middle of the adapter seat 3 and the top of the support plate 4, and the sealing strip 34 is a rubber strip; the sealing effect of the sealing strip 34 reduces the leakage of gas from the bottom of the adapter seat 3 , to achieve the effect of furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com