Self-relieving adjustable buffer gas booster cylinder

A technology of buffer gas and pressurized cylinder, which is applied in the direction of liquid variable displacement machinery, fluid pressure actuating device, piston pump, etc., can solve the problems of unsatisfactory vibration and noise reduction effects, so as to improve the service life and reduce the overall operation Vibration and noise, reducing the effect of hydraulic reversing shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0028] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

[0029] It should be understood that terms such as "first" and "second" used herein do not have absolute meanings.

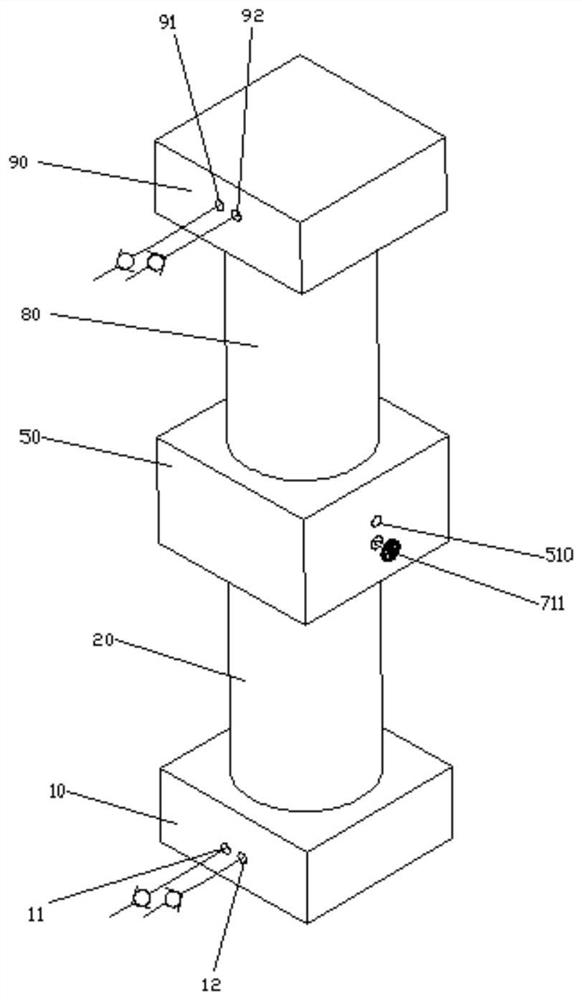

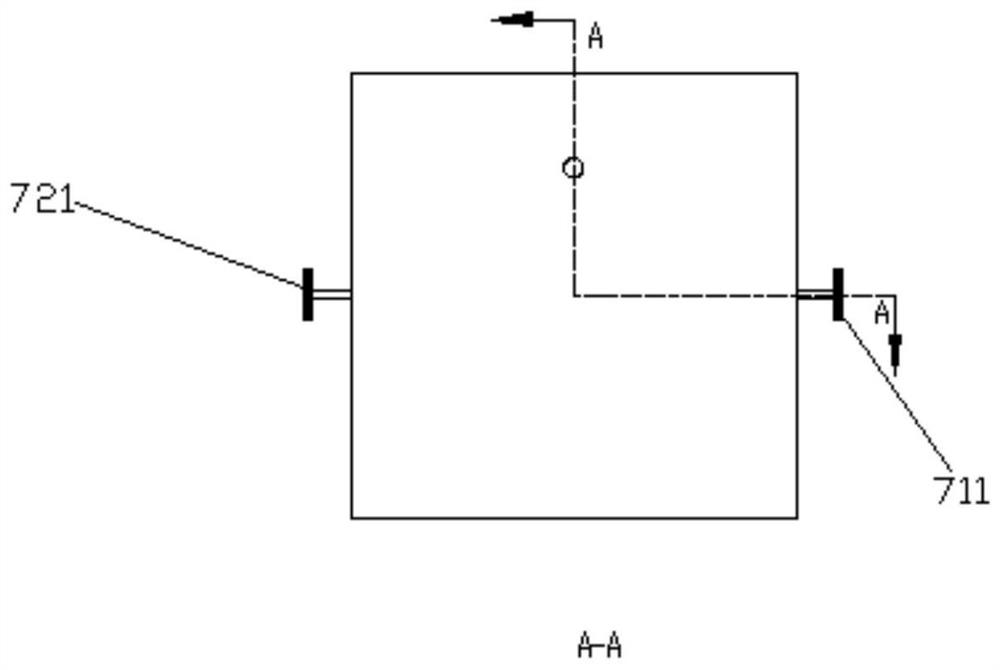

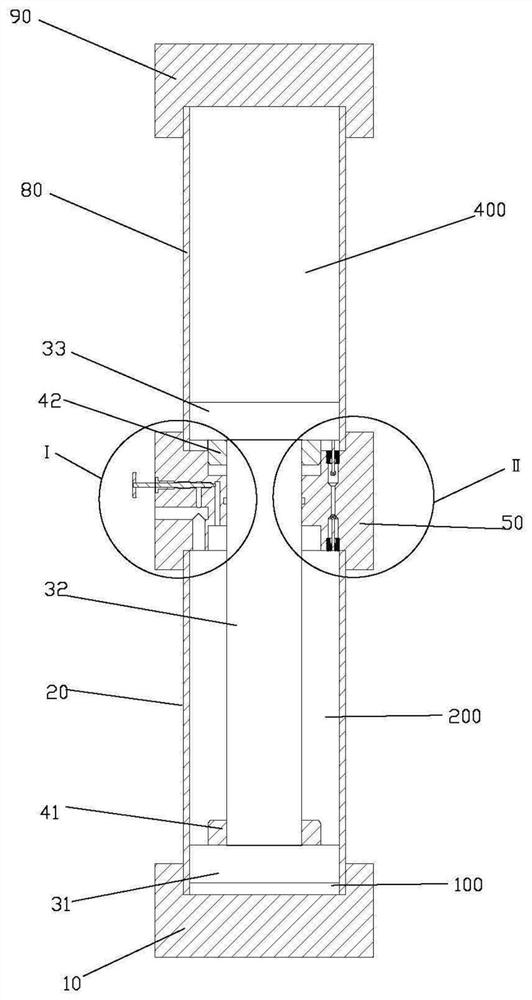

[0030] Please refer to Figure 1-5 , a self-relieving adjustable buffer gas booster cylinder provided by the present invention includes a first cylinder 20 and a second cylinder 80, the first cylinder 20 and the second cylinder 80 are coaxial inside and installed with A slidable piston mechanism comprising a piston rod 32 and a piston coaxially mounted at its two ends, named as a first piston 31 and a second piston 33; the first cylinder 20 has a rod cavity and a second cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com