Well control logging cable hanger and tool component and using method thereof

A hanger and cable technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of inability to implement drilling and sealing measures under the drill pipe and drilling tool, long time consumption, high strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions claimed in the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings.

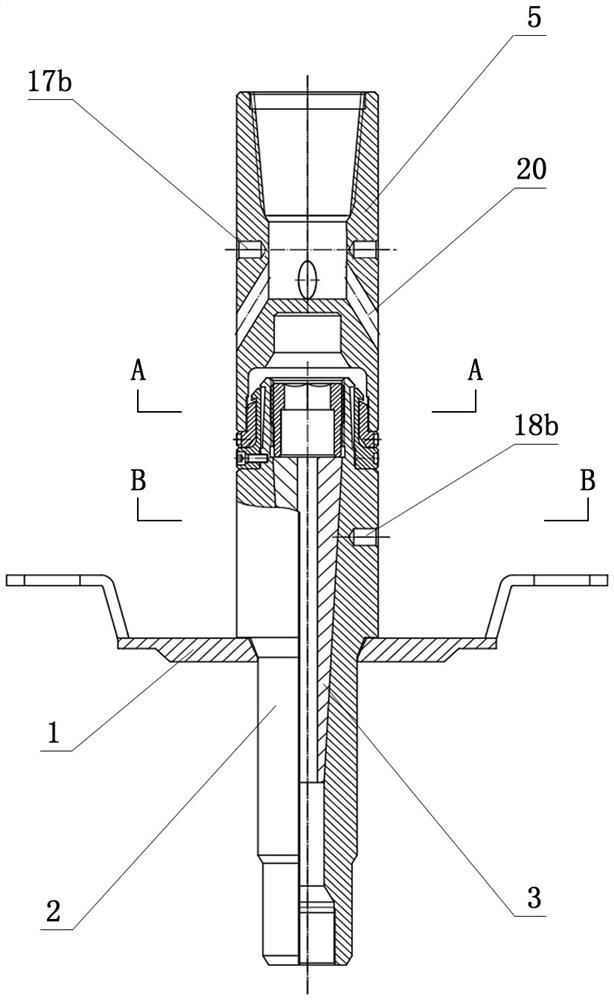

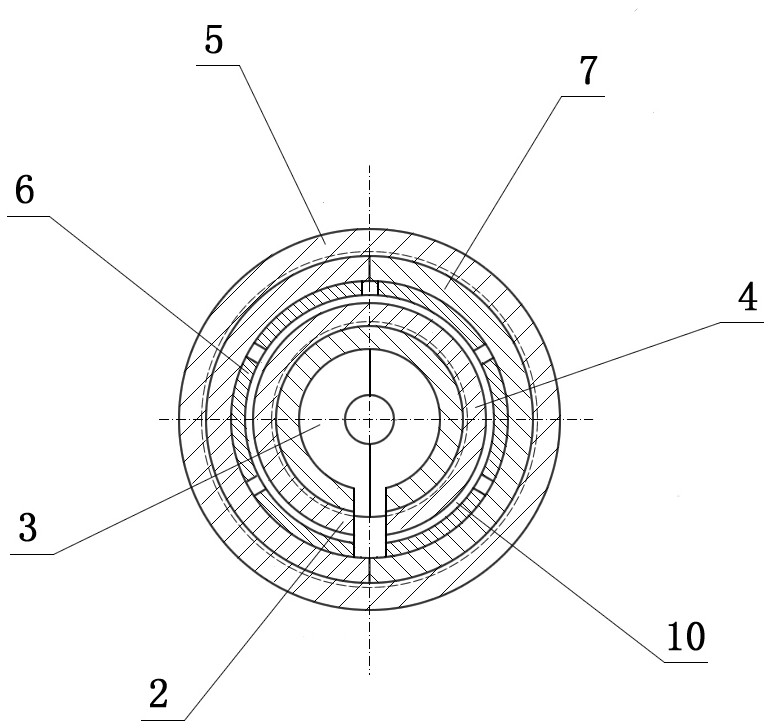

[0029] A well control and logging cable hanger with a quick connection mechanism for drilling tools, such as figure 1 and figure 2 As shown, it is composed of a wellhead chuck 1, a suspension main body 2, split slips 3, slip pressure sleeves 4, double female joints 5, elastic threaded rings 6 and split stop rings 7.

[0030] The wellhead chuck 1 is a square plate, such as Figure 5As shown, a circular hole 11a and a chuck cable introduction groove 11b are opened on the surface of the disk, and a carrying handle 19 is also installed at the same time. Cavity, a cylindrical inner cavity of a certain length is set in the lower part of the conical cavity, the lower end is provided with internal threads, and the side wall is also provided with a main cable introduction groove 13 that runs through the axial direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com