Method for reducing negative pressure at bottom of plane gate and plane gate structure thereof

A plane gate and negative pressure technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems that the gate cannot be closed due to moving water, it is difficult to find air replenishment measures, and the gate is difficult to open and close, so as to achieve processing and transformation Simple, reduce the opening and closing force, and the effect of smooth operation of the gate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

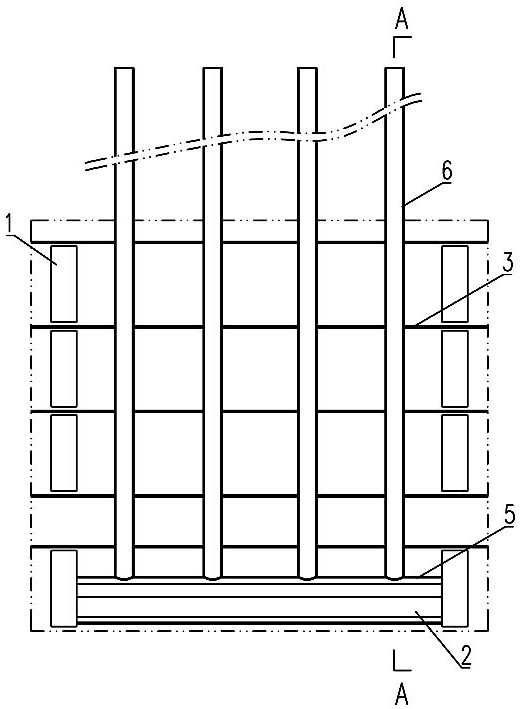

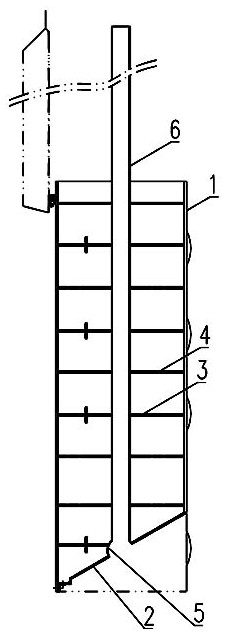

[0017] Such as figure 1 , 2 As shown, the method for reducing the negative pressure at the bottom of the plane gate according to the present invention comprises the following steps:

[0018] Step 1, the lower part of the sand-retaining plane gate is set as a double-panel box-type door leaf 1, and the height of the double-panel box-type door leaf 1 is higher than that of the upper and downstream sides of the double-panel box-type door leaf 1. The viscous force of sediment around the panel box-type door leaf 1; the bottom edge sealing plate 2 of the double-panel bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com