Garbage sweeping mechanical structure based on low-carbon environment-friendly sweeper

A low-carbon, environmentally friendly, mechanical structure technology, applied in cleaning methods, road surface cleaning, dispersed particle filtration, etc., can solve the problems of inability to judge filter element replacement, low practicability, cumbersome steps, etc., to improve practicability and flexibility, The effect of flexible operation and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

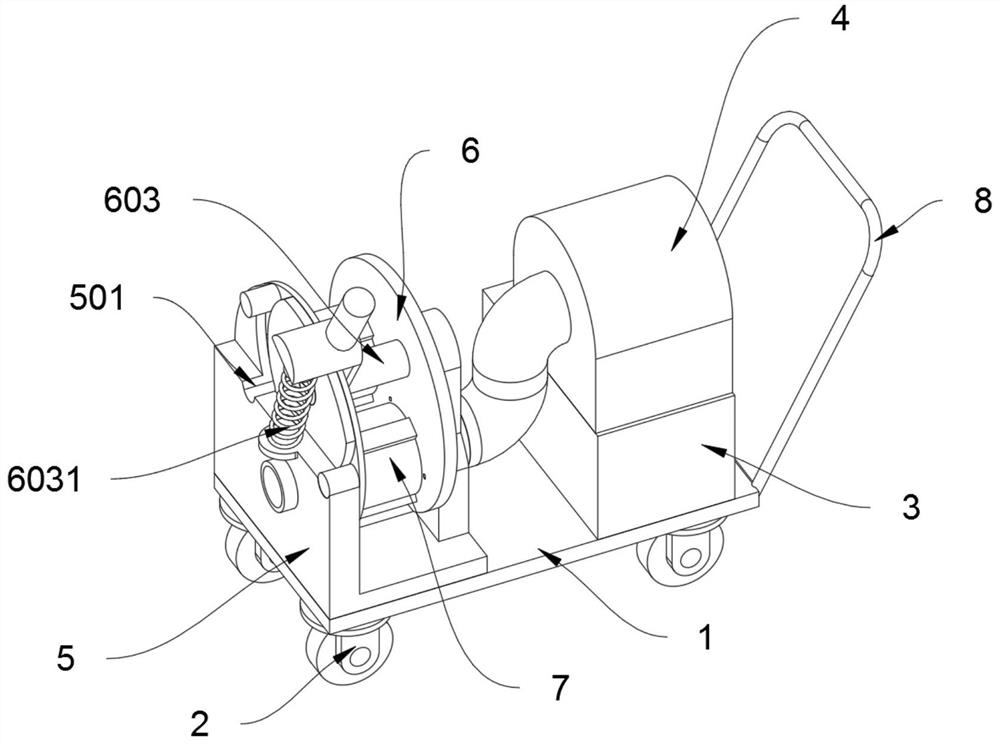

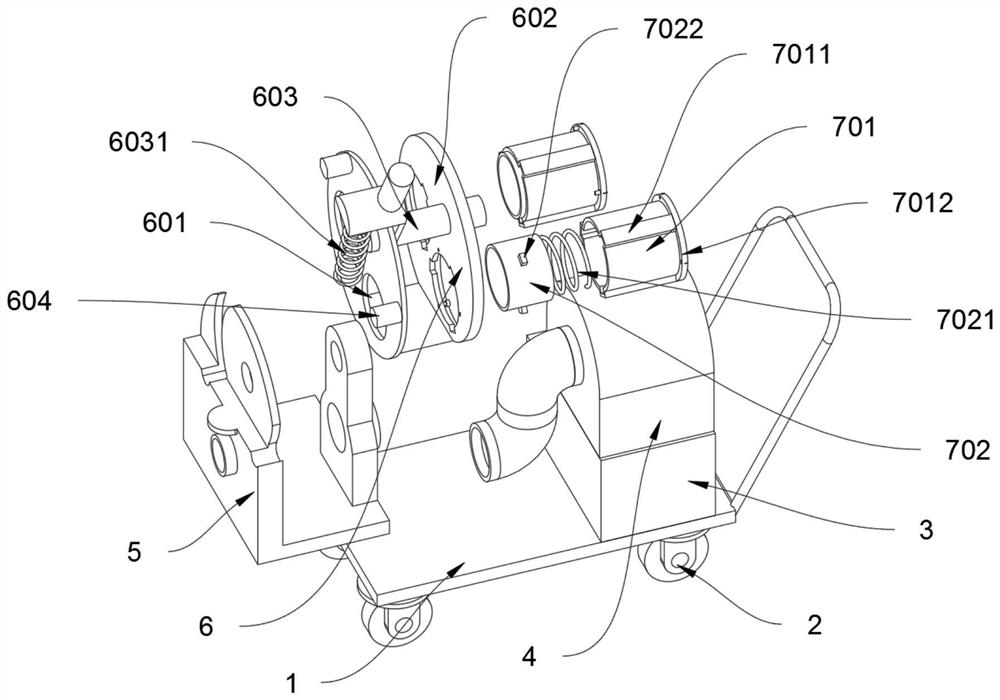

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036] The invention provides a garbage cleaning mechanical structure based on a low-carbon environmental protection cleaning vehicle, including a cleaning platform 1, a moving wheel 2, a battery box 3, a fan pump 4, a fixed casing 5, a replacement bracket 6 and a filter element mechanism 7; The side is fixedly connected with a push-pull handrail 8; the moving wheel 2 is fixedly connected to the bottom surface of the cleaning platform 1; the inside of the battery box 3 is provided with a battery pack, and the battery box 3 is screwed and fixed on the top surface of the cleaning platform 1; the fan pump 4 It is screwed and fixed on the top of the battery box 3, and the fan pump 4 is electrically connected to the battery pack inside the battery box 3 and the external control device. Its specific structure and working principle are prior art, and will not be repeated here. The fixed shell 5 is screwed and fixed on one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com