Tile sticking robot system

A robot system and tiling technology, which is applied in manipulators, program-controlled manipulators, construction, etc., can solve problems such as uneven product quality, high labor costs, and low work efficiency, so as to improve construction efficiency, shorten construction period, and save labor cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

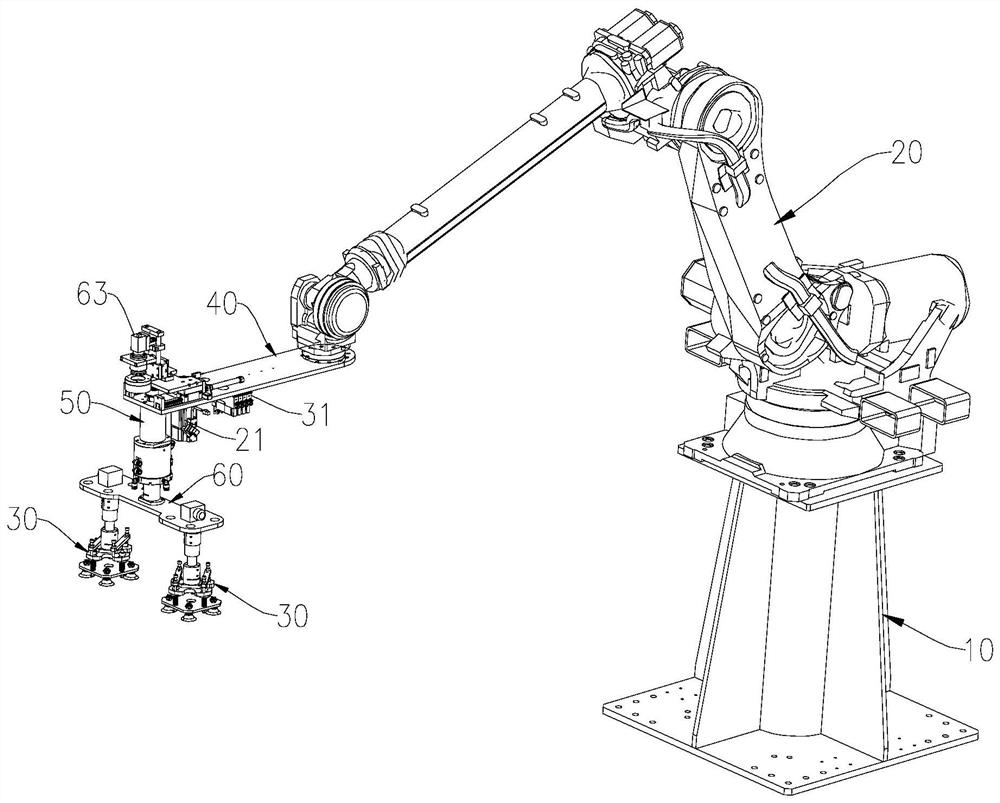

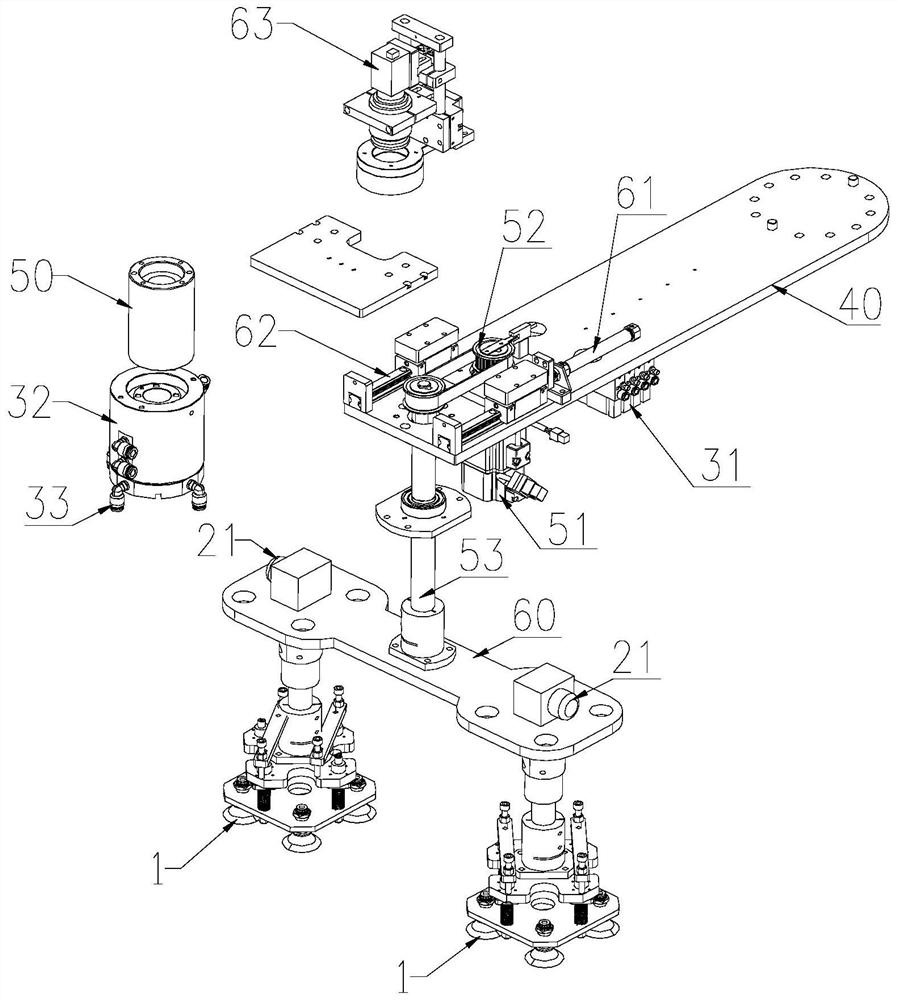

[0026] See figure 1 and figure 2 , shows Embodiment 1 provided by the present invention, a tile laying robot system, which includes a robot base 10, a six-axis robot 20, a manipulator and a controller. The manipulator includes a suction cup gripper 30 , a detector for detecting whether there are tiles, a horizontally extended arm 40 and a vertically elevated arm 50 . The six-axis robot 20 is fixed on the robot base 10, one end of the extended arm 40 is fixed on the power output end of the six-axis robot 20, the other end of the extended arm 40 is connected to the top of the raised arm 50, and the suction cup gripper 30 is installed on the extended arm 40. The bottom end of the high arm 50.

[0027] Among them, see image 3 and image 3 , the suction cup gripper 30 includes a vacuum suction cup 1, a vacuum generator system, a telescoping mechanism and a buffer mechanism.

[0028] The above-mentioned vacuum generator system includes a vacuum generator 31 , an air guide sli...

Embodiment 2

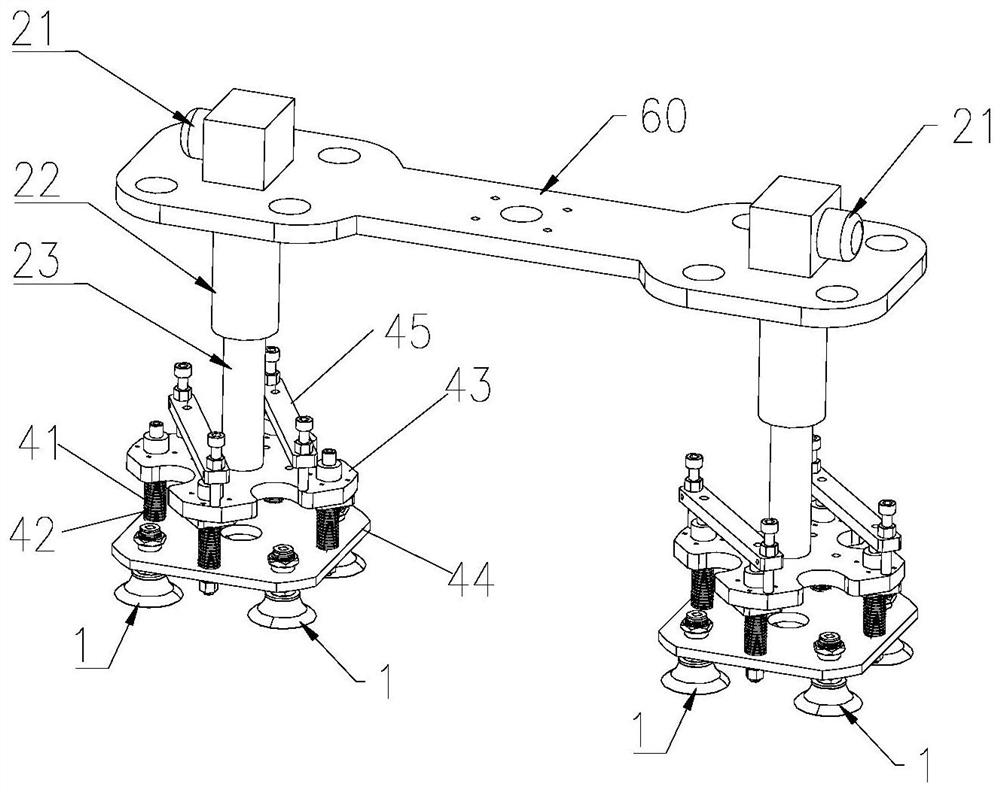

[0042] See Figure 6 and Figure 7 , shows a robot system for tiling tiles provided in this embodiment, which differs from Embodiment 1 in that:

[0043] The manipulator of the tiling robot system in this embodiment includes an extension arm 40 and two suction cup grippers 30, one end of the extension arm 40 is used to connect with the six-axis robot 20, and the two sides of the other end of the extension arm 40 are respectively A suction cup gripper 30 is installed.

[0044] The suction cup gripper 30 also includes an extension rod 5, the length direction of the extension rods 5 on both sides is perpendicular to the length direction of the extension arm 40, one end of the extension rod 5 is fixedly connected with the extension arm 40, and the other end is connected with the extension arm 40. The vacuum chuck 1 is fixedly connected.

[0045] The tiling robot system of this embodiment has two suction cup grippers 30, which can grab two tiles 200 in one reciprocating movement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com