Fabricated mounting structure for special-shaped box section parts

An installation structure and prefabricated technology, which is applied in the direction of building construction and construction, can solve the problems of inharmonious decoration effect, rough installation and fixing form, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

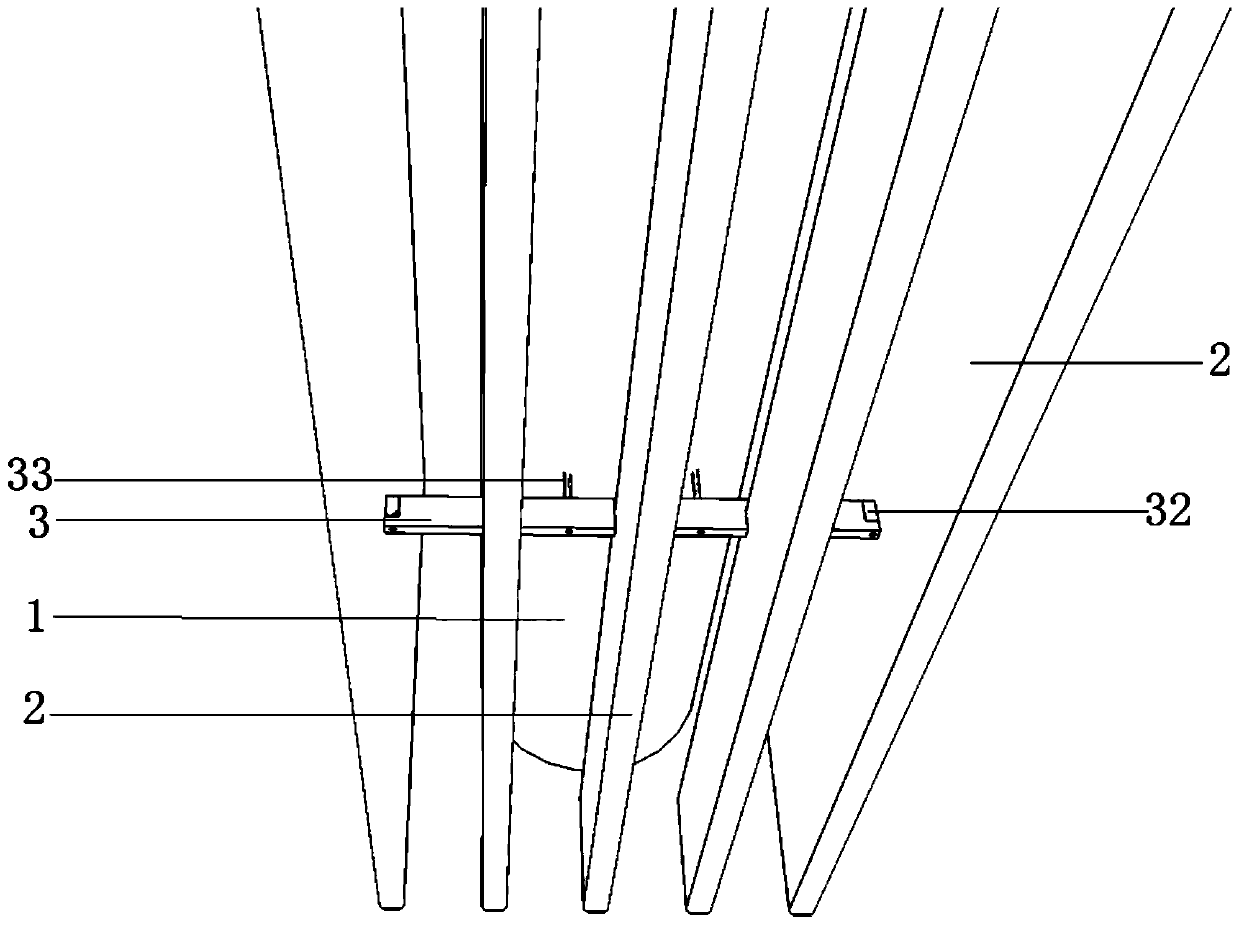

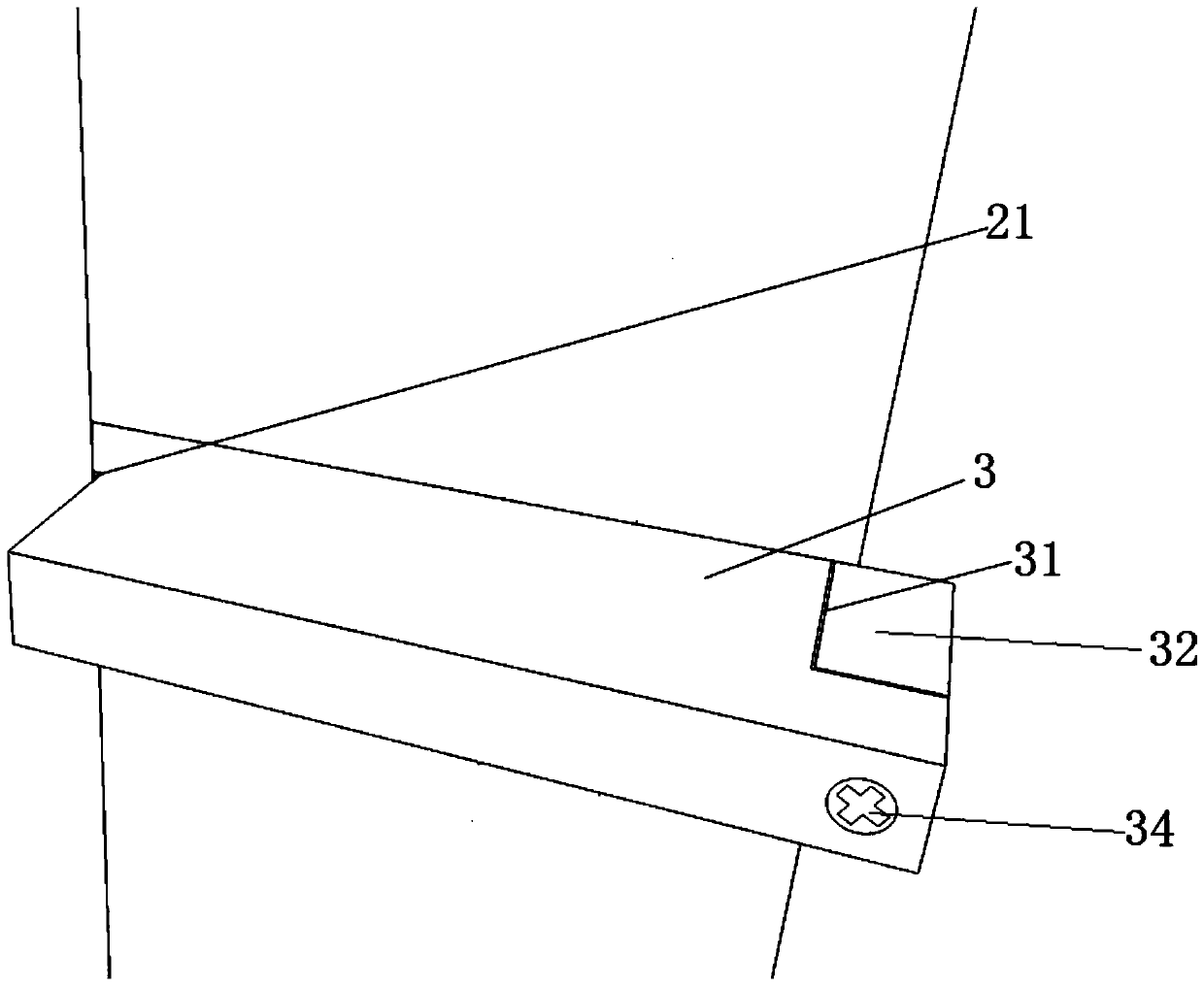

[0026] see Figure 1 to Figure 3 , the figure shows that in the assembled installation structure of a special-shaped square tube provided by Embodiment 1 of the present invention, there are multiple aluminum square tubes 2 and a connecting pipe 3, and the multiple aluminum square tubes 2 are parallel to the base column 1 is arranged in the axial direction, one end of the length direction of the square piece 2 extends to the ground, and the opposite end forms an arc segment and extends to the top surface of the wall, the connecting pipe 3 is a square pipe, and one end of the connecting pipe 3 in the width direction There is a bayonet 21 on the side, and the side of the square piece 2 is stuck in the bayonet 21. The two square pieces 2 located outside the two ends of the connecting pipe 3 are connected to the connecting pipe 3 through the connecting block 32, specifically the connecting pipe 3 There is a notch 31 on the end of the notch, and the notch 31 is a rectangular notch, ...

Embodiment 2

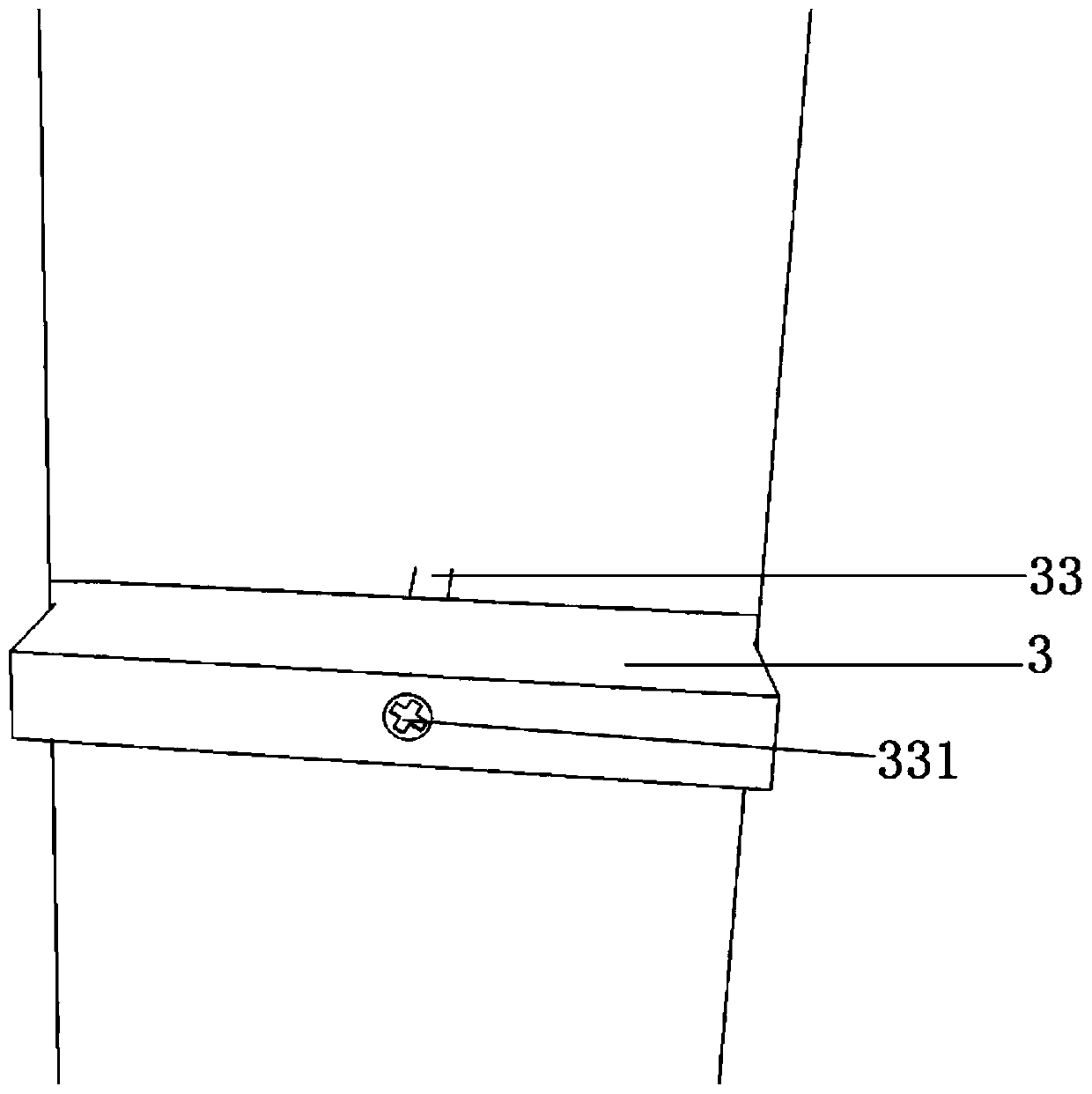

[0037] see Figure 1 to Figure 3 , the figure shows a special-shaped profile installation structure applied to prefabricated decoration provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: Two connecting posts 33 are installed on the connecting pipe 3, the connecting posts 33 pass through the connecting pipe 3 along the width direction of the connecting pipe 3, the ends of the connecting posts 33 are fixedly connected to the surface of the base post 1, and the connecting posts 33 are cylinders, The first screw 331 passes through the connecting tube 3 and is inserted into the connecting post 33 .

[0038] Through the setting of the above structure, the installation and cooperation of the connecting column, the above-mentioned notch and the connecting block can ensure the stability of the horizontal and vertical sides of the square, and can achieve the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com