Production technology and special equipment of a new type of metal photo

A technology of metal photo and special equipment, which is applied in the printing process, printing of special varieties of printed matter, printing, etc., can solve the problems of high scrap rate and high cost of plate making, and achieve the effect of not being afraid of blisters, good shape design, and good visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

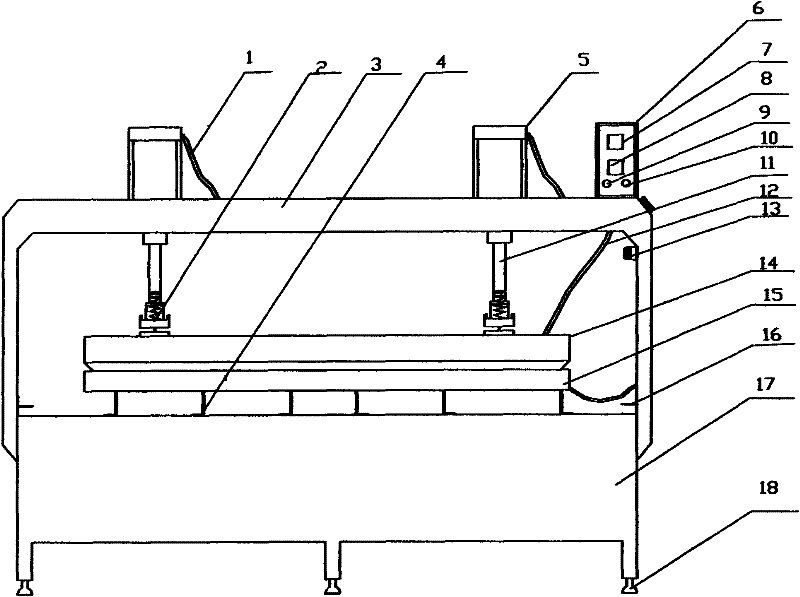

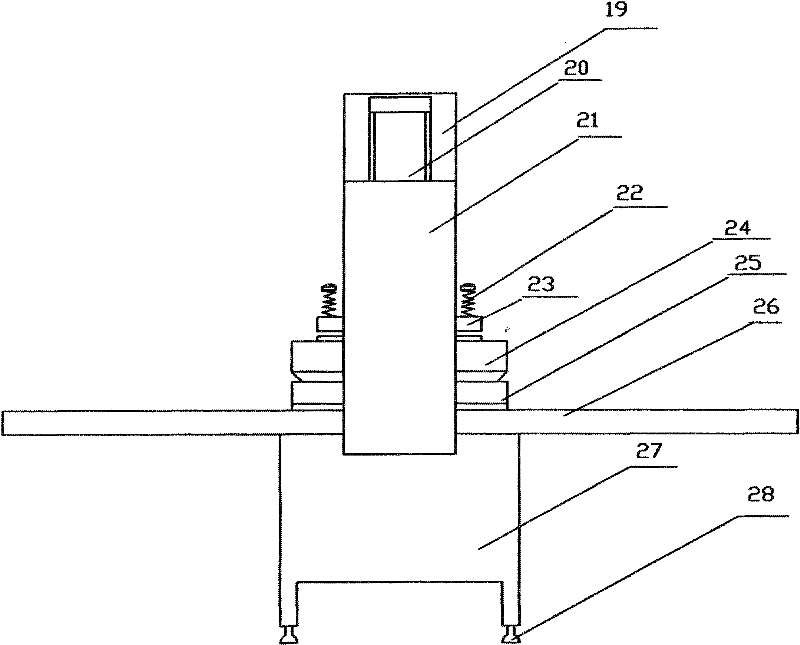

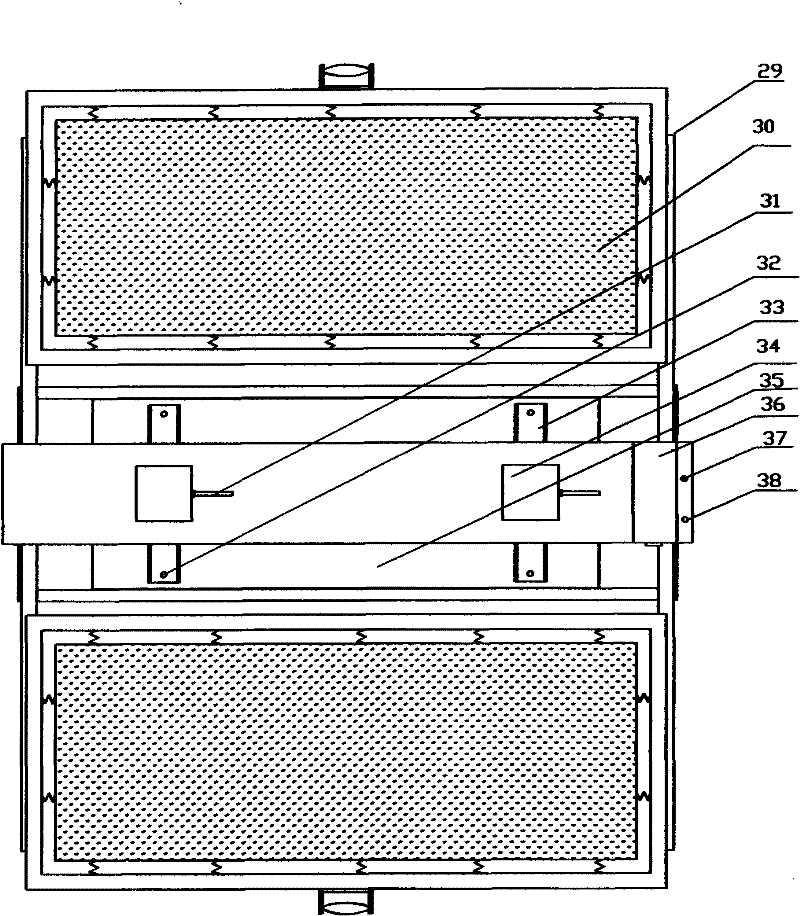

[0021] Embodiment: referring to accompanying drawing 1,2,3,4, the production technology of novel metallic photograph is characterized in that comprising the following steps: a, open external air compressor, to supply enough air pressure to equipment; Generally control at 0.8-1.0 , 1.0-1.2, 1.2-1.5 atmospheric pressure interval grades; b. Power on the equipment and set the required temperature value, generally controlled at 150-180 degrees, 180-200 degrees, 190-220 degrees, 220-260 degrees range; set the time value required for a working cycle; generally controlled at 60-80 seconds, 80-100 seconds, 120-180 seconds, 150-220 seconds interval grade; c, will adjust the size of the image information Input a color printer; d. Print out a color image of a preset size through the printer; e. Reversely paste the printed image paper on a special metal plate of the same size, and select different tones of galvanizing according to the image information of different main colors plate or all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com