Embedding material of sulforaphane and preparation method of embedding material

A technology of sulforaphane and low-methoxyl pectin, applied in food science, application, food ingredients, etc., can solve the challenges of sulforaphane production and storage, and achieve high embedding efficiency and wide adaptability , Improve the effect of embedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

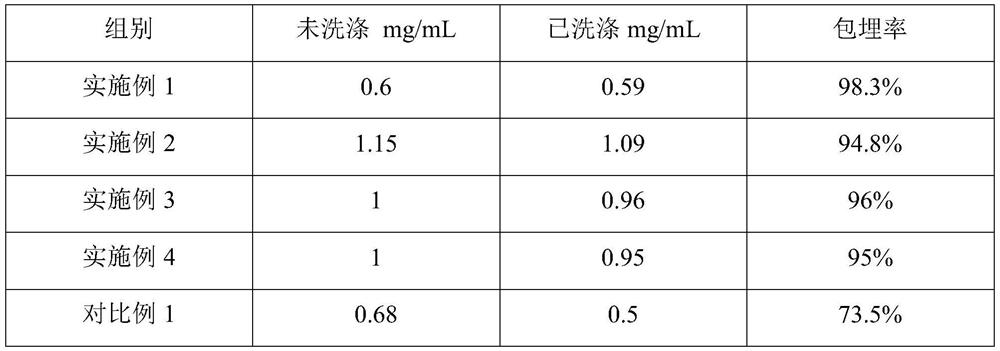

Embodiment 1

[0029] The preparation method of the embedding material of sulforaphane also includes the following steps:

[0030] Step 1. Stir 100g of water, 0.04g of calcium acetate, and 5g of low-methoxyl pectin with a high-speed stirrer, wherein the mass ratio of low-methoxyl pectin to water is 1:20, and the low-methoxyl pectin The mass ratio of glue to calcium acetate is 1:0.008;

[0031] Step 2: Add 2g of pullulan, 0.5g of glutenin, and 0.25g of sucrose fatty acid ester and stir evenly with a high-speed mixer. Among them, low methoxyl pectin, pullulan, glutenin, and sucrose fatty acid ester The mass ratio is 1:0.4:0.1:0.05, and the molecular weight of pullulan is 500,000-700,000 da;

[0032] Step 3: Add 0.35g of sulforaphane and stir evenly with a high-speed stirrer along the same clock direction;

[0033] Step 4: Freeze-drying to obtain sulforaphane embedding powder with a water content of 6%.

Embodiment 2

[0035] The preparation method of the embedding material of sulforaphane also includes the following steps:

[0036] Step 1. Stir 100g of water, 0.08g of calcium acetate, and 4g of low-methoxyl pectin with a high-speed mixer, wherein the mass ratio of low-methoxyl pectin to water is 1:25, and the low-methoxyl pectin The mass ratio of glue to calcium acetate is 1:0.02;

[0037] Step 2: Add 2g of pullulan, 0.8g of glutenin, and 0.4g of sucrose fatty acid ester and stir evenly with a high-speed mixer, wherein, low methoxyl pectin, pullulan, glutenin, and sucrose fatty acid ester The mass ratio of the pullulan is 1:0.5:0.2:0.1, and the molecular weight of pullulan is 500,000-700,000 da;

[0038] Step 3: Add 0.48g sulforaphane and stir evenly with a high-speed stirrer along the same clock direction;

[0039] Step 4: Freeze-drying to obtain sulforaphane embedding powder with a moisture content of 5%.

Embodiment 3

[0041] The preparation method of the embedding material of sulforaphane also includes the following steps:

[0042] Step 1, 100g of water, 0.06g of calcium acetate, and 4.5g of low-methoxy pectin are stirred evenly with a high-speed stirrer;

[0043] Step 2: Add 1.8g of pullulan, 0.5g of glutenin, and 0.3g of sucrose fatty acid ester and stir evenly with a high-speed stirrer. The molecular weight of pullulan is 500,000-700,000 da;

[0044] Step 3: Add 0.4g sulforaphane and stir evenly with a high-speed stirrer along the same clock direction;

[0045] Step 4: Freeze-drying to obtain sulforaphane embedding powder with a moisture content of 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com