Appliance for cable stripping

A technology for cables and appliances, which is applied in the field of electric power maintenance tools, can solve problems such as easily damaged metal wires and complex cable stripping operations, and achieve the effects of labor-saving operation, avoiding damage to metal wires, and easy cutting length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

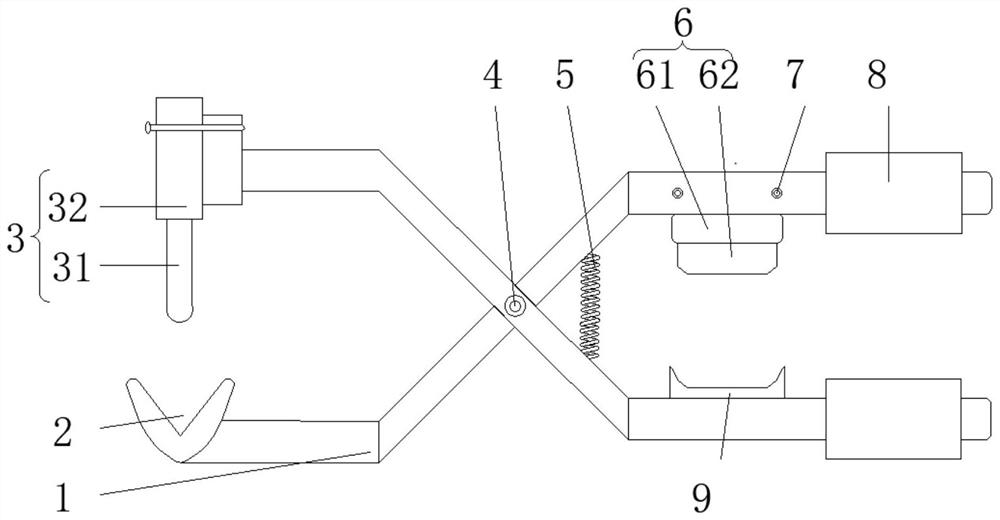

[0029] Such as figure 1 As shown, this embodiment provides an appliance for stripping cables, including a first support member 9 , a first cutting blade 6 , an elastic member 5 and two pliers 1 . The two pliers bodies 1 are hinged, and one end of the pliers body 1 forms a pliers head, and the other end forms a pliers handle. The inner side of one of the two pliers 1 is provided with a first support 9, and the other of the two pliers 1 is provided with a height-adjustable first cutting blade 6 corresponding to the position of the first support 9, And the first cutting blade 6 can cut the outer insulating layer of the cable along the radial direction of the cable. The elastic member 5 elastically connects the two pliers handles, and the elastic member 5 can drive the two pliers handles away from each other.

[0030] When cutting the cable, hold the two pliers handles tightly, the first cutting blade 6 and the first support member 9 will approach each other, make the first cutt...

Embodiment 2

[0052] This embodiment provides an appliance for stripping cables, which is further improved on the basis of Embodiment 1 to adjust the distance between the blade and the centerline of the support.

[0053] Specifically, the tool for stripping cables further includes spacers, which can be selectively arranged between the cutting blade and the pliers body 1 . Taking the second cutting blade 3 as an example, gaskets can be set between the second cutting blade 3 and the pliers body 1 according to specific needs, and the number of gaskets and the thickness of each gasket can be selected as required, thereby adjusting the second cutting blade 3. The relative position of the cutting blade 3 and the second supporting member 2, for example, can be such that the second cutting blade 3 can be located directly above the center line of the second bearing groove, or can be located on one side of the center line of the second bearing groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com