Profinet protocol-based communication method for intelligent equipment and peripheral device

A technology for peripheral devices and intelligent equipment, applied in the direction of instruments, general control systems, comprehensive factory control, etc., can solve the problems of high cost, unstable signal, and difficult data acquisition at the bottom of the equipment, and achieve speed improvement, data information volume and width. Extended, convenient signal processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The communication method of the present invention is used for the communication between the CNC machine tool and the sensor, including the collection of sensor data information and the collection of analog information, such as figure 1 As shown, the specific steps are as follows:

[0059] Step M1: According to the design requirements, configure the relevant system software and hardware requirements;

[0060] Design requirements: collect the value of the temperature sensor (PT1000) inside the Kessler electric spindle into the CNC machine tool system, and display the temperature value on the HMI interface.

[0061] At the same time, the requirements for the FANUC_31iB CNC system are as follows:

[0062] Hardware configuration requirements:

[0063] A02B-0323-J147 (Fast Ethernet board);

[0064] Software configuration requirements:

[0065] A02B-0323-J564#658R (PROFINET I / O software for 30I / 31I / 32I-B);

[0066] A02B-0327-R971 (31I-B PROFINET IO control function);

[...

specific Embodiment 2

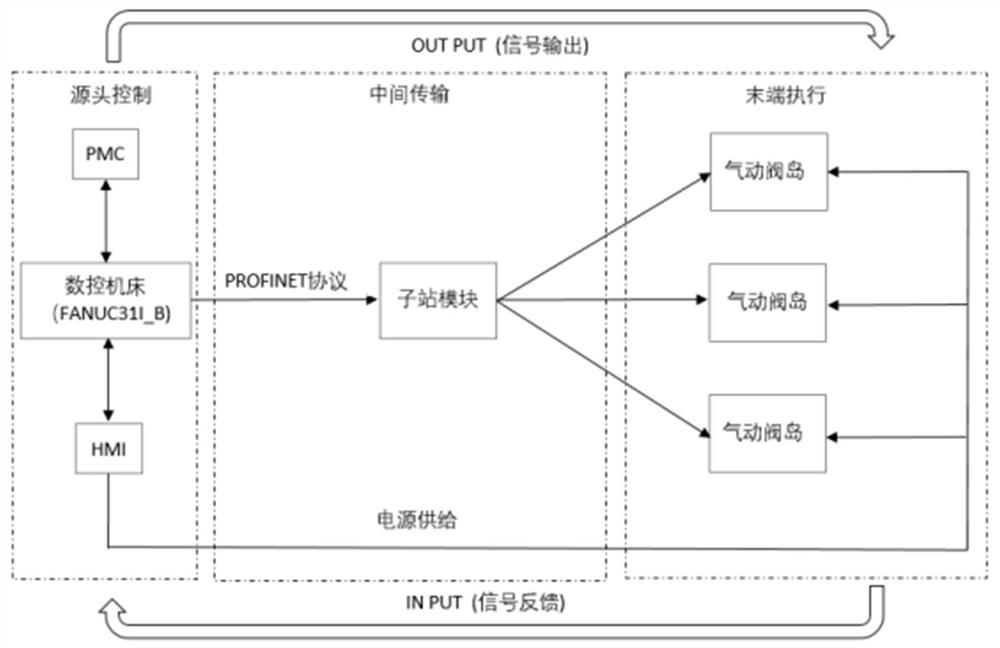

[0084] Apply the communication method of the present invention to the machine tool industry, including the control of CNC machine tools and pneumatic valves, such as figure 2 As shown, the specific steps are as follows:

[0085] Step M1: According to the design requirements, configure the relevant system software and hardware requirements;

[0086] Design requirements: Control the action of the FESTO valve island through the Profinet function of the FANUC CNC system

[0087] At the same time, the requirements for the FANUC_31iB CNC system are as follows:

[0088] Hardware configuration requirements:

[0089] A02B-0323-J147 (Fast Ethernet board);

[0090] Software configuration requirements:

[0091] A02B-0323-J564#658R (PROFINET I / O software for 30I / 31I / 32I-B);

[0092] A02B-0327-R971 (31I-B PROFINET IO control function);

[0093] The system configuration parameters are shown in Table 2:

[0094] Table 2:

[0095] parameter number Parameter Description P...

specific Embodiment 3

[0109] The communication method of the present invention is used for data acquisition and data transmission between smart devices, such as image 3 As shown, the specific steps are as follows:

[0110] Step M1: According to the design requirements, configure the relevant system software and hardware requirements;

[0111]Design requirements: Realize the communication between devices through the Profinet function of smart devices.

[0112] The following requirements are required for smart devices:

[0113] 1. All smart devices need to have the Profinet function;

[0114] 2. It is necessary to add a coupler module: Siemens PN / PN Coupler;

[0115] Specifically, smart devices need to be configured, see the control architecture diagram for details image 3 ;

[0116] Step M2: According to the design requirements, design a table of related configurations;

[0117] Step M3: According to the table in step M2, draw the relevant electrical schematic diagram and complete the wiring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com