Goggles suitable for all-weather wearing and preparation method thereof

A technology of goggles and substrates, applied in the field of goggles, can solve the problems of increasing fatigue, affecting the performance of golfers' skills, and the difference in lens distance, so as to achieve clear and three-dimensional viewing of objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

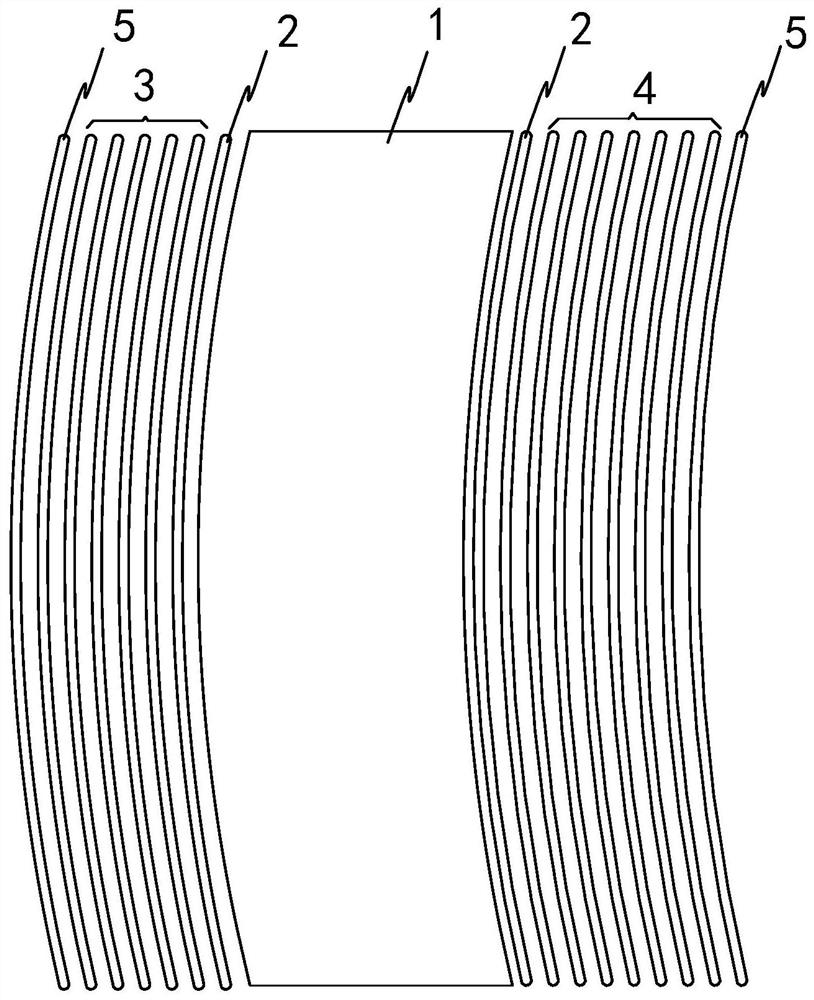

[0034] Please refer to figure 1 , the goggles include a high-reflection film layer and an anti-reflection and anti-reflection film layer, the high-reflection film layer is located on the surface of the substrate away from the eyes, and the anti-reflection and anti-reflection film layer is located on the surface of the substrate near the eyes . A hard coating for improving the hardness and wear resistance of the surface of the substrate is also provided between the high reflection film layer and the substrate, and between the antireflection and antireflection film layer and the substrate. The surface of the high reflection film layer and the surface of the anti-reflection and anti-reflection film layer are also provided with a hydrophobic and oil-repellent layer.

[0035] Wherein, the high reflection film layer is composed of alternately arranged silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com