A heat storage reversing flameless combustion device

A flameless combustion and heat storage technology, applied in the direction of burners, combustion types, combustion methods, etc., can solve problems such as incomplete combustion of burners, many production failures, uneven heating temperature, etc., and achieve reduction of nitrogen oxide emissions, Improve the effect of high combustion efficiency and uniform heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

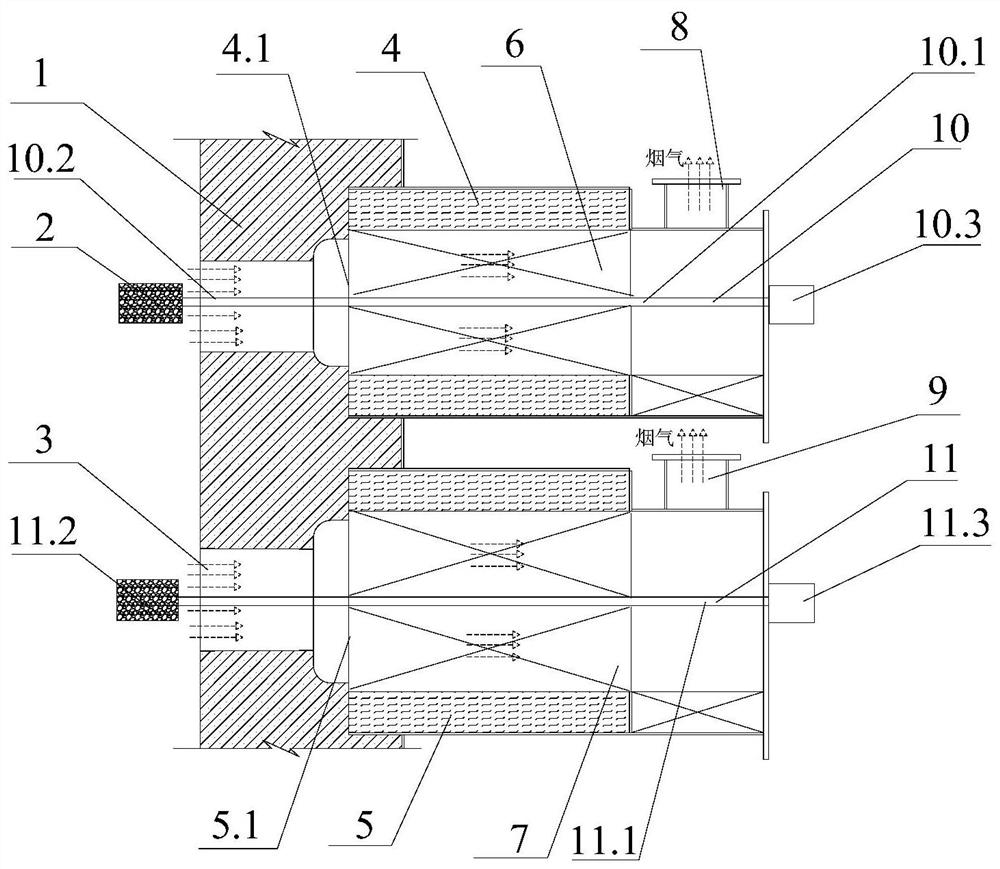

[0038] combine figure 1 and figure 2 As shown, the regenerative reversing flameless combustion device of this embodiment is a blast furnace gas double regenerative type, which specifically includes a burner brick 1, an air nozzle 2, a gas nozzle 3, an air thermal storage tank 4, a gas thermal storage tank 5, Air heat accumulator 6, gas heat accumulator 7, air pipe 8, gas pipe 9, first telescopic mechanism 10, first stretch rod 10.1, first plug 10.2, first two-position telescopic valve head 10.3, second The telescopic mechanism 11, the second stretch rod 11.1, the second plug 11.2, and the second two-position telescopic valve head 11.3.

[0039] The burner brick 1 is provided with two nozzles, the two nozzles are the air nozzle 2 and the gas nozzle 3 respectively. The air nozzle 2 and the gas nozzle 3 are arranged up and down along the height direction of the burner brick 1 .

[0040] An air heat storage chamber 4.1 is set up in the air heat storage box 4 along its axial dir...

Embodiment 2

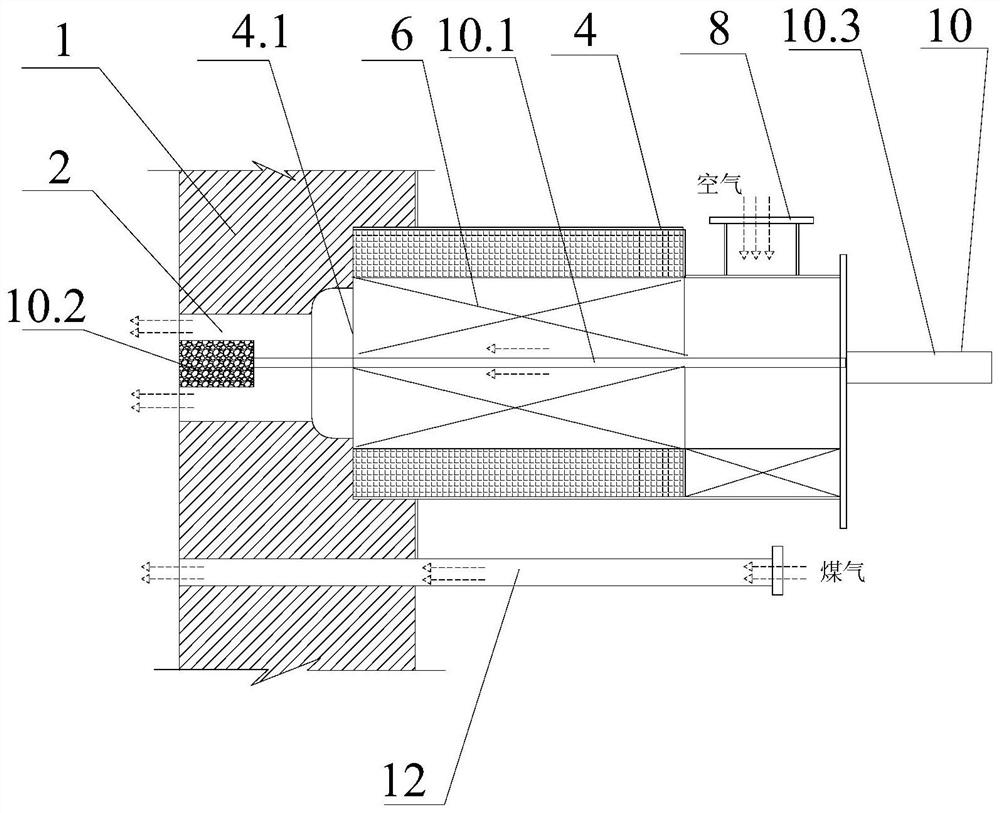

[0047] combine image 3 and Figure 4 As shown, the regenerative reversing flameless combustion device of this embodiment is a single regenerative type of coke oven gas, which specifically includes a burner brick 1, an air nozzle 2, an air regenerator box 4, an air regenerator 6, and an air pipe 8. , The first telescopic mechanism 10 , the first stretching rod 10.1 , the first plug 10.2 , the first two-position telescopic valve head 10.3 , and the first gas straight-through pipe 12 .

[0048] The air nozzle 2 is opened on the upper part of the burner brick 1, the air nozzle 2 extends inward along the outer end surface of the burner brick 1, and the first gas straight pipe 12 is arranged at the lower part of the burner brick 1, along the outer end of the burner brick 1 The face extends inward until it runs through the entire burner block 1 .

[0049] The air heat storage box 4 is provided with an air heat storage chamber 4.1 along its axial direction; an air heat storage body...

Embodiment 3

[0052] combine Figure 5 and Image 6 As shown, the regenerative reversing flameless combustion device in this embodiment is a natural gas single regenerative type, which specifically includes a burner brick 1, an air nozzle 2, an air regenerator 4, an air regenerator 6, an air pipe 8, a A telescopic mechanism 10 , a first stretch rod 10.1 , a first plug 10.2 , a first two-position telescopic valve head 10.3 , and a second gas straight-through pipe 14 .

[0053] The burner brick 1 is provided with an air nozzle 2, the air nozzle 2 extends inward along the outer end face of the burner brick 1, and an air heat storage chamber 4.1 is opened in the air heat storage box 4 along its axial direction; in the air heat storage chamber 4.1 An air heat storage body 6 is installed inside; the air nozzle 2, the air heat storage cavity 4.1 and the air pipe 8 are connected in sequence to form an air circulation passage.

[0054] The second gas straight pipe 14 penetrates through the air cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com