A damping buffer for submersible deployment and recovery operations

A buffer and damping technology, applied in the field of damping buffers, can solve the problems of difficult to meet the high-strength, large-stroke impact environment of manned submersible deployment and recovery, the large impact of hydraulic oil pollution on the marine environment, and the complex structure. Achieve the effect of high stiffness, strong shock absorption capacity, and reduced complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

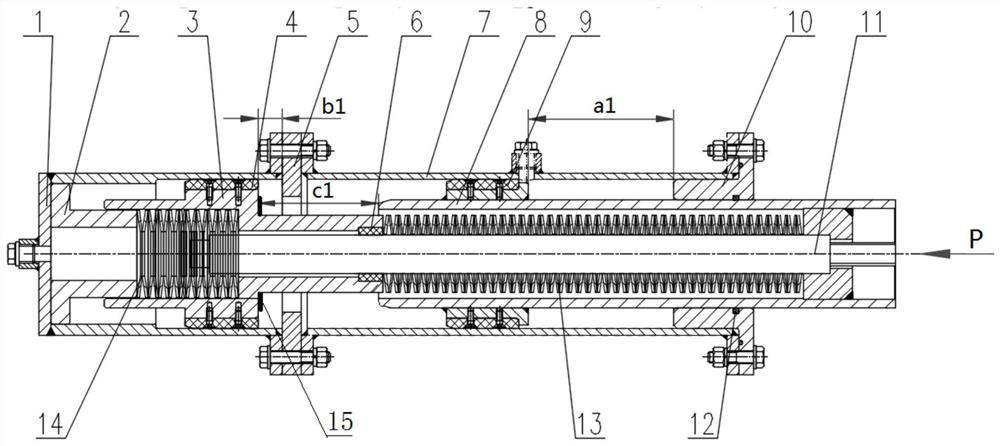

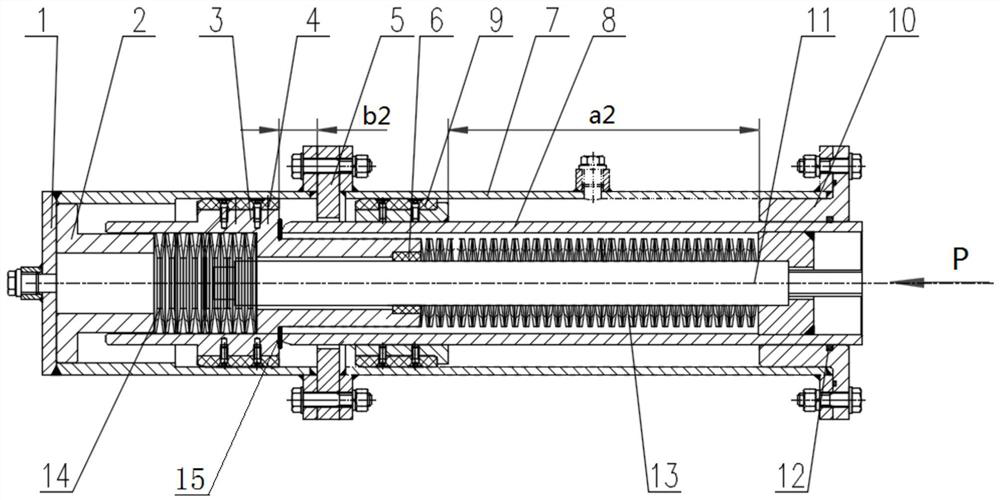

[0029] The specific technical solutions of the present invention are further described in the accompanying drawings of the structural description below.

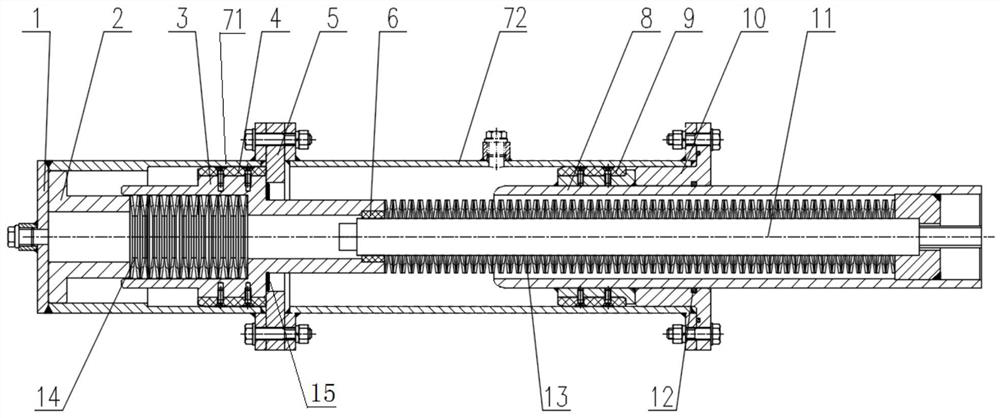

[0030] as attached figure 1 As shown, a damping buffer for submersible deployment and recovery operations of the present invention includes a cylinder head (1), a disc spring washer (2), two disc spring guides (3), and two guide bearings (4) , Stop adjustment washer (5), guide rod bushing (6), cylinder assembly (7), disc spring guide one (8), guide bearing one (9), guide bushing (10), guide rod ( 11), sealing ring (12), disc spring one (13), disc spring two (14) and buffer washer (15).

[0031] The cylinder block 7 and the cylinder head 1 and the guide bushing (10) at its two ends form the buffer damper body, and the cylinder block 7 is formed by butting the left cylinder block 71 and the right cylinder block 72 to support the whole structure. Disc spring washer 2 is a cylindrical structure with a flange at one end, and on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com