Detection device for expressway electromechanical equipment

A technology for electromechanical equipment and highways, applied in mechanical equipment, engines, wind power generation, etc., can solve the problems of reducing the detection accuracy of fan air volume and reducing ventilation volume, and achieve good dustproof effect, good permeability, and improve detection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

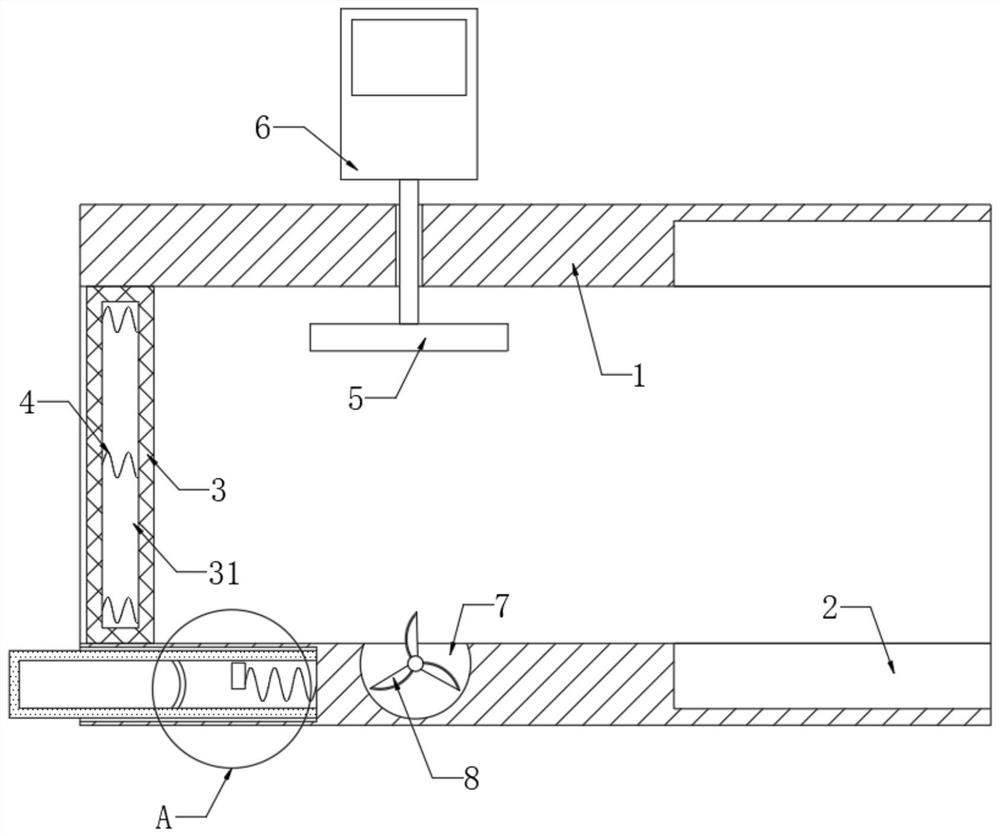

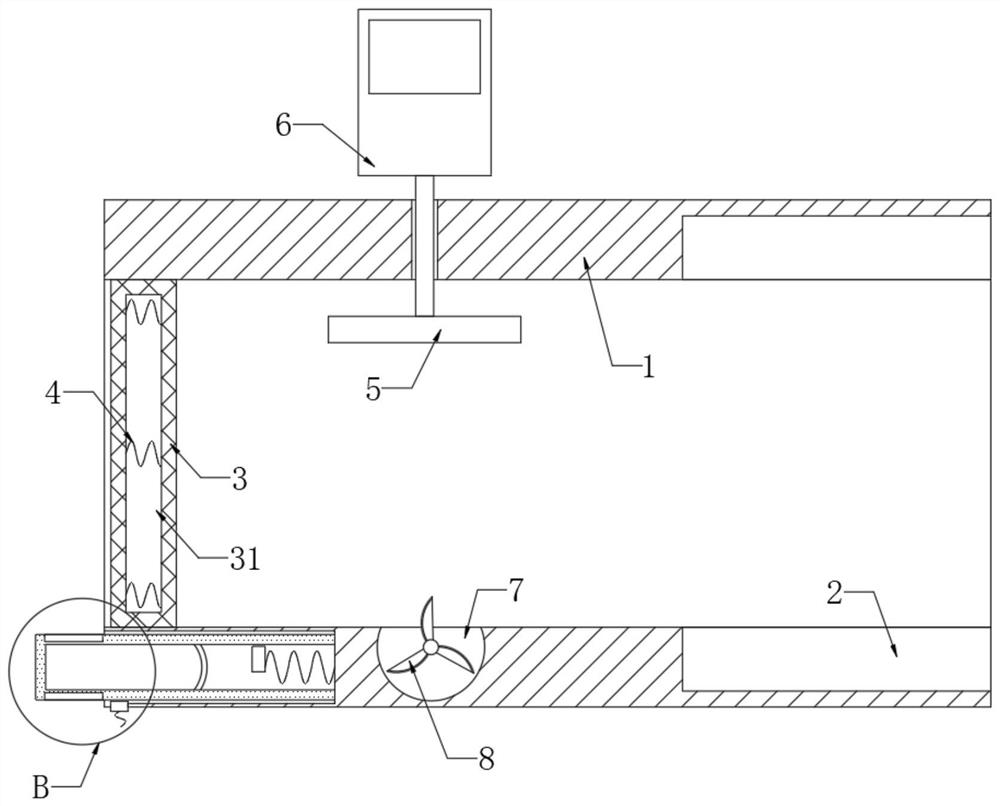

[0022] refer to Figure 1-2 , a highway mechanical and electrical equipment detection device, comprising a tube body 1, the inner wall of the tube body 1 is provided with a fan embedded groove 2, a detection tube 5 is arranged in the tube body 1, and a digital micromanometer 6 is installed on the detection tube 5, It should be noted that the connection and installation methods of the detection tube 5 and the digital micromanometer 6 are the same as those of the existing fan air volume detection device. Since they have nothing to do with the design purpose of this solution, they will not be described in detail.

[0023] A dust filter 3 is installed at the air inlet of the pipe body 1, and a strip groove 31 is provided on the side wall of the dust filter 3, and a vibrating spring 4 is embedded in the strip groove 31, and both ends of the vibrating spring 4 are connected to the strip groove. The two inner walls of 31 are fixedly connected, and the side wall of the pipe body 1 is ...

Embodiment 2

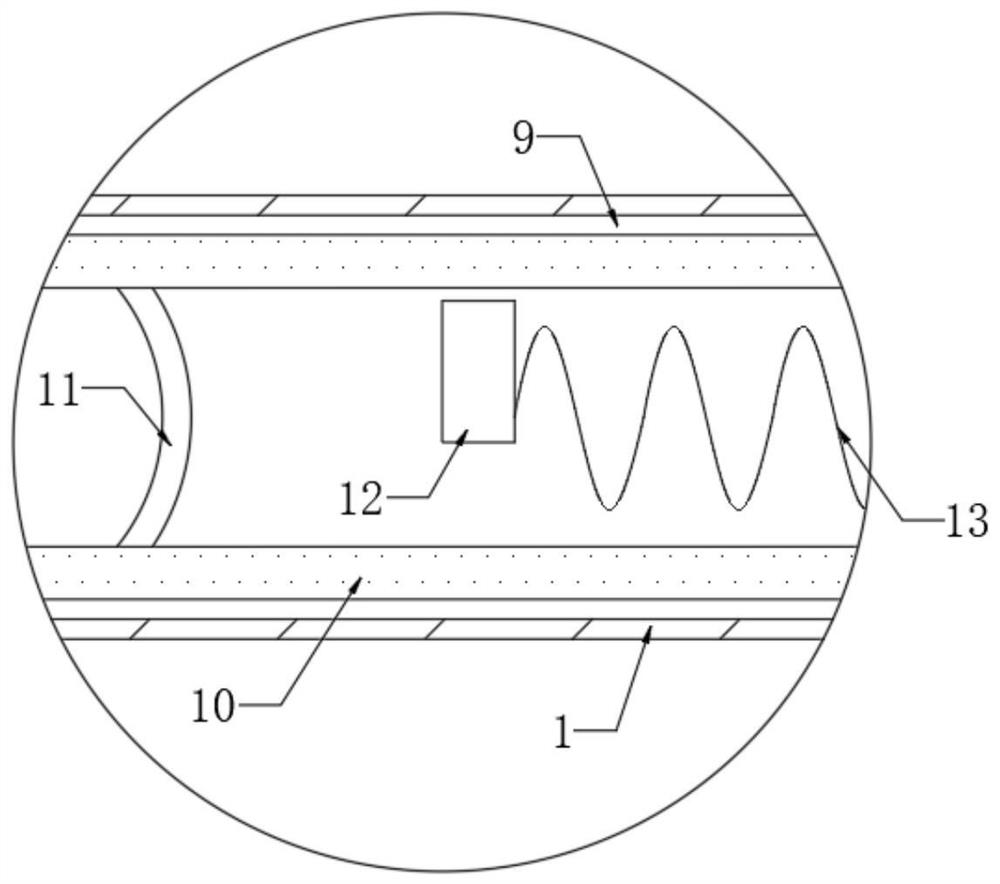

[0030] refer to Figure 3-5 , different from Embodiment 1, the sleeve 10 is rotatably connected in the storage tank 9 through a damping shaft, a plurality of dust storage tanks 101 are provided at equal intervals on the circumferential side wall of the sleeve 10, and the inner bottom of the storage tank 9 is installed with Grounding post 14.

[0031] It should be noted that the sleeve 10 is rotationally connected in the storage slot 9 through a damping shaft, so that the sleeve 10 will not rotate when there is no external force or the external force is small. When the block 12 moves back and forth, the sleeve 10 will not be rotated to cause insufficient static electricity to absorb impurities. Can be gathered into a group, and the whole body is subjected to a stronger gravity effect, and will not reattach to the outer wall of the dust filter net 3 as the airflow rises.

[0032] Further, since the generated static electricity is always gathered above the sleeve 10, and the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com