Static pressure pile machine with column pile positioning system and column pile construction method

A technology of positioning system and static pressure pile machine, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of foundation soil disturbance, large difference in shear strength and shear strength, etc., and achieve the guarantee and improvement of construction steps The effect of engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

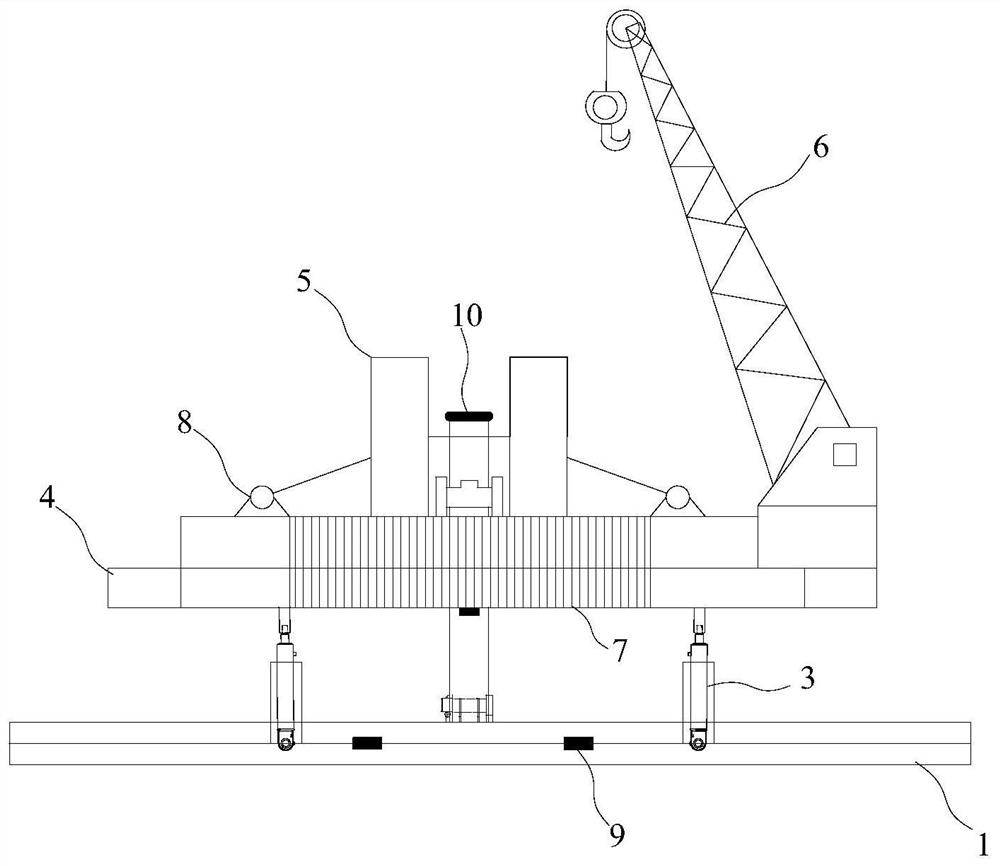

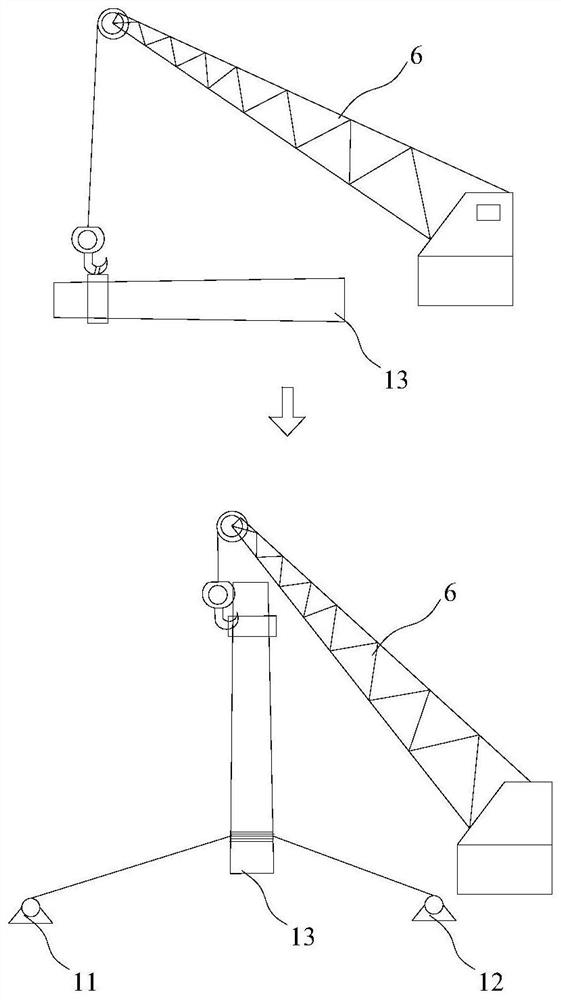

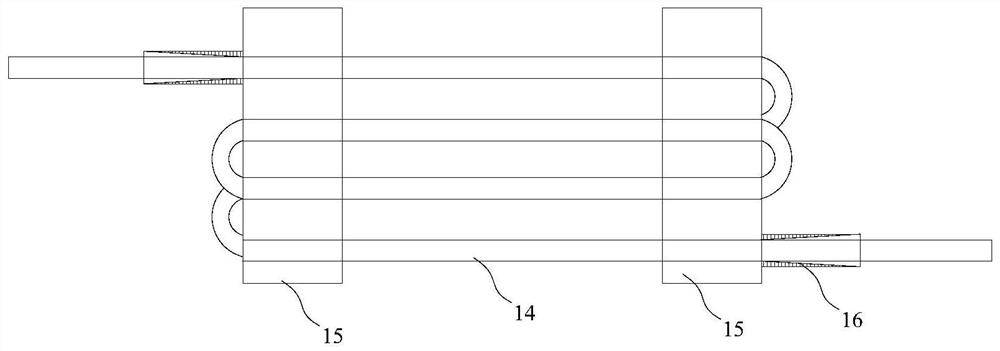

[0034] combine Figure 1 to Figure 6 As shown, a specific implementation of a static pressure pile machine with a pile positioning system and a pile construction method provided by the present invention will be described.

[0035] A static pressure pile machine with a pile positioning system, comprising a first outrigger 1, a second outrigger 2, a support cylinder 3, a workbench 4, a pile holder 5, a crane frame 6, a counterweight 7 and a positioning system , the various structures cooperate with each other to smoothly hoist the pile, and can accurately locate the axis of the pile hole to ensure that the pile sinks along the axis of the pile hole. When the pile body is inclined, the positioning device can also be corrected by the pile, and the inclined The piles are corrected. The first outrigger 1 and the second outrigger 2 are arranged in parallel to ensure the overall stability of the static pile machine, and it is convenient to carry out satellite positioning, and a coord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com