Online monitoring method for energy efficiency of drying part of paper machine

A drying section and paper machine technology, applied in the field of paper industry, can solve problems such as difficult online monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

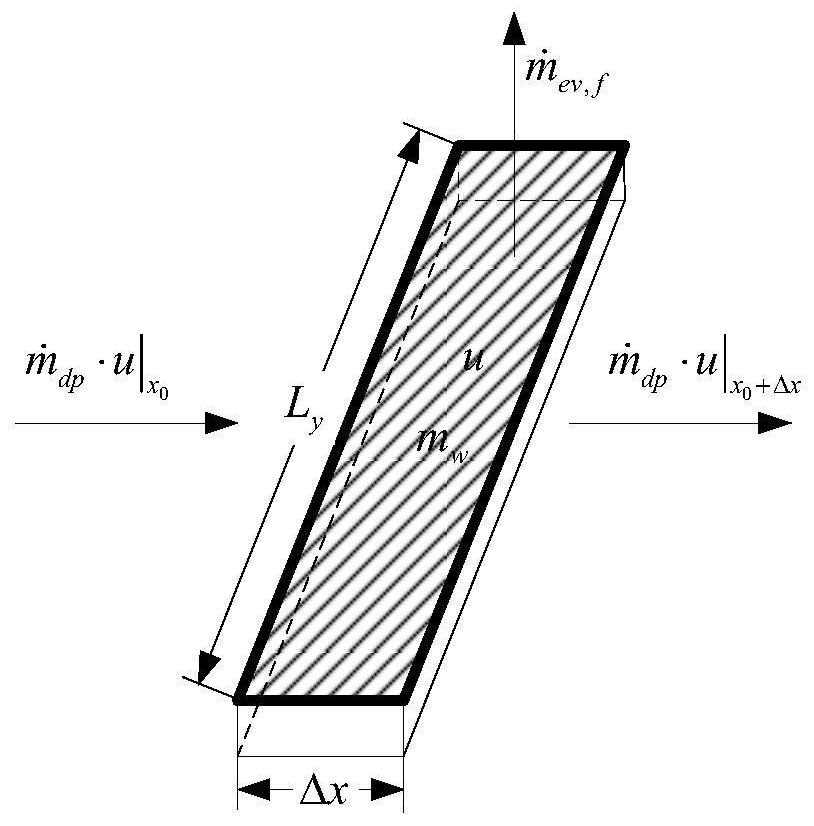

Method used

Image

Examples

Embodiment

[0131] The test object is the drying section of a paper machine that produces corrugated paper. The design capacity is 100,000 tons / year, the design speed is 500m / min, the width is 4m, and the main production quantity is 105-145g / m 2 corrugated paper. The paper machine adopts a double-row multi-dryer drying section, with a total of 48 drying cylinders (see attached Figure 6 ), the drying cylinder with a diameter of 1.5m is equipped with a spoiler bar and a fixed siphon. The steam condensate subsystem adopts a typical three-stage decompression type, #23~#48 dryers are the main steam section (I section), #10~#22 dryers are the intermediate steam section (II section), #1~# 9 is the wet section steam section (III section). The ventilation and waste heat recovery subsystem adopts a closed air hood.

[0132] The types of drying cylinders are shown in the table below:

[0133]

[0134]

[0135] Online collection of paper machine speed (V), paper weight (BW o ), paper mois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com