High-temperature-resistant and low-temperature-resistant soft sound insulation material and preparation method thereof

A sound insulation material and technology of high and low temperature resistance are applied in the field of high and low temperature resistant soft sound insulation materials and their preparation, which can solve the problems of reducing the tensile strength of sound insulation materials, affecting the appearance of products, and increasing small molecule volatiles, so as to reduce the hardness. , Improve the appearance and feel, optimize the effect of low frequency sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

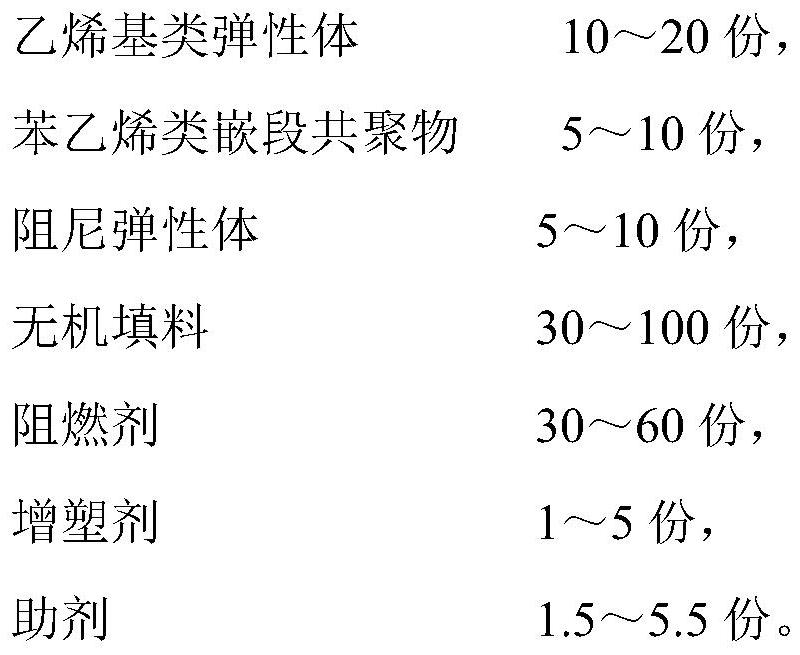

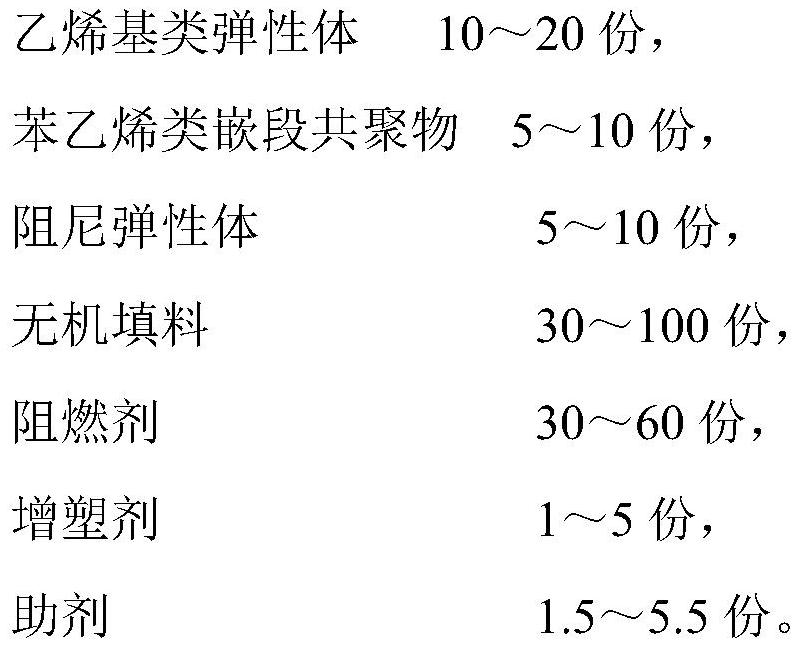

[0034] A high and low temperature resistant soft sound insulation material of the present invention comprises the following components in parts by weight:

[0035] Vinyl elastomer 15 parts,

[0036] 5 parts of styrenic block copolymer,

[0037] Damping elastic body 5 parts,

[0038] 30 parts of barium sulfate,

[0039] 45 parts of flame retardant,

[0040] 2 parts plasticizer,

[0041] 2 parts of auxiliary agent;

[0042] Among them, the vinyl elastomer is a block copolymer of ethylene and octene (INFUSE 9507), and the styrenic block copolymer is a hydrogenated styrene-butadiene-styrene block copolymer (YH-502T). The damping elastomer is styrene-ethylene branched polydiene-styrene block copolymer (HYBRAR 5127), the particle size of barium sulfate is 600 mesh, and the flame retardant is 20 parts magnesium hydroxide (800 mesh) and 25 parts hydrogen Alumina (800 mesh), plasticizer is naphthenic oil (KN4010), auxiliary agent comprises stearic acid, coupling agent, antioxidan...

Embodiment 2

[0047] A high and low temperature resistant soft sound insulation material of the present invention comprises the following components in parts by weight:

[0048] Vinyl elastomer 20 parts,

[0049] 5 parts of styrenic block copolymer,

[0050] Damping elastic body 5 parts,

[0051] 60 parts of barium sulfate,

[0052] 60 parts of flame retardant,

[0053] 2 parts plasticizer,

[0054] 2 parts of auxiliary agent;

[0055] Among them, the vinyl elastomer is a block copolymer of ethylene and octene (INFUSE 9507), and the styrenic block copolymer is a hydrogenated styrene-butadiene-styrene block copolymer (YH-502T). The damping elastomer is styrene-ethylene branched polydiene-styrene block copolymer (HYBRAR 5127), the particle size of barium sulfate is 600 mesh, and the flame retardant is 30 parts magnesium hydroxide (800 mesh) and 30 parts hydrogen Alumina (800 mesh), plasticizer is naphthenic oil (KN4010), auxiliary agent comprises stearic acid, coupling agent, antioxidan...

Embodiment 3

[0060] A high and low temperature resistant soft sound insulation material of the present invention comprises the following components in parts by weight:

[0061] Vinyl elastomer 15 parts,

[0062] 10 parts of styrenic block copolymer,

[0063] Damping elastomer 10 parts,

[0064] 30 parts of barium sulfate,

[0065] 45 parts of flame retardant,

[0066] 2 parts plasticizer,

[0067] 2 parts of auxiliary agent;

[0068] Among them, the vinyl elastomer is a block copolymer of ethylene and octene (INFUSE 9507), and the styrenic block copolymer is a hydrogenated styrene-butadiene-styrene block copolymer (YH-502T). The damping elastomer is styrene-ethylene branched polydiene-styrene block copolymer (HYBRAR 5127), the particle size of barium sulfate is 600 mesh, and the flame retardant is 20 parts magnesium hydroxide (800 mesh) and 25 parts hydrogen Alumina (800 mesh), plasticizer is naphthenic oil (KN4010), auxiliary agent comprises stearic acid, coupling agent, antioxidant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com