Synchronous double-eccentric-shaft shock excitation device and thin oil lubrication method

A vibration excitation device and double eccentric technology, applied in the direction of cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of lubricating oil leakage, increased energy consumption loss of equipment operation, etc., to avoid leakage, low work loss, good Effect of sealed design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below through specific embodiments.

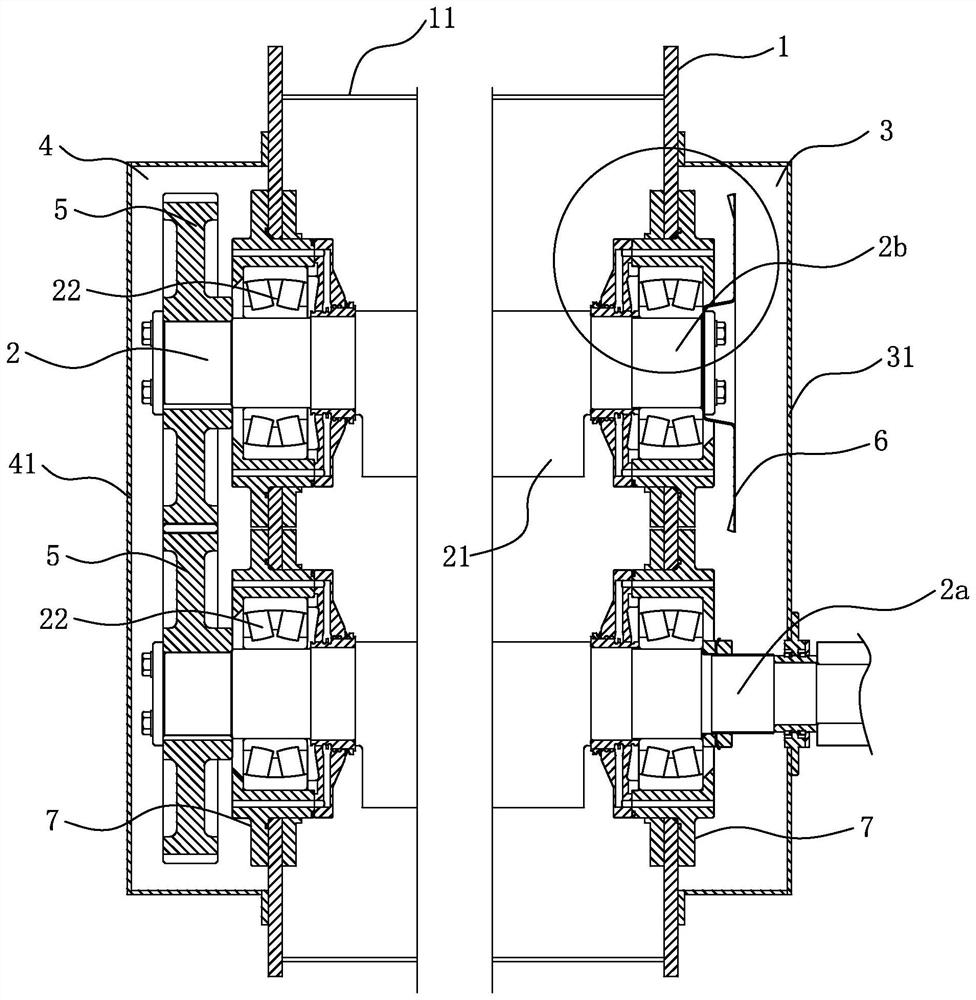

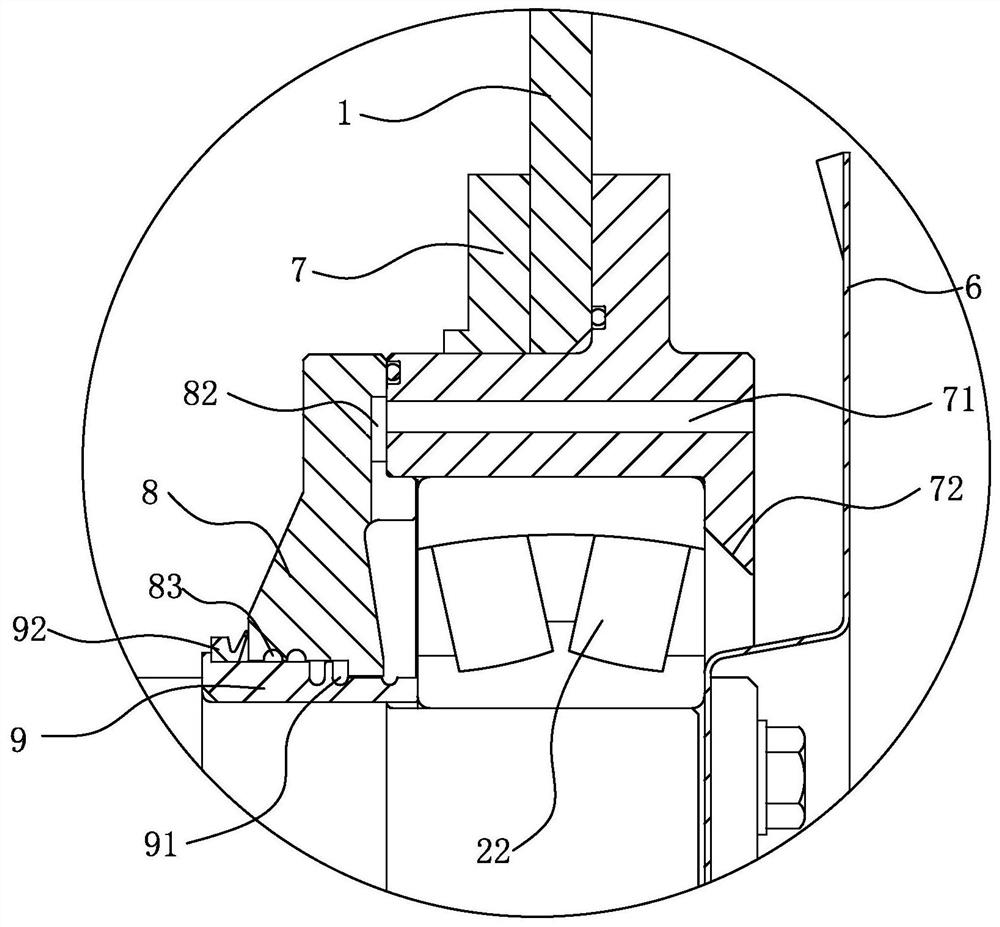

[0025] refer to Figure 1 to Figure 4 As shown, a synchronous double eccentric shaft vibration device includes a base 1, an eccentric shaft 2, a first oil tank 3, a second oil tank 4, a synchronous gear 5, an oil throwing plate 6, a bearing seat 7, a bearing gland 8, Shaft sleeve 9.

[0026] The middle section of the eccentric shaft 2 is the eccentric portion 21, and the two ends of the eccentric shaft 2 are located on the base 1 through bearings 22. The eccentric shaft 2 includes a driving shaft 2a, a driven shaft 2b, and the first oil tank 3 and the second oil tank 4 are respectively It is arranged at both ends of the eccentric shaft 2, and the end of the eccentric shaft 2 and the bearing 22 at the corresponding end are sealed inside, the first oil tank 3 and the second oil tank 4 are respectively provided with lubricating oil, and the drive shaft located in the first oil tank 3 2a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com