A vulcanization bladder mechanism and its use method

A technology of curing bladder and heating mechanism, applied in the field of tire building, can solve the problems of reducing the contact time between the heat medium and the heating element, the heat medium cannot be fully heated, and the convection effect of the heat medium is poor. Convection effect, effect of reducing vulcanization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0067] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of structure, change of proportional relationship or adjustment of size shall fall within the range covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. within range.

[0068] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invention without...

Embodiment 1

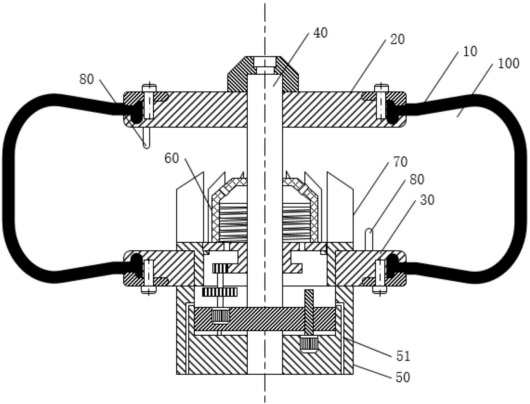

[0070] combined with Figure 1-2 , a vulcanization bladder mechanism, comprising a first heating cavity 100 that can accommodate a heat medium formed jointly by a vulcanization bladder 10, a first fixing plate 20 for fixing the vulcanization bladder 10, and a second fixing plate 30, the first heating A temperature sensor 80 is provided in the cavity 100, the center of the first fixed plate 20 is fixedly connected to the operating shaft 40, the bottom of the second fixed plate 30 is connected to the first housing 50, and the operating shaft 40 slides through the second At the center of the fixed plate 30 and the first housing 50, a heating mechanism 60 can be rotatably arranged above the center of the second fixed plate 30. The heating mechanism 60 is a closed structure, and a heating medium is provided at the bottom. The first through hole 624 has a second through hole 614 connected to the first heating chamber 100 at the top, and a rotatable dispersing mechanism 70 is provide...

Embodiment 2

[0080] In this embodiment, the heater 61 in the first embodiment is optimized and improved so that it can rotate in coordination with the dispersing mechanism 70 to increase the convection velocity of the heat medium. The specific technical scheme is as follows:

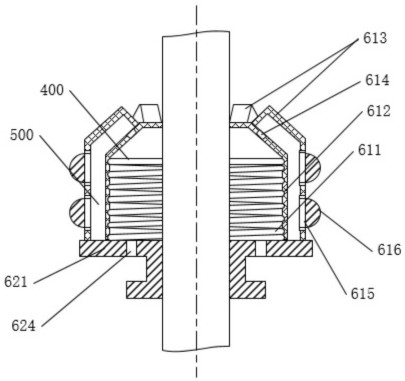

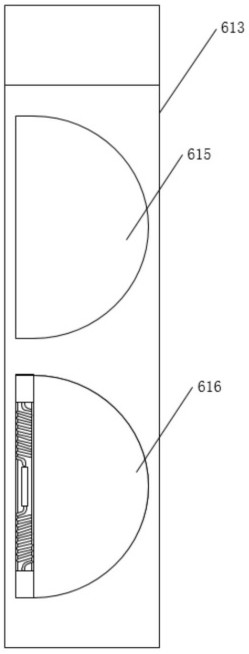

[0081] combined with Figure 3-6 , the heater 61 includes a heating coil 611, a second casing 612 and a sector block 613, the second casing 612 and the sector block 613 are made of heat-conducting materials, and the sector block 613 is fixed on The second housing 612 is provided with a distribution cavity 500 outside and inside, the second through hole 614 communicates with the second heating cavity 400 and the distribution cavity 500, and the outer wall of the sector block 613 is provided with a third The through hole 615, the third through hole 615 is a semicircular through hole and the inside is provided with a turning mechanism 616 that can be turned radially inward or outward by 90° to open the third through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com